Additive manufacturing production epicenter planned for Pittsburgh, Pa.

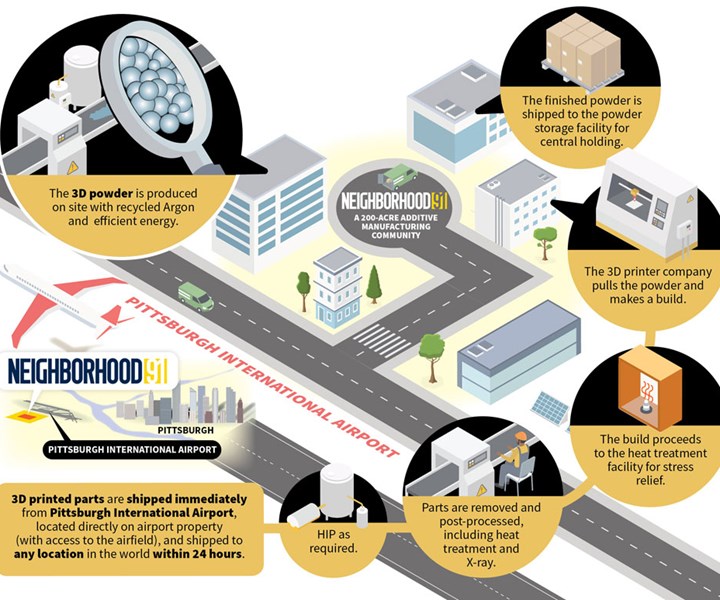

Called “Neighborhood 91,” the project intends to house all elements of the additive manufacturing ecosystem on one campus for ease of production.

Source | Allegheny County Aiport Authority

Pittsburgh International Airport (Pittsburgh, Penn., U.S.) has announced plans to develop what it says is the world’s first production campus dedicated to additive manufacturing and 3D printing.

Called Neighborhood 91 and developed in conjunction with the University of Pittsburgh, the “production neighborhood” concept intends to house all elements of the additive manufacturing supply chain in one concentrated place. This end-to-end ecosystem is said to include:

- powder, parts, post-production, testing and analysis;

- communal powder storage facilities;

- efficiencies in production/post-production and delivery;

- tenants’ clients cost savings from on-demand printing;

- reduced transportation costs;

- airport access, as it will be built adjacent to the airport terminal and runway; and

- supply of argon, helium and other noble gases, which are essential elements of additive manufacturing.

Officials estimated that manufacturing lead times will shrink by 80% and transportation costs will shrink by even more.

The first tenant will be argon gas supplier Arencibia, a leader in recycling gases throughout the aerospace and additive manufacturing supply chain.

The Neighborhood 91 concept is the first development of the 195-acre Pittsburgh Airport Innovation Campus. As part of Neighborhood 91, the airport is planning to construct a second microgrid to power the development to further increase cost savings for tenants. The airport is in the process of developing its first microgrid to power the terminals and airfield.

Construction on Neighborhood 91 will begin next year.

The University of Pittsburgh is a key partner in the development of Neighborhood 91 — both for its research and development and workforce development. The university’s dual strengths of applied additive manufacturing and supply chain research in addition to piloting programs to augment the professional pipeline help fuel the neighborhood concept.

“The Pittsburgh region has always been a world leader in manufacturing,” says Rich Fitzgerald, Allegheny county executive. “Now that industry has evolved into additive manufacturing and 3D printing, and through Neighborhood 91, we have laid the groundwork to become the global epicenter. The neighborhood concept will create enormous efficiencies but just as important is leveraging our region’s universities, which will provide necessary research and development and fuel the workforce to the fill these jobs.”

“Neighborhood 91 brings together the kind of collaborative environment needed to lead in today’s competitive advanced manufacturing economy,” says Patrick Gallagher, University of Pittsburgh chancellor. “It combines the region’s strength in additive manufacturing and advanced materials industries with the intellectual capital of its world-class research universities.”

The name “Neighborhood 91” is based on Pittsburgh’s already existing 90 distinct neighborhoods.

Related Content

-

FACC Academy begins training, onboarding operations

FACC’s newly launched training platform will address skilled aerospace worker shortages head on, offering more than 250 specialized training courses for its entire workforce.

-

Reducing accidental separator inclusion in prepreg layup

ST Engineering MRAS discusses the importance of addressing human factors to reduce separator inclusion in bonded structures.

-

Bucci Composites expands automotive production capabilities with facility addition, new high-ton presses

CW Top Shops recipient Bucci Composites shares an update on its facility expansion, automotive composites applications, sustainability, education initiatives and more.

.jpg;width=70;height=70;mode=crop)