Democratizing continuous fiber 3D printing

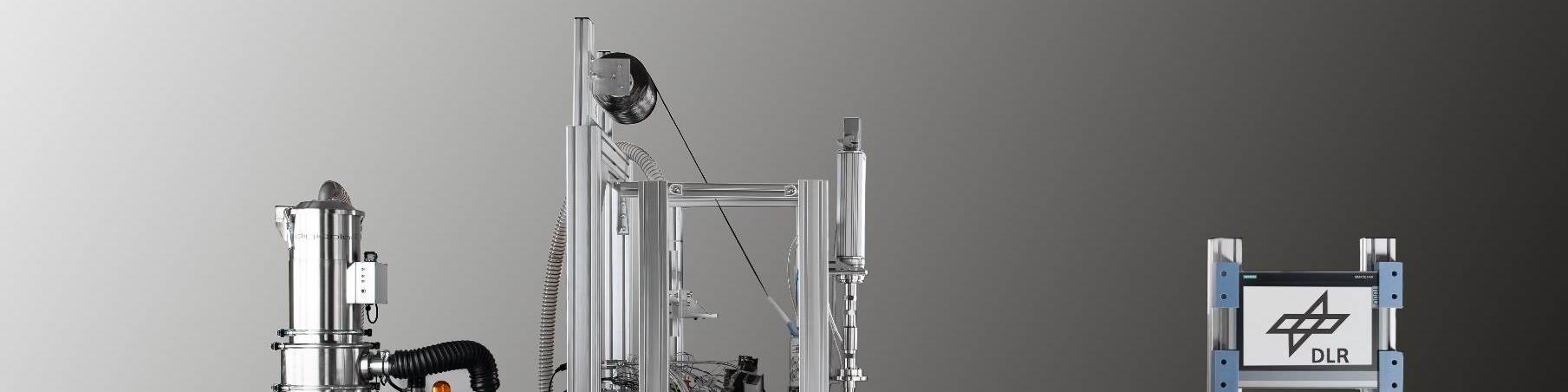

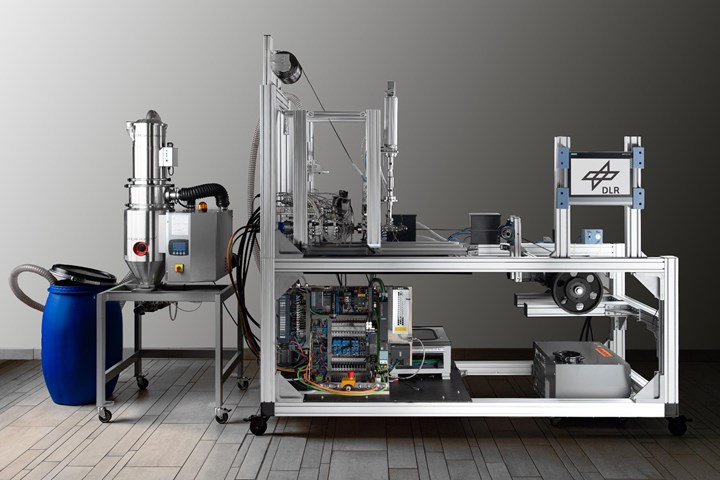

DLR has demonstrated the use of a 19.5-kHz sonotrode (slender silver cylinder at center of system above) to consolidate fibers impregnated with melted thermoplastic from pellets (storage and melting unit at left, above) for low-cost and high-quality continuous fiber-reinforced 3D printer filaments. Photo Credit: DLR,

DLR Institute of Composite Structures and Adaptive Systems (Braunschweig, Germany) is a leading research institution in lightweight construction, pursuing new technologies in four strategic fields: design to certification, digitalization and Industry 4.0, recycling and additive composite structures. CW reported earlier this year on the institute’s EmpowerAX Innovation Lab to accelerate, strengthen and broaden the transfer of additive extrusion to industry for 3D-printed composites. This branch of DLR is also completing an array of R&D projects including simulation of additive extrusion, modification of thermoplastics for improved performance in 3D printing, development of industrial printing hardware and production of printer filaments with continuous fiber.

This last project, titled ENDLOSEFFEKT (“endless effect”), is designed to improve producibility, quality and cost of endless length fiber-reinforced materials. “The availability of pre-impregnated continuous fiber printing filaments is limited,” explains Maik Titze, responsible for additive manufacturing at DLR Institute of Composite Structures and Adaptive Systems in Braunschweig. “This limited availability and variety of usable materials, as well as the material prices, constitute a barrier to application. We wanted to design an impregnation nozzle so that the same equipment used to produce standard, chopped fiber-filled filaments for FDM [fused deposition modeling] could also produce continuous fiber-reinforced filaments. This equipment would be for companies that manufacture 3D printer filaments, with the goal to reduce the cost of 3D printing with continuous fiber-reinforced materials.”

Currently, most continuous fiber-reinforced 3D printer filaments are made by the same companies that sell continuous fiber printing machines, with each material developed and optimized for one particular printing system. These materials tend to be somewhat costly.

“Our idea is to begin with any size of dry fiber, for example 1K carbon fiber tow up to 50K, and then use direct melt impregnation from commodity thermoplastic pellets or granules via extrusion because it is very cost-effective,” says Titze. “You don’t need to produce polymer powder or foils, nor use expensive presses or hundreds of rollers to achieve impregnation of the fiber. So, the processing becomes much more accessible and affordable.”

Instead of presses, belts and rollers, DLR devised a system using ultrasound. “We use a 19.5-kilohertz sonotrode that directs vibration into the melted thermoplastic that surrounds the fiber,” Titze explains. “This introduced sound field propagates through the matrix, creating cyclic pressure changes to compress the matrix and reinforcement at 19,500 times per second, which results in very good impregnation of the reinforcement.”

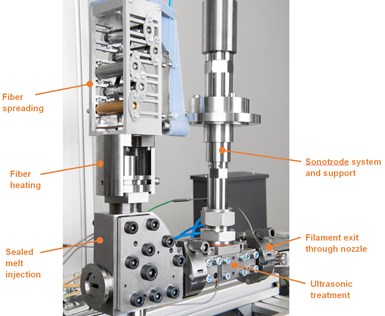

Fig. 1. Ultrasonic-enhanced impregnation

The compact equipment DLR has developed begins with spreading and heating the continuous fiber, which is then impregnated with melted thermoplastic from pellets before making a 90-degree turn to flow through the ultrasonic treatment chamber before exiting through the nozzle, which can be any shape, such as flat or round.

The process path begins with fiber spreading and heating (Fig. 1). This reinforcement is then fed into a sealed chamber into which the melted polymer is injected. As the fiber passes through this chamber, melted resin coats the fiber. “The fiber and polymer then proceed to an ultrasound chamber, which at 80 millimeters in length, is very small and compact,” notes Titze. “The sonotrode-emitted vibrations ensure impregnation of the fiber-reinforced polymer filament, which then exits the nozzle in whatever shape you want. For example, the nozzle can be circular or flat.”

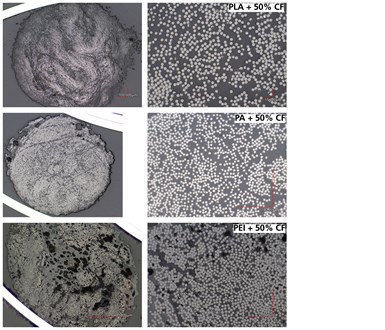

Fig. 2. Improved resin-to-fiber distribution

These micrographs of 12K-24K carbon fiber impregnated with polylactic acid (PLA), polyamide (PA) and polyetherimide (PEI) at 50% fiber volume show good resin-to-fiber distribution and a successful start to DLR’s goal for lower-cost, more widely available continuous fiber materials.

The micrographs in Fig. 2 show 12K-24K (~800 tex) carbon fiber impregnated with polylactic acid (PLA), polyamide (PA) and polyetherimide (PEI) at 50% fiber volume. The fiber volume is adjustable (30-50%) through the design of the die nozzle, says Titze. “We believe up to 60% will be possible. Overall, more work is needed on the process,but we have showed it works with good initial results and at a line speed of 5-20 millimeters/second.” He concedes this is slow, and not economical, but a new equipment design was set to be tested in June, aimed already to reach 3 meters/minute.

“Typically, speeds would be closer to 10 meters/minute,” says Titze. “However, the technology also intends to allow flexible production of new material combinations, so a slightly lower speed could help to make smaller production runs affordable. Of course, further increase in throughput is also a goal.”

The process that DLR has developed is not selective toward one material — any fiber or polymer can be used, says Titze. “This is important as processes continue to hybridize and new materials are needed. Materials for 3D printing must become more competitive, or continuous fiber 3D printing will not have a great future. By using thermoplastic pellets or granules, we can significantly lower the cost and the equipment fits into a small installation space so that even small companies can implement it.”

DLR Institute of Composite Structures and Adaptive Systems started this project in October 2019 and will complete it in January 2022. “Our goal is to further miniaturize the technology and integrate it into a print head,” says Titze. “So, this would be direct impregnation in-line with the printing. Both approaches — offline pre-processing and inline impregnation — will be transferred into industry.” He explains that as a governmental non-profit, DLR will most likely not be “selling” anything and therefore avoid granting exclusive rights. “Our aim is to involve print head and materials suppliers in order to bring down material prices across the board and widen the industrial application of continuous fiber additive manufacturing.”

Related Content

TPI manufactures all-composite Kenworth SuperTruck 2 cab

Class 8 diesel truck, now with a 20% lighter cab, achieves 136% freight efficiency improvement.

Read MoreCIRA qualifies CMC structures for the reusable Space Rider

Italian team designs, builds and tests multiple large, complex thermal protection system structures made from patented ISiComp C/C-SiC ceramic matrix composites.

Read MoreRocket Lab begins installation of large AFP machine for rocket production

The 99-ton AFP machine, custom-designed and built by Electroimpact, is claimed to be the largest of its kind, expecting to save around 150,000 manufacturing hours in the Neutron rocket’s production process.

Read MoreNCC receives investment to support next-gen composite wing

The NCC was awarded a £15.8 million U.K. government grant for HRMCap to de-risk, accelerate innovation in high-rate large aerocomposites structure manufacturing.

Read MoreRead Next

Cutting 100 pounds, certification time for the X-59 nose cone

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.

Read MoreNext-gen fan blades: Hybrid twin RTM, printed sensors, laser shock disassembly

MORPHO project demonstrates blade with 20% faster RTM cure cycle, uses AI-based monitoring for improved maintenance/life cycle management and proves laser shock disassembly for recycling.

Read MoreScaling up, optimizing the flax fiber composite camper

Greenlander’s Sherpa RV cab, which is largely constructed from flax fiber/bio-epoxy sandwich panels, nears commercial production readiness and next-generation scale-up.

Read More