Market report published on resin infusion in aerospace manufacturing

Based on industry interviews, this research was conducted as part of a multi-phase effort conducted by Mississippi State University’s Advanced Composites Institute (ACI).

The authors at Mississippi State University (MSU, Starkville, Miss., U.S.) Advanced Composites Institute (ACI), as part of a multi-phase FAA-funded effort through the FAA Joint Center of Excellence for Advanced Materials (JAMS), have published a final report for a study evaluating the state of the industry for resin infusion in aerospace manufacturing.

According to the , this work is the first academic application describing the prioritization methodology for resin infusion research using a New Product Blueprinting (NPB) process developed by the AIM Institute. This market study process included 30 interviews spanning the value stream, including interviewees from OEMs, raw material suppliers, Tier 1 suppliers, new and experienced users of resin infusion, and providers of machine solutions.

The overall goal is to examine industry gaps on the use, knowledge and satisfaction of using resin infusion techniques within the aerospace industry, and to identify research topics in this area.

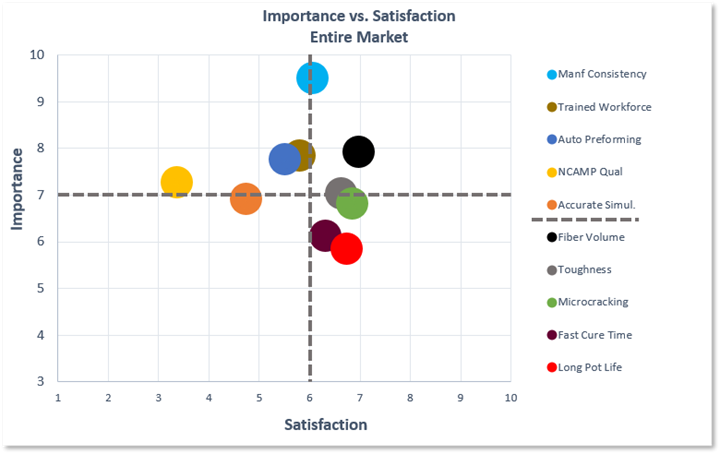

An example of data from the FAA’s market study report on resin infusion within the aerospace manufacturing industry. Interviewees were asked to rank the importance and satisfaction of each of the topics listed at right on a scale of 1 to 10. According to this study, those interviewed demonstrated that NCAMP qualification and accurate simulation are of high importance within the industry, but satisfaction in these areas is low. Photo Credit: MSU ACI

The results of this study are directing further work by ACI and its partners. For example, in reaction to the need for more accurate simulation, a recent project measured the permeability of dry fabrics to serve as inputs for simulating infused composite aerospace parts more efficiently. In this ongoing study, a large-scale wing box will be simulated using inputs from permeability measurements prior to infusion.

In addition, MSU has set up a new Mississippi Advanced Composites Training Center to fill the gap for a better trained workforce.

Find the full report .

Related Content

-

Partners recycle A350 composite production waste into adjustable-length rods for MFFD

Herone, Spiral RTC, Teijin Carbon Europe and Collins Aerospace Almere recycle A350 thermoplastic composite clips/cleats waste into rods for the all-thermoplastic composite Multifunctional Fuselage Demonstrator’s crown.

-

Syensqo becomes new Solvay specialty materials company

Syensqo represents what was Solvay Composite Materials, focused on delivering disruptive material technologies and supporting growing customer needs.

-

ECOHYDRO project to enable recyclable composites for hydrogen storage

With the involvement of two schools from the Institut Mines-Télécom, the 4-year project aims to improve the intrinsic properties of a composite material based on Elium via four concrete demonstrators.

.jpg;width=70;height=70;mode=crop)