New composite material lowers temp of EV dashboard

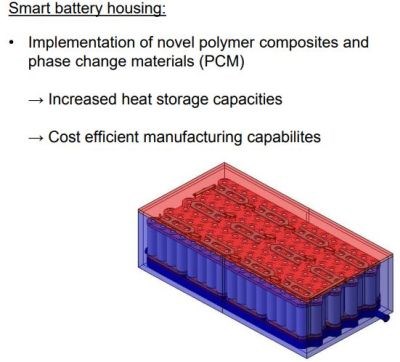

Composites may have new function as phase change materials (PCMs) for managing electric vehicle temperature and range.

New polymer composites may have multiple functions and end-uses in future EVs.

SOURCE: http://xeric.eu/wp-content/uploads/4_Steiner.pdf

Electromobility is gaining momentum in Germany. As reported by Fraunhofer Institute for Structural Durability and System Reliability (Fraunhofer LBF, Darmstadt, Germany) in July, the number of electric vehicles (EVs) almost doubled in 2017 to 93,000. "To further increase sales of electric vehicles, it is not only necessary to optimize performance, such as range, but also to increase occupant comfort. Among other things, this includes sensible and customer-oriented thermal management in the vehicle interior,” says Paul Becker, who heads the research project at Fraunhofer LBF.

The number of electric vehicles in Germany almost doubled in 2017.

A sub-goal of OPTEMUS was to develop novel materials for the EV dashboard to dissipate the heat caused by solar radiation from the dash surface. Fraunhofer LBF solved this by developing a graphite-filled polyethylene (PE) composite material which is integrated with the EV cooling system. The team has achieved a 46% temperature reduction and reduced the energy needed to operate the air conditioning system, which in turn benefits the vehicle range.

OPTEMUS

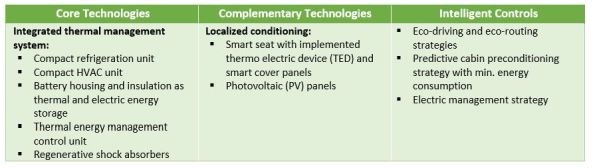

An EU-funded project supported by a large team of companies, OPTEMUS aims to overcome one of the biggest barriers for widespread adoption of electric vehicles (EVs): range limitation due to limited storage capacity of electric batteries. Started in June 2015 and wrapping up next February, OPTEMUS intends to develop a number of innovative core technologies and complementary technologies combined with intelligent controls.

The demonstrator is an A-segment EV (Fiat 500e). This real-life prototype combined with virtual prototyping of the technologies listed below will demonstrate the following objectives:

- Minimum 32% reduction in energy consumption for component cooling and 60% for passenger comfort

- Additional 15% energy reduction available for traction,

- Energy reduction enables an increased driving range in extreme weather conditions > 44 km (38%) in hot ambient and 63 km (70%) in cold ambient conditions.

Composites as Phase Change Materials

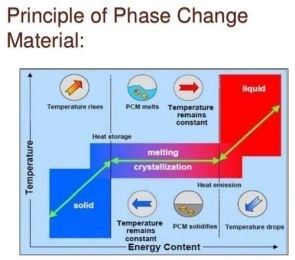

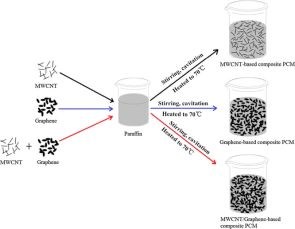

Phase Change Materials (PCMs) have been developed for over a decade for use in buildings, electronics and now cars. PCMs are materials that melt and solidify at certain temperatures with the capability to store or release large amounts of energy during this phase change. Note that solid-gas and liquid-gas PCMs have also been investigated. PCMs may be organic or inorganic compounds, but typically include a conductive filler, which is where graphite comes in. Other PCMs use carbon nanotubes (CNTs).

|

omposites are being developed as Phase Change Materials (PCMs) using graphite, graphene and multi-walled carbon nanotubes (MWCNTs).

SOURCE: (left) and International Journal of Heat and Mass Transfer, Volume 120, May 2018, Pages 33-41 at (right).

Fraunhofer LBF researchers have experimented with different carrier materials and fillers such as boron nitride and graphite. They ended up with a substrate made of polyethylene, a polymer already commonly used in automotive interiors, and graphite as the filler. The graphite reportedly gives the composite a very good thermal conductivity and rapid heat dissipation as well as excellent energy storage.

The working principles for the graphite/PE composite PCM were completed within the "Smart Cover Panel" par of OPTEMUS. To demonstrate the new material’s benefits, researchers incorporated it into the dashboard of the Fiat 500e prototype and cycled it through heating and cooling phases. Cooling was provided by Peltier elements, which are electrothermal transducers, cooled, in turn, by external fans. Energy for the Peltier elements and EV radiator comes from an additional 12-volt battery powered by photovoltaic cells.

Graphite/polypropylene composite PCM installed in dashboard of Fiat 500e prototype vehicle.

SOURCE: Fraunhofer LBF

LBF researchers used the energy released during the phase transition between heating and cooling to switch on the Peltier elements only for a certain period of time. Thus, the fans do not constantly run at maximum power. The cooling system is coupled to the temperature in the material by appropriate regulation. Fraunhofer believes this will extend the life expectancy of the electronic components. The Smart Cover Panel is actually controlled by the sunlight itself, which means that cooling only starts in hot summer days, while the warmth remains in the dashboard during winter.

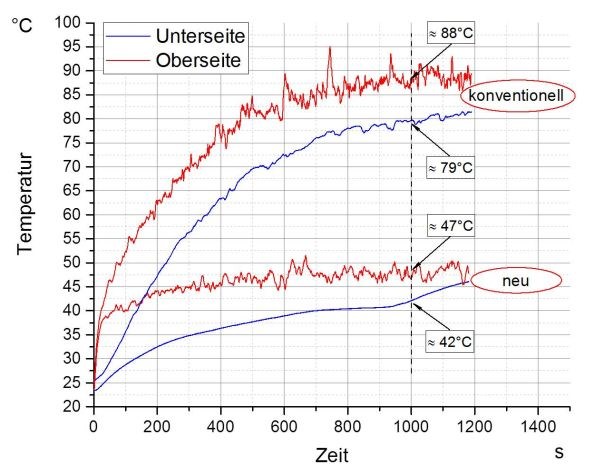

Fraunhofer LBF’s new composite PCM was experimentally compared to polypropylene-talcum compound used in conventional dashboards. After 1000 seconds of exposure to 1200 watts/m2 of radiant power, the temperature difference on the surface of the specimens was roughly 41°C, which corresponds to a 46% reduction in temperature.

Fraunhofer LBF achieved 46% temperature reduction using the new (“neu”) graphite/PE composite PCM in the dashboard vs. the conventional polypropylene-talcum dashboard compound. SOURCE: Fraunhofer LBF.

Related Content

Graphmatech launches Aros polyamide-graphene for Type 4 tanks, secures grant

Combination of polyamide grades and graphene introduces low-permeation solution for upscaling H2 storage, transport applications.

Read MoreNanopoxy, Nione jointly develop nanostructured epoxy resin

Epoxies featuring nanometric niobium pentoxide particles promote toughness, UV radiation resistance and other performance gains.

Read MoreGIM GrapheneFibre commences commercial graphene-enriched carbon fiber production

Saudi Arabia-based company supports Saudi Arabia’s Vision 2030, contributes to full-scale graphene-based composites for a variety of end market applications.

Read MoreCygnet, Viritech recover H2 tank continuous carbon fibers in Ford FCVGen2.0 project

Partner technologies have demonstrated the viability of recycled continuous fibers and the potential for automotive tanks to be recycled at meaningful rates.

Read MoreRead Next

Next-gen fan blades: Hybrid twin RTM, printed sensors, laser shock disassembly

MORPHO project demonstrates blade with 20% faster RTM cure cycle, uses AI-based monitoring for improved maintenance/life cycle management and proves laser shock disassembly for recycling.

Read MoreUltrasonic welding for in-space manufacturing of CFRTP

Agile Ultrasonics and NASA trial robotic-compatible carbon fiber-reinforced thermoplastic ultrasonic welding technology for space structures.

Read MoreScaling up, optimizing the flax fiber composite camper

Greenlander’s Sherpa RV cab, which is largely constructed from flax fiber/bio-epoxy sandwich panels, nears commercial production readiness and next-generation scale-up.

Read More