Multifunctional composites could help achieve structural supercapacitors for EVs

In a recent study, functionalized graphene/nanofiber electrodes showed 2X modulus, strength and 5-10X multifunctional efficiency.

Structural batteries and structural supercapacitors offer a potential solution for electric vehicles (EVs) because they can not only handle structural loads but also store energy and/or produce power. For future ground and air mobility, this offers reduced weight and volume for structures and batteries, as well as more miles between recharging. However, current electrodes for batteries and supercapacitors suffer from poor mechanical performance because they are typically made from brittle materials.

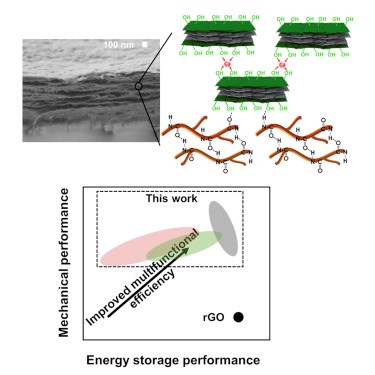

A team led by Texas A&M University (College Station, Tex. U.S.) chemical engineer, Jodie Lutkenhaus, has produced structural supercapacitor electrodes using reduced graphene oxide (rGO), innovative chemistry and aramid nanofibers to mimic the natural material nacre, achieving Young’s modulus and ultimate tensile strength that are 220% and 255%, respectively, higher versus pure rGO electrodes, as well as multifunctional efficiency values of 5–13.6 compared to current electrodes at <1.

Nacre-like multifunctional composite

In an article published in the journal , Lutkenhaus and her team describe using dopamine to functionalize (chemically bond to) rGO and then combine this material with aramid nanofibers to form a composite. The paper explains, “We hypothesized that nature-inspired materials could transform the poor mechanical properties of supercapacitor electrodes into those mimicking nacre, bone, or wood to realize exceptionally high values of multifunctional efficiency.”

Nacre (mother-of-pearl) consists of 95 vol % aragonite (calcium carbonate), chitin, and proteins yet exhibits toughness three orders of magnitude higher than aragonite alone. Its superior mechanical performance results from its hierarchical composite structure: its constituent particles and matrix are organized differently at each geometric scale or level (e.g., nano-, micro-, meso-, macro-) and combine with efficient interfaces between these levels to achieve high modulus and strength while mitigating crack propagation (see the blog “Magnetic 3D printing the next generation of tailored composites”).

The Lutkenhaus team knew that graphene-based nacre-mimicking electrodes have been shown to perform very well electrically. The challenge was to improve their mechanical properties. The team sought to use the hormone and neurotransmitter dopamine to functionalize rGO. Dopamine also self-polymerizes into the highly adhesive polymer polydopamine (PDA). Dopamine mimics the structure of adhesive proteins in nacre-lined mussels, while PDA has been utilized in Li-ion batteries and supercapacitors as an electrode material, separator modifier and binder. However, only a handful of studies have focused on incorporating PDA in rGO composites.

As explained in the Matter technical paper, “We sought to combine for the first time the excellent mechanical properties of PDA-modified rGO with high-modulus, high-tensile-strength Kevlar aramid nanofiber to improve the multifunctional efficiency.” Aramid nanofibers have also been used in a variety of applications including energy storage.

Good structural properties

Nacre-mimicking structural supercapacitor electrodes based on branched aramid nanofibers and dopamine-functionalized rGO sheets were fabricated using vacuum filtration and their performance was evaluated. The excellent mechanical properties exhibited are reported to result from increased hydrogen bonding caused by the dopamine functionalization and chelation caused by Ca2+ ions.

The Lutkenhaus team reports that this approach is applicable to other nacre-mimicking structures which should lead to a new stronger multifunctional family of nature-inspired materials. “Future work should focus on improving the electrochemical performance, either by adding porosity to improve the ionic mobility or by adding a pseudocapacitive material to enhance energy density. To the best of our knowledge, the obtained Young's modulus and multifunctional efficiency is the highest among the electrically conductive composites with low aramid nanofiber content. This leads to strong structural supercapacitor electrodes with high electrochemical performance.”

Related Content

Alformet white paper examines untapped potential of TPC electric motor sleeves

The resource, geared toward electric motor and composites specialists, discusses rotor and stator sleeve design considerations, manufacturing insights and more.

Read MoreSMC composites progress BinC solar electric vehicles

In an interview with one of Aptera’s co-founders, CW sheds light on the inspiration behind the crowd-funded solar electric vehicle, its body in carbon (BinC) and how composite materials are playing a role in its design.

Read MoreSwancor applies EzCiclo recycling resin to Liux EV prototype

Cooperation with Spanish automotive startup has achieved automotive parts comprising EzCiclo RH512 thermoset resin and linen fiber that can be fully separated, adjusted and returned into circularity.

Read MoreComposites end markets: Batteries and fuel cells (2024)

As the number of battery and fuel cell electric vehicles (EVs) grows, so do the opportunities for composites in battery enclosures and components for fuel cells.

Read MoreRead Next

Cutting 100 pounds, certification time for the X-59 nose cone

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.

Read MoreCeramic matrix composites: Faster, cheaper, higher temperature

New players proliferate, increasing CMC materials and manufacturing capacity, novel processes and automation to meet demand for higher part volumes and performance.

Read MoreScaling up, optimizing the flax fiber composite camper

Greenlander’s Sherpa RV cab, which is largely constructed from flax fiber/bio-epoxy sandwich panels, nears commercial production readiness and next-generation scale-up.

Read More