DLR develops concept for final assembly line with artificial intelligence

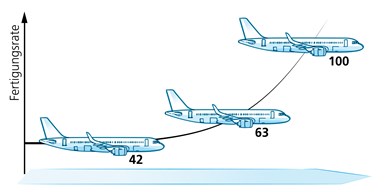

High-rate production enabled by pre-selection of assembly-ready components, without manual compensation measures, based on neural network training.

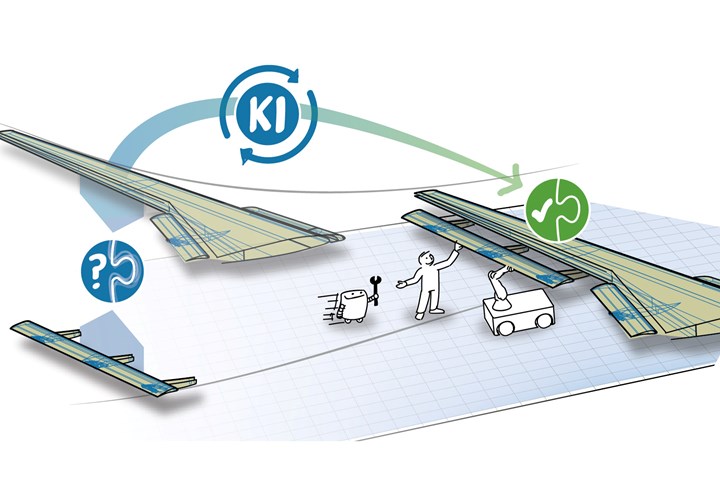

A final assembly line with artificial intelligence (künstliche intelligenz, or KI) can be implemented, with assemblability guaranteed at all times. Photo credit: , Institute for Composite Structures and Adaptive Systems.

In a 2021 article by Dr. Ing. Lennart Weiss, of the DLR Institute for Composite Structures and Adaptive Systems (Braunschweig, Germany), manual compensation procedures — for example, shimming —and the resulting delays are a thing of the past. Each assembly can be joined immediately using artificial intelligence, because a clever pre-selection of the components reduces excessively large tolerances at the connection areas. Even high-rate production is possible thanks to the “plug and fly” principle. DLR envisions the complete introduction of this expert system into series production.

Independent assembly decision

In an expert system, the artificial intelligence selects individual parts that can be assembled independently. The connection dimensions and their tolerances determine whether the components can be assembled. The neural network evaluates the recorded parameters, draws on its "experience" and signals a positive or negative assembly process. The neural network achieves empirical values ​​through so-called monitored training cycles (supervised learning). This often requires a large number of independent assembly scenarios or data points. The greatest challenge is the limited availability of this training data for assembly processes in the final assembly line.

Computer-aided for small batch sizes

First and second step regression functions, where AI (shown here as KI for künstliche intelligenz) generates the final regression functions.

A two-stage process solves the problem in dealing with small lot sizes. Thefirst step of the process consists of training several neural networks. They represent various preselected approach functions. Their training for the best possible regression of the data points leads to the first "experiences". However, the influence of the preselection of shape functions on the regression result is too great. Therefore, in the second step, the algorithm is free to generate its own approach function based on its “experiences” from the first step and to carry out the training with this again.

The algorithm learns from its training experience and independently determines a regression function that is sufficiently predictive even for small batches. The artificial intelligence runs through this computer-aided process after each assembly, so that the wealth of experience grows with each positive or negative assembly process. This improves the prediction quality of the expert system with each assembly process carried out.

The learning expert system enables economical high-rate production based on the “plug & fly” principle. Complex compensation measures and downtime in the assembly line are a thing of the past. The expert system evaluates, in real-time, specific component information, such as tolerances at joints and provides presettings for guaranteed assembly as a recommendation for action to the assembler. Photo Credit: .

The learning expert system accompanies the final assembly line in series production. The knowledge gained can be used both for new flexible assembly concepts in the factory of the future and for a new construction philosophy for the designer of the future.

This article follows on from Weiss’ 2020 article, “Flexible Cooperation - with a learning expert system for intelligent assembly”.

Related Content

UniSQ, iLAuNCH Trailblazer program drive digital twin innovation for composite repairs

Working with Boeing Australia, Memko and Dassault Systèmes, the University of Southern Queensland (UniSQ) has developed a digital twin via the 3DEXPERIENCE platform, digitizing processes that could lead toward more efficient and effective maintenance, repair and operations of future fleets.

Read MoreIMDEA introduces digital twin for real-time analysis of composite materials production

Newly designed digital twin by IMDEA and Technical University of Madrid researchers enables manufacturers to see inside composite materials as they are being produced, facilitating early detection of faults.

Read MoreHow AI is improving composites operations and factory sustainability

Workforce pain points and various logistical challenges are putting operations resilience and flexibility to the test, but Industry 4.0 advancements could be the key to composites manufacturers’ transformation.

Read MoreAerotech Academy Puglia is inaugurated at Leonardo Aerospace site in Grottaglie, Italy

Joining the Leonardo MaTeRIA Lab and Joint Lab with Syensqo, this aerostructures training course will be 75% materials science and structural design/analysis, 25% digital transformation and AI.

Read MoreRead Next

Next-gen fan blades: Hybrid twin RTM, printed sensors, laser shock disassembly

MORPHO project demonstrates blade with 20% faster RTM cure cycle, uses AI-based monitoring for improved maintenance/life cycle management and proves laser shock disassembly for recycling.

Read MoreCutting 100 pounds, certification time for the X-59 nose cone

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.

Read MoreScaling up, optimizing the flax fiber composite camper

Greenlander’s Sherpa RV cab, which is largely constructed from flax fiber/bio-epoxy sandwich panels, nears commercial production readiness and next-generation scale-up.

Read More