Cabin Management Systems leverages Markforged carbon fiber 3D printers for FAA-compliant end-use parts

Cabin Management Solutions (CMS) incorporates the Markforged X7 printer and Onyx FR material for high-quality, rapid parts production for cabin management maintenance, upgrades and replacements for luxury aircraft.

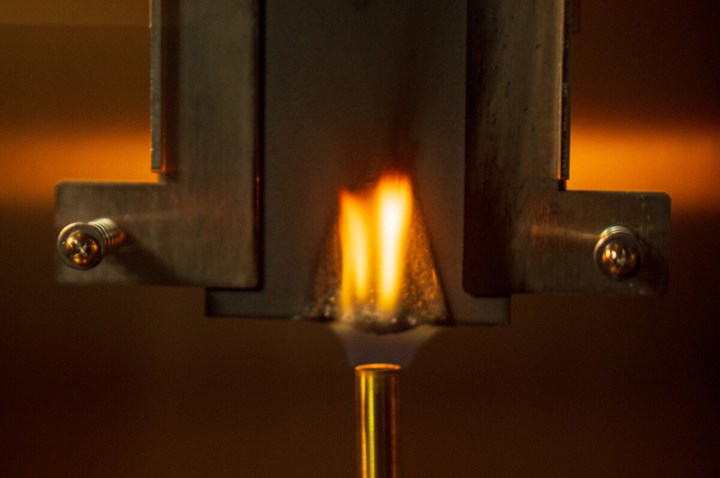

CMS uses Onyx FR to deliver custom parts that are high strength, low weight, and flame retardant. Photo Credit: Markforged, CMS

(Watertown, Mass., U.S.), creator of the integrated metal and carbon fiber additive manufacturing platform, , has announced that (CMS, Conroe, Texas, U.S.), a privately held in-flight cabin management and entertainment systems company, is using two to print high-quality, end-use parts for cabin management maintenance, upgrades and replacements for luxury aircraft.

CMS was founded in 2019 and works frequently with aircraft maintenance, repair and overhaul (MRO) companies and individual aircraft owners to design and develop cabin control and entertainment systems for luxury, private and business jets. CMS uses Onyx FR to fabricate custom parts that are high strength, low weight, flame retardant and FAA compliant. According to Markforged, the X7 printers retain improved the quality and speed of parts production, enabling CMS to complete a higher volume of jobs more quickly and earning it a reputation for fast time to market, high-quality deliverables and rigorous testing and certification process.

“In the aerospace industry, quality and on-the-fly adaptability are crucial to success,” says Jeff Pike, VP of engineering at CMS. “We often have to produce low-volume, high-value parts from scratch which can be time- and labor-intensive. Markforged’s X7 allows us to do this quickly and more efficiently, while ensuring functionality and retaining the upscale aesthetics expected in luxury aircraft.”

On one aircraft in particular, the CMS team printed at least 100 different parts, including approximately 20 light switch panels, a cabin climate controller, latches, release buttons, USB-C and drop-in USB-A chargers and adjustable touch screen brackets — all using the X7 printer. In order to meet the specific demands of its luxury-oriented customers, the CMS team then adds an extra level of customization via overlays that mimic upscale cabin surfaces including gold metal electroplating, wood veneer and more. CMS says its process ensures the end product is FAA compliant while going above and beyond customers’ expectations for aesthetics.

Moving forward, CMS plans to continue leveraging Markforged’s additive solutions, especially with Markforged’s recent release of Onyx FR-A and Carbon Fiber FR-A, aerospace-ready versions of its Onyx FR and Carbon Fiber FR materials. These two new materials come with full material traceability and are undergoing qualification on the Markforged X7 printer via a program conducted by the National Center for Advanced Materials Performance (NCAMP), one of two bodies authorized by the FAA to qualify materials for flight. Once this process is complete, CMS will be able to increase its overall production speed, which will result in adding even more jobs to its already expanding pipeline.

“CMS has incorporated Markforged technology into their business in a way that enables them to maintain their reputation for high-quality and give themselves competitive advantage,” says Markforged President and CEO Shai Terem. “Our technology is not only about printing parts faster and at the point of need, but also giving aerospace manufacturers the confidence that their parts meet the regulatory and functional requirements of their industry.”

To read more about CMS’s use of Markforged printers, visit the company’s .

Related Content

Plant tour: Airbus, Illescas, Spain

Airbus’ Illescas facility, featuring highly automated composites processes for the A350 lower wing cover and one-piece Section 19 fuselage barrels, works toward production ramp-ups and next-generation aircraft.

Read MoreBladder-assisted compression molding derivative produces complex, autoclave-quality automotive parts

HP Composites’ AirPower technology enables high-rate CFRP roof production with 50% energy savings for the Maserati MC20.

Read MoreInfinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MoreDevelopment of a composite liquid hydrogen tank for commercial aircraft

Netherlands consortium advances cryogenic composites testing, tank designs and manufacturing including AFP, hybrid winding, welding of tank components and integrated SHM and H2 sensors for demonstrators in 2025.

Read MoreRead Next

Cutting 100 pounds, certification time for the X-59 nose cone

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.

Read MoreNext-gen fan blades: Hybrid twin RTM, printed sensors, laser shock disassembly

MORPHO project demonstrates blade with 20% faster RTM cure cycle, uses AI-based monitoring for improved maintenance/life cycle management and proves laser shock disassembly for recycling.

Read MoreUltrasonic welding for in-space manufacturing of CFRTP

Agile Ultrasonics and NASA trial robotic-compatible carbon fiber-reinforced thermoplastic ultrasonic welding technology for space structures.

Read More