Continuous Composites awarded Phase II SBIR contract for full-scale unmanned aircraft wing

High-performance thermoset resins and continuous carbon fiber via the company’s CF3D process will be used to fabricate an organically integrated wing spar and rib configuration into a single component.

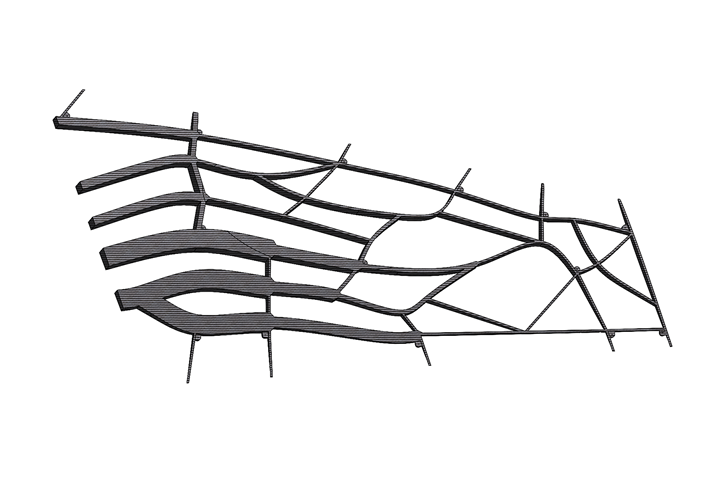

Single-component, organically integrated wing spar and rib configuration. Photo Credit: Continuous Composites

Continuous Composites (Coeur D’Alene, Idaho, U.S.) announced on May 20 that it has been awarded a $750K Phase II Small Business Innovation Research (SBIR) contract to demonstrate its patented Continuous Fiber 3D Printing (CF3D) manufacturing process for a Department of Defense (DoD) multifunctional structural composite application through collaboration with the (AFRL, Dayton, Ohio, U.S.). The SBIR topic focuses on Attritable Structures, Engines and Sensors of Autonomous Unmanned Aerial Systems (UAS) and Space Systems.

According to Continuous Composites, accelerating change while increasing complexity, unpredictability and mass, a primary objective of the United States Air Force (USAF) Science and Technology Strategy, is hampered by aerospace composite manufacturing techniques which require significant manufacturing time by a skilled workforce. Continuous Composites’ CF3D technology, however, is an automated manufacturing solution that significantly reduces cost, weight and lead time while opening new capabilities for complex structural solutions. The company says its capabilities to introduce low-cost, topology optimized structures directly align with Low-Cost Attritable Aircraft Technology/Platform (LCAAT/P) initiatives.

The primary technical objectives of this contract are to fabricate an organically integrated wing spar and rib configuration into a single component, resulting in a completely unitized wing frame. The design for the topology-optimized wing structure will be generated using a disruptive AI software solution, Generative Design, in collaboration with the Advanced Structural Concepts division in the Aerospace Systems Directorate of AFRL.

Design inputs include CF3D’s print capabilities combined with the mechanical properties of high-performance thermoset resins and continuous carbon fiber. The CF3D printed, unitized frame will be assembled with composite wing skins resulting in a full-scale wing structure for an unmanned aircraft. A static wing test will be performed by AFRL to evaluate performance and Continuous Composites says it will document process data that will be compared to more traditional fabrication and assembly processes.

“This program provides us the opportunity to collaborate with an innovative team and their disruptive manufacturing technology to further develop CF3D’s capabilities for mission readiness,” says Craig Neslen – AFRL/RXMS LCAAT manufacturing lead. “We are committed to evaluating and maturing Continuous Composites’ technology for advanced aerostructures which will enable us to meet the challenging manufacturing demands of the DoD.”

The contract will further leverage CF3D as an automated commercial process providing a responsive solution to unpredictable manufacturing surge requirements within the DoD. This demonstration will showcase the emerging capabilities of CF3D by reimagining aerostructures while using a low-cost, fully automated manufacturing technology to print a monolithic composite component. This application also reportedly demonstrates CF3D with its advanced material solutions developed in collaboration with their materials partner Arkema (Cologne, Germany).

“We are honored to receive this Phase II SBIR contract directly through the DoD,” says Tyler Alvarado, CEO of Continuous Composites. “The AFRL is a long-standing customer who recognized early the disruptive capabilities of CF3D. Through this contract and others, we are committed to transforming DoD operational capabilities.”

Related Content

-

Plant tour: Airbus, Illescas, Spain

Airbus’ Illescas facility, featuring highly automated composites processes for the A350 lower wing cover and one-piece Section 19 fuselage barrels, works toward production ramp-ups and next-generation aircraft.

-

Otto Aviation launches Phantom 3500 business jet with all-composite airframe from Leonardo

Promising 60% less fuel burn and 90% less emissions using SAF, the super-laminar flow design with windowless fuselage will be built using RTM in Florida facility with certification slated for 2030.

-

First Airbus A350 crash confirmed in Haneda

Shortly after touch-down, a JAL A350-900 aircraft recently collided with a De Havilland Canada Dash 8. Exact circumstances are still unknown.