Jaguar Land Rover undertakes composite program for EV lightweighting

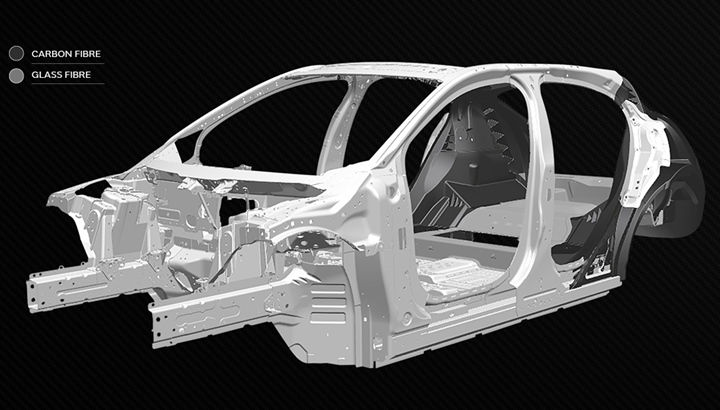

U.K. Tucana project plans to replace steel and aluminum with composites for vehicle structures.

Photo Credit: JLR

Jaguar Land Rover (JLR, Coventry, U.K.) has long been a proponent of lightweighting vehicles through the use of aluminum, but the company is clearly material-neutral as it is leading a consortium of companies and researchers in the U.K. Tucana project, a four-year undertaking with the objective of developing lightweight structures.

Jaguar Land Rover’s objective is to reduce vehicle stiffness by 30%, cut weight by 35 kilograms (77 pounds) and improve the crash safety structure. Much of this is to be achieved by replacing steel and aluminum structures with those made with composites.

Lighter weight structures are important for electric vehicles, as reduced mass can mean either smaller batteries or extended range.

Marcus Henry, research manager at Jaguar Land Rover, says, “This project will allow the true environmental credentials of electric vehicles to be realized by enabling wider adoption of the technology and will propel Jaguar Land Rover and the U.K. supply chain into a world-leading position in low-carbon technology.”

An overarching goal is to cut CO2 emissions by 4.5 million tonnes (4.96 million tons) between 2023 and 2032.

Other members of the consortium are: Warwick Manufacturing Group (WMG), Expert Tooling & Automation, Broetje-Automation UK, Toray International UK, CCP Gransden and The Centre for Modelling & Simulation (CFMS).

Jaguar Land Rover expects to have a fleet of Tucana test vehicles on the road by 2022.

Jaguar Land Rover currently offers one full EV, the Jaguar I-PACE, but the Jaguar brand and the Land Rover brand offer hybrid versions of several models.

Related Content

-

Al Seer Marine, Abu Dhabi Maritime unveil world’s largest 3D-printed boat

Holding the new Guinness World Record at 11.98 meters, the 3D-printed composite water taxi used a CEAD Flexbot to print two hulls in less than 12 days.

-

Owens Corning to sell glass fiber business to Praana Group

Transaction with India-based holding group completes Owens Corning’s previously announced strategic review of the business, strengthens its focus on residential and commercial building products.

-

High-tension, vertical filament winding enables affordable flywheel energy storage system

French startup Energiestro’s prototype solar energy flywheel-based storage system aims to reduce costs with glass fiber composites and prestressed concrete.

.jpg;width=70;height=70;mode=crop)