Advanced Composites Training uses augmented reality to deliver composites training

Virtual system delivers live composite technology training courses for a range of industries without the inconvenience of travel.

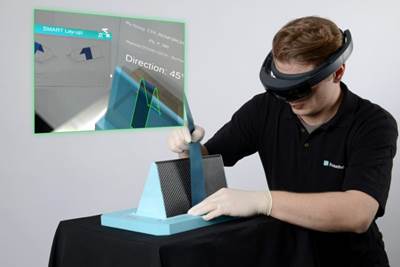

ACT founder Wilson Boynton uses augmented reality to deliver composites training. Photo Credit: ACT

The COVID-19 global pandemic has forced many businesses to find new ways of delivering their goods and services. For Advanced Composites Training (ACT, London, Ontario, Canada), a division of Renaissance Aeronautics Associates (RAA) Inc., that meant developing and launching a new augmented reality system to deliver composites training. Using Microsoft HoloLens2 and software developed by Kognitiv Spark (Brunswick, Canada), ACT is able to offer live courses to students globally.

ACT founder, Wilson Boynton, believes his company is the first to use augmented reality to deliver intensive composites technology training for the aerospace, aviation, automotive, marine and renewable energy industries.

“This is a huge benefit to our clients who are considered essential workers worldwide, but who may not be able to come to London due to travel and quarantine restrictions,” says Boynton. “It also allows us to increase our class sizes, since physical distancing is not a factor.” As the only privately-owned Canadian composites training institute exceeding both Transport Canada and American Federal Aviation Administration standards, ACT works with both civilian and military technicians from more than 39 countries.

ACT offers 17 courses covering all aspects of composites manufacturing and structural repair technologies. According to the company, technicians typically travel to London, Canada for intense on-site training, which combines a mix of theory and hands-on instruction.

However, demand for composites training has remained strong since the beginning of the pandemic, says Boynton, prompting the decision to explore virtual training options. “Augmented reality allows us to project holograms that the instructor sees through the HoloLens,” he says. Students tune in from their laptop or other digital device. “They see exactly what the instructor sees. It’s like having someone looking through your eyes while you are doing the work.”

Reaction to ACT’s augmented reality training has been positive. “Clients are very satisfied,” says Boynton. “Students get the experience of being here, without having to travel.” The launch of augmented reality training is the latest in a number of exciting milestones for ACT.

This February, Boynton enjoyed the thrill of watching NASA’s Perseverance rover land on Mars. Less than two years ago, he was invited to NASA’s Jet Propulsion Laboratory (JPL, Pasadena, Calif., U.S.) to provide training in the composite materials used in its construction. “Composites made the whole thing possible,” he notes.

April 2021, ACT also celebrates 25 years in business. The company plans to celebrate with a 25th Anniversary Virtual Open House on May 11, 2021. “People can take a virtual tour of our facility through the use of the HoloLens and learn more about our training options,” Boynton says.

While augmented reality training will continue to allow technicians from around the world to strengthen their composites knowledge without the inconvenience of travel — long after the global pandemic is over — Boynton believes it will never completely replace the in-class experience.

“Technicians are tactile learners,” he says. “Augmented reality training is an effective way to deliver the vast majority of the knowledge people need to be comfortable working with composites, but it will never completely replace hands-on learning.”

Related Content

Altair, NIAR sign MOU to build aerospace innovation space

Collaboration will expand digital twin adoption, empower aerospace startups and speed up product development and certification processes.

Read MoreHands-on composites training, M&P engineering consulting services

CAMX 2025: Set up in its new facility in Spark, Nevada, Abaris is highlighting its training capabilities, course offerings, and customer consultation and technical assistance.

Read MoreBucci Composites expands automotive production capabilities with facility addition, new high-ton presses

CW Top Shops recipient Bucci Composites shares an update on its facility expansion, automotive composites applications, sustainability, education initiatives and more.

Read MoreAMRC Training Centre introduces composites apprenticeship opportunity

With partners McLaren and Teledyne CML Composites, the Training Center will train new composites technicians in South Yorkshire to build up the future industry workforce.

Read MoreRead Next

Augmented reality system facilitates FRP component preforming

The software makes exact alignment and position of materials directly visible on the component.

Read MoreScaling up, optimizing the flax fiber composite camper

Greenlander’s Sherpa RV cab, which is largely constructed from flax fiber/bio-epoxy sandwich panels, nears commercial production readiness and next-generation scale-up.

Read MoreCutting 100 pounds, certification time for the X-59 nose cone

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.

Read More