Reversibly crosslinking thermoset-thermoplastic hybrid polymers

Evonik’s new system delivers crosslinked performance of epoxies below 100°C, processing benefits of thermoplastics above 170°C.

Evonik is a specialty chemicals company based in Essen, Germany. It has a strategic innovation unit, called Creavis, which develops new competencies for Evonik by launching Project Houses — cross-organizational ventures with a specific aim and timeline.

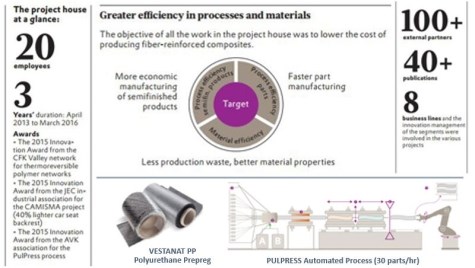

Established in 2013, Evonik’s Composites Project House has developed new materials and system solutions for lightweight construction, mostly aimed at automotive, transportation and energy applications. One example is polyurethane prepreg which offers room-temp storage, 2-3 minute cure in a 180°C compression molding press and a reportedly 35% cost savings vs. RTM. Another development is the PulPress automated process which braids fiber reinforcements around ROHOCELL polymethacrylimide (PMI) foam, injects 2-part resin into the preform and cures in mobile press cells to create 3D sandwich structures up to 1.2 m long on a continuous basis at a reported rate of 30 parts/hr.

SOURCE: “Targeting Greater Efficiency”, pp. 10-11, , published by Evonik.

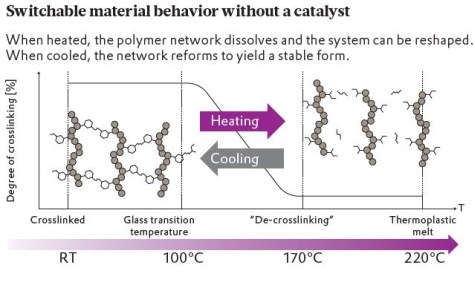

This blog, however, is about the Composites Project House development being launched as “Thermoreversible Crosslinkable Thermoplast-Thermoset Hybrid.” Described as a new class of materials, Evonik’s goal was to combine the mechanical performance of crosslinked thermosets with the fast processing of thermoplastics while resolving the latter’s high-viscosity melt phase which causes fiber impregnation issues.

The solution, developed with the Karlsruhe Institute of Technology (Karlsruhe, Germany), is a special type of Diels-Alder chemical reaction that acts as a thermal switch. With elevated temperature, the crosslinks formed during cure are dissociated for quick reshaping of the composite. Upon cooling, the crosslinks reform, stabilizing the molded shape and ensuring structural properties. The crosslinking that occurs is reversible, and the polymer can reportedly be heated and cooled many times without loss of properties.

SOURCE: “Hybrid Polymers”, pp. 15-16, , published by Evonik.

According to the “Hybrid Polymers” article in issue #54 of Evonik’s innovation magazine Elements, this hybrid system can be applied to a variety of polymers. The first to be commercialized is based on an acrylate copolymer. According to a , this first product is to be released in 2018, and pilot plants in operation since late 2014 at the company’s Marl site have demonstrated that these hybrid polymers save both time and cost in manufacturing composites. Potential customers have already received samples for testing, and a B pillar has been produced with a cycle time of less than 60 seconds.

SOURCE: “Hybrid Polymers”, pp. 15-16, , published by Evonik.

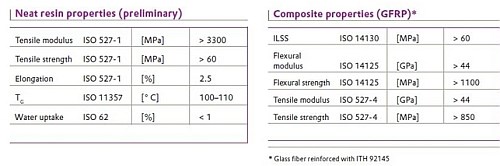

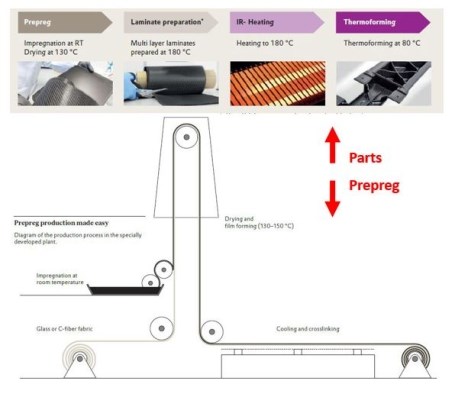

These pilot plants produce glass- and carbon-fiber prepregs where woven and noncrimp fabrics are coated with the hybrid polymer then briefly heated and cooled. These prepregs are not sticky, and thus require no separation or release film. They are also stable at room temperature for more than two years. For parts production, prepreg is cut and stacked and laminates are heated rapidly — e.g. infrared radiation to 180-200°C — to open all crosslinks, after which parts can be quickly molded. No thermal treatment is needed for curing, because the crosslinks reestablish during the cooling step. Thus, cycle times can be very short. Also, any waste produced can be reused or recycled because crosslinking in the hybrid polymer prepreg is reversible.

Properties of the resulting parts, including modulus, tensile strength and water absorption, are on par with epoxies, and thus are superior to thermoplastics like polyamide 6. Performance is consistent up to a service temperature of 100°C.

More recent testing has revealed further benefits. According to Marcel Inhestern, now head of the Thermoreversible Crosslinkable Thermoplast-Thermoset Hybrid project at the Composites Project House, “the material shows excellent alkaline resistance. The chemical resistance is comparable to highly-crosslinked epoxy resins. For example, when stored at pH 13 or higher for several days at higher temperatures the material does not dissolve.”

For more information contact marcel.mi.inhestern@evonik.com

Related Content

Plant tour: Collins Aerospace, Riverside, Calif., U.S. and Almere, Netherlands

Composite Tier 1’s long history, acquisition of stamped parts pioneer Dutch Thermoplastic Components, advances roadmap for growth in thermoplastic composite parts.

Read MorePlant tour: Sekisui Aerospace, Orange City, Iowa, Renton and Sumner, Wash., U.S.

Veteran composites sites use kaizen and innovation culture to expand thermoplastic serial production, 4.0 digitization and new technology for diversified new markets.

Read MoreThermoplastic composites: Cracking the horizontal body panel nut

Versatile sandwich panel technology solves decades-long exterior automotive challenge.

Read MorePlant tour: Airbus, Illescas, Spain

Airbus’ Illescas facility, featuring highly automated composites processes for the A350 lower wing cover and one-piece Section 19 fuselage barrels, works toward production ramp-ups and next-generation aircraft.

Read MoreRead Next

Ultrasonic welding for in-space manufacturing of CFRTP

Agile Ultrasonics and NASA trial robotic-compatible carbon fiber-reinforced thermoplastic ultrasonic welding technology for space structures.

Read MoreScaling up, optimizing the flax fiber composite camper

Greenlander’s Sherpa RV cab, which is largely constructed from flax fiber/bio-epoxy sandwich panels, nears commercial production readiness and next-generation scale-up.

Read MoreNext-gen fan blades: Hybrid twin RTM, printed sensors, laser shock disassembly

MORPHO project demonstrates blade with 20% faster RTM cure cycle, uses AI-based monitoring for improved maintenance/life cycle management and proves laser shock disassembly for recycling.

Read More