Bell, Ingersoll apply LFAM to main rotor blade component production

Collaborative effort using Ingersoll’s MasterPrint LFAM tool and five-axis milling machine completes successful manufacture of 22-foot-long vacuum trim tool in a matter of weeks.

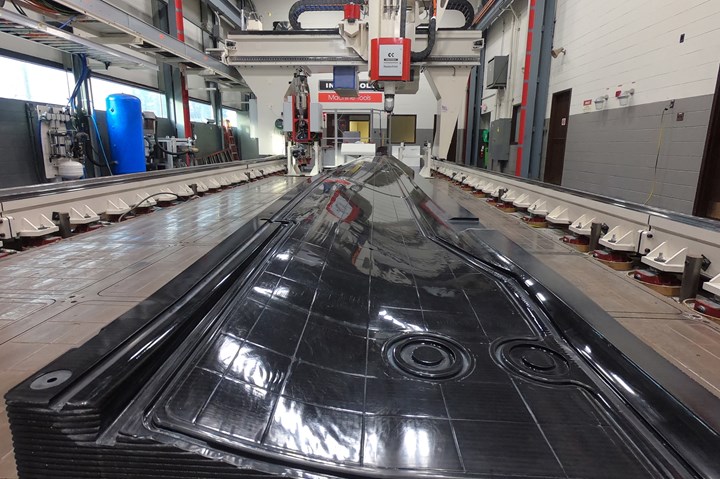

Photo Credit: Ingersoll Machine Tools

Ingersoll Machine Tools, Inc. (Rockford, Ill., U.S.) and (Fort Worth, Texas, U.S.), a Textron Inc. (Providence, R.I., U.S.) company, announced on Feb. 8 the completion of a collaborative effort using Ingersoll’s in-house hybrid, large-format MasterPrint gantry-type 3D printer and five-axis milling machine to successfully manufacture 22-foot-long vacuum trim tool for the production of main rotor blade components.

“We are continuously testing and advancing MasterPrint in our Development Center,” says Chip Storie, CEO at Ingersoll. “Among Ingersoll’s short-term objectives is for MasterPrint to 3D print molds for aerospace that preserve the geometrical properties and tolerances, vacuum integrity and autoclave resilience normally obtained with traditional technology, but with the cost and time reduction only additive manufacturing can offer. The relentless progress our MasterPrint process has made in 2020 has finally made this target attainable.”

According to the companies, this production tooling effort 3D-printed 1,150 pounds of ABS (acrylonitrile butadiene styrene) material with 20% chopped carbon fiber fill. The printing process was completed as a single part in a continuous 75-hour operation. After printing, the mold surfaces and tooling location features were machined to finished dimensions by exchanging the print module for the five-axis milling head, which is changeable on the MasterPrint machine. Machining was completed in one week and the final part achieved full vacuum tightness. According to Ingersoll, its Masterprint machine also makes use of the Siemens 840D CNC control system for controlling both the machining and the 3D printing.

Ingersoll and Bell report that, because the additive and subtractive manufacturing processes were seamlessly co-engineered in the native CAD software format, critical time savings were achieved for this project. While traditional build cycles for a typical mold in aluminum such as this using standard methods is typically 4-5 months, this one was completed in a matter of weeks.

“For many years Bell has used composite materials for manufacturing airframe components, including components produced on an Ingersoll Machine Tools Tape Layer machines. These similar materials are now being used for manufacturing the molds that form the airframe components,” says James Cordell, senior manager, Process Stability, Bell. “Applying this rapid manufacturing equipment will allow Bell to greatly accelerate our development of tooling for many applications within the organization.”

Related Content

-

The next-generation single-aisle: Implications for the composites industry

While the world continues to wait for new single-aisle program announcements from Airbus and Boeing, it’s clear composites will play a role in their fabrication. But in what ways, and what capacity?

-

Development of a composite liquid hydrogen tank for commercial aircraft

Netherlands consortium advances cryogenic composites testing, tank designs and manufacturing including AFP, hybrid winding, welding of tank components and integrated SHM and H2 sensors for demonstrators in 2025.

-

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.