Hexagon Digital Wave requalifies Type IV cylinders for RNG/CNG transportation module OEM

Requalification is performed via modal acoustic emission (MAE) which identifies structural integrity flaws present in composite pressure vessels, enhancing safety and testing standards.

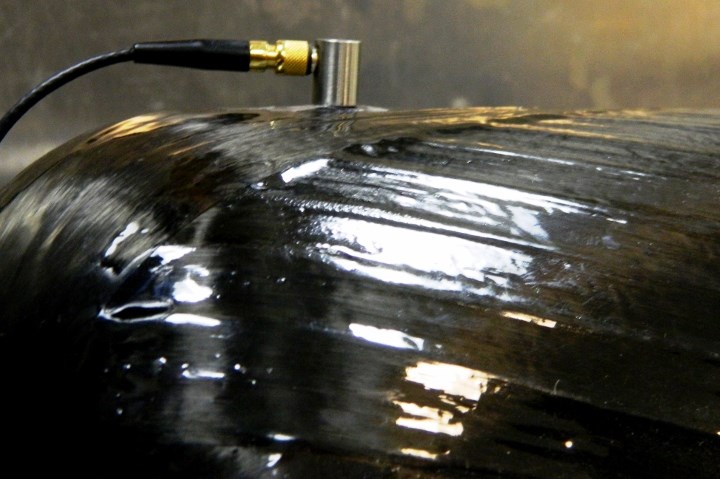

Photo Credit: Hexagon Digital Waves

(Centennial, Colo., U.S.), a business of Hexagon Composites (Alesund, Norway), has signed a commercial service agreement with a North American Type IV renewable and compressed natural gas (RNG/CNG) transportation module OEM. More specifically, the agreement covers modal acoustic emission (MAE) requalification of the OEM’s RNG/CNG modules, which is set to begin in Q3 2021. According to Hexagon Digital Wave, MAE enables the requalification of Type IV composite cylinders without removal from the module, resulting in reduced downtime and operator overhead. The commercial service agreement has a potential value of $2 million (approximately NOK 17 million).

“This commercial service agreement is another step in creating a unified expectation of safety and testing standards in the gaseous transport industry,” says Ryan Pennock, head of marketing and business development at Hexagon Digital Wave. “Our goal is to create a benchmark in digital safety in the compressed gas transportation sector, a vision OEMs, operators and end users alike will benefit from. Signing this commercial service agreement is another step on this journey.”

MAE uses advanced electronics and sensors that capture broadband waveforms and specialty algorithms to identify if there are any structural integrity flaws present in composite pressure vessels. MAE is compliant to the Department of Transportation/Pipeline of Hazardous Materials Safety Administration and Transport Canada regulations. Testing using the MAE technology eliminates venting of contents to the atmosphere, thereby minimizing environmental impact.

Hexagon Digital Wave adds that a significant increase in customer demand for compressed gas transport is driving module owners to seek safe, yet time-efficient methods of cylinder requalification. The company’s MAE technology is said to meets these needed requirements, and when deployed alleviates pain points for owners/operators and module OEMs alike.

Related Content

-

Development of a composite liquid hydrogen tank for commercial aircraft

Netherlands consortium advances cryogenic composites testing, tank designs and manufacturing including AFP, hybrid winding, welding of tank components and integrated SHM and H2 sensors for demonstrators in 2025.

-

ECOHYDRO project to enable recyclable composites for hydrogen storage

With the involvement of two schools from the Institut Mines-Télécom, the 4-year project aims to improve the intrinsic properties of a composite material based on Elium via four concrete demonstrators.

-

Composite bipolar plates provide 81% improvement to hydrogen fuel cell power density

Ultra-thin CFRTP plates developed by Hycco achieve a 7.5 kilowatt/kilogram power density, high durability for fuel cells in long-flight drone and heavy-mobility applications.