Airbus reveals hydrogen-powered zero-emission engine

Fuel cell engine architecture will be tested onboard Airbus’ ZEROe demonstrator aircraft to determine feasibility of a 2035 entry-into-service.

Photo Credit: Airbus SAS 2022/Herve Gousse

(Toulouse, France) has revealed that it is developing a . The propulsion system is being considered as one of the potential solutions to equip its ZEROe zero-emission passenger aircraft that will enter service by 2035.

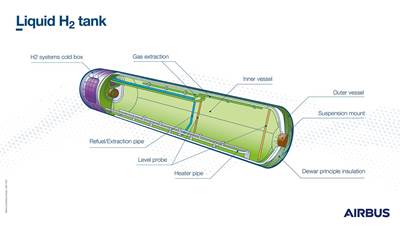

Airbus will start ground and flight testing this fuel cell engine architecture onboard its ZEROe demonstrator aircraft towards the middle of the decade. The A380 MSN1 flight test aircraft for new hydrogen technologies is currently being modified to carry liquid hydrogen (LH2) tanks and their associated distribution systems.

“Fuel cells are a potential solution to help us achieve our zero-emission ambition and we are focused on developing and testing this technology to understand if it is feasible and viable for a 2035 entry-into-service of a zero-emission aircraft,” Glenn Llewellyn, vice president, zero-emission aircraft, Airbus, says. “At scale, and if the technology targets were achieved, fuel cell engines may be able to power a 100-passenger aircraft with a range of approximately 1,000 nautical miles. By continuing to invest in this technology we are giving ourselves additional options that will inform our decisions on the architecture of our future ZEROe aircraft, the development of which we intend to launch in the 2027-2028 timeframe.”

Airbus identified hydrogen as one of the most promising alternatives to power a zero-emission aircraft, because it emits no CO2 when generated from renewable energy, with water being its most significant byproducts.

There are two ways hydrogen can be used as a power source for aircraft propulsion. First via hydrogen combustion in a gas turbine; second, by using fuel cells to convert hydrogen into electricity in order to power a propeller engine. A hydrogen gas turbine can also be coupled with fuel cells instead of batteries in a hybrid-electric architecture.

Hydrogen fuel cells, especially when stacked together, increase their power output, enabling scalability. In addition, an engine powered by hydrogen fuel cells produces zero NOx emissions or contrails, thereby offering additional decarbonization benefits.

Airbus has been exploring the possibilities of fuel cell propulsion systems for aviation for some time. In October 2020, Airbus created Aerostack, a joint venture with ElringKlinger, a company with more than 20 years of experience as both a fuel cell systems and component supplier. In December 2020, Airbus presented its pod-concept which included six removable fuel cell propeller propulsion systems.

Related Content

Infinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MorePlant tour: Collins Aerospace, Riverside, Calif., U.S. and Almere, Netherlands

Composite Tier 1’s long history, acquisition of stamped parts pioneer Dutch Thermoplastic Components, advances roadmap for growth in thermoplastic composite parts.

Read MorePlant tour: Aernnova Composites, Toledo and Illescas, Spain

RTM and ATL/AFP high-rate production sites feature this composites and engineering leader’s continued push for excellence and innovation for future airframes.

Read MoreCombining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

Read MoreRead Next

Airbus launches U.K. ZEDC center for hydrogen technologies

Filton, Bristol location will cover full product capabilities from components up to whole system and cryogenic testing, complementing Airbus’ existing ZEDC facilities for the ZEROe’s 2035 entry-into-service date.

Read MoreWill the Airbus-CFM H2 flight demonstrator use metal or composite tanks?

The Airbus A380 testbed will fly in 2026 with four 100-kilogram liquid hydrogen tanks — metal and composites are being developed via Airbus ZEROe Development Centres — with multiple other programs to develop composite H2 tanks for civil aviation that were begun in 2021.

Read MoreUltrasonic welding for in-space manufacturing of CFRTP

Agile Ultrasonics and NASA trial robotic-compatible carbon fiber-reinforced thermoplastic ultrasonic welding technology for space structures.

Read More