Bercella, Beamit partner to research composite aerospace, defense applications

The Italy-based companies plan to focus on novel joining methods between additively manufactured and CFRP parts.

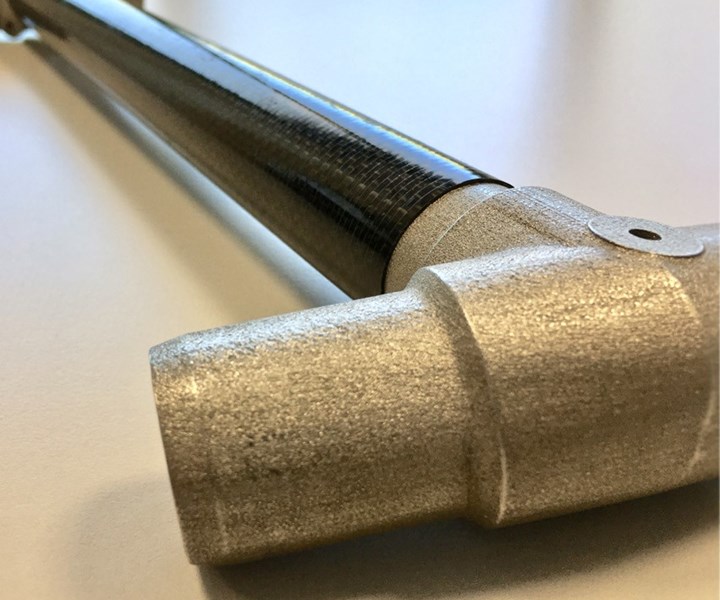

Source | Bercella

Composites specialist Bercella Srl (Varano de’ Melegari, Italy) and additive manufacturing specialist Beamit SpA (Fornovo di Taro, Italy) have announced a strategic partnership to explore joining methods between additively manufactured and carbon fiber-reinforced plastic (CFRP) parts for space, aviation and defense applications.

Both companies provide solutions, ranging from materials development and component qualification, to serial manufacturing, to top OEMs and Tier 1 suppliers. Together, the companies are exploring the potential synergies between the composites and additive manufacturing technologies, with a particular focus on innovative joining methods between AM and CFRP parts.

“We are eager to team-up with Beamit and unlock new potentials for structural optimization,” says Massimo Bercella, CEO of Bercella. “As Italian companies in a territory of excellences, we embrace every challenge determined to succeed. We always find a way, no matter the hassles. And in such a complex time, our common deep roots in the heart of Emilia Romagna will push us to step up driven by a sense of curiosity towards innovation.”

“In Bercella we found a high-professional partner capable to provide leading expertise in composites design and manufacturing for aerospace applications,” says Michele Antolotti, Beamit general manager. “Despite the world economic consequences of the actual pandemic situation, joining forces it’s a strategic way to react and to support high-end companies into their ramp-up of new product development.”

Related Content

-

McLaren develops aerospace-inspired ART method for volume composite super car engineering

Automated rapid tape (ART) technique, already deployed at the MCTC and to be used for future McLaren models, is capable of producing lighter, stiffer and stronger carbon fiber structures with less waste.

-

Co-molding SMC with braided glass fiber demonstrates truck bed potential

Prepreg co-molding compound by IDI Composites International and A&P Technology enables new geometries and levels of strength and resiliency for automotive, mobility.

-

Bladder-assisted compression molding derivative produces complex, autoclave-quality automotive parts

HP Composites’ AirPower technology enables high-rate CFRP roof production with 50% energy savings for the Maserati MC20.

.jpg;width=70;height=70;mode=crop)