Blue Origin to team up with Lockheed Martin, Northrop Grumman and Draper on lunar lander

Proposed lunar landing system to be considered for NASA’s Artemis program, which seeks to return humans to the moon by 2024.

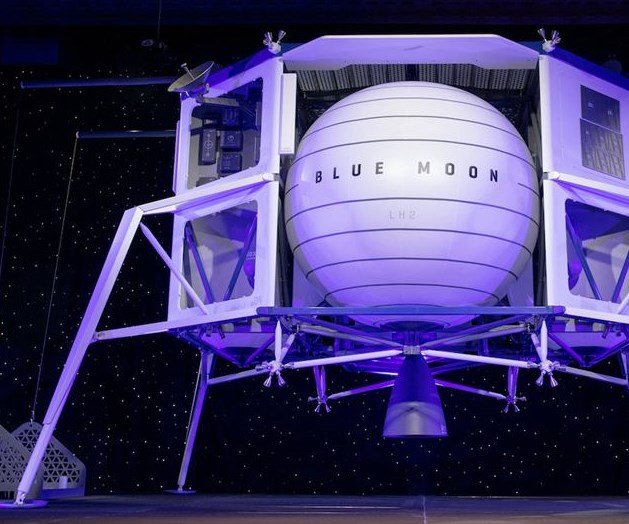

Source | Blue Origin

Jeff Bezos, founder of Blue Origin (Kent, Wash., U.S.), on Oct. 22 at the 70th International Astronautical Congress in Washington, D.C., U.S., announced that the company would partner with Lockheed Martin (Bethesda, Md., U.S.), Northrop Grumman (Falls Church, Va., U.S.) and Draper (Cambridge, Mass., U.S.) on a lunar landing system that could be used for NASA’s Artemis program which seeks to return humans to the moon by 2024. NASA announced in September it is seeking proposals for human lunar landing systems designed and developed by American companies for the program.

The proposed lunar landing system will comprise Blue Origin’s Blue Moon lunar lander, a “Transfer Element” vehicle provided by Northrop Grumman (Falls Church, Va., U.S.) that will position the landing system in lunar orbit, and an “Ascent Element” vehicle provided by Lockheed Martin that will return astronauts to lunar orbit from the Moon’s surface. A descent guidence system and flight avionics will be provided by Draper.

Blue Origin’s Blue Moon lunar lander is reportedly capable of delivering multiple metric tons of payload to the lunar surface based on configuration and mission. It is powered by the company’s new BE-7 engine, which is designed for large lunar payload transport and reportedly delivers 40 kN (10,000 lbf) of thrust using a combination of liquid oxygen and liquid hydrogen propellants.

Related Content

-

Infinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

-

First Airbus A350 crash confirmed in Haneda

Shortly after touch-down, a JAL A350-900 aircraft recently collided with a De Havilland Canada Dash 8. Exact circumstances are still unknown.

-

Welding is not bonding

Discussion of the issues in our understanding of thermoplastic composite welded structures and certification of the latest materials and welding technologies for future airframes.