NASA looking for new core half the areal weight of honeycomb and foam

Two $550K grants to be awarded for new lightweight cores research. Applications due by Dec. 16, 2014.

is one example of the new technology being driven by NASA’s Game Changing Development program. SOURCE: NASA.

The “Ultra-Lightweightcore Materials For Efficient Load-Bearing Composite Sandwich Structures” grant solicitation has been issued as part of NASA’s . The GCD seeks to identify and rapidly mature innovative novel ideas and approaches that have the potential to revolutionize future space missions as well as provide solutions to significant national needs, like energy and manufacturing. CW has reported extensively on the composite cryotank, which is a GCD program.

Other NASA Game Changing Development programs include (from left to right):

parts,

with new climbing legs for zero-gravity mobility,

’s first zero-gravity 3-D printer and

’ low-cost small satellite launch vehicle which uses a methane-fueled aerospike engine and composite cryotanks.

SOURCE: All images sourced from NASA except Firefly sourced from .

GCD issued the “Ultra-lightweight Core Materials for Efficient Load-Bearing Composite Sandwich Structures” solicitation on Oct. 24, 2014. It seeks proposals for the maturation and development of scalable methods to manufacture ultra-lightweight core materials as lower mass alternatives to honeycomb or foam cores in composite sandwich structures. Specifically:

“The development of advanced manufacturing techniques has led to the production of lightweight, hierarchical structures with the potential for use as lower mass alternatives to conventional core components in composite sandwich structures. NASA is interested in scaling up manufacturing processes to produce ultra-lightweight core materials that could be used to produce large-scale composite sandwich structures. The envisioned development effort would demonstrate that materials are a cost-effective and lighter weight alternative to conventional core materials. The overall goal of the Appendix is to develop and demonstrate scalable and cost-effective manufacturing approaches to produce ultra-lightweight core materials both as flat panels and curved structures. The resultant structures will have half or less the areal density of conventional honeycomb cores, while retaining equivalent, or better, mechanical properties.”

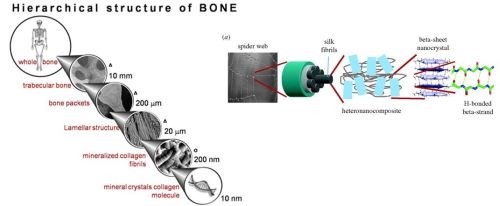

Materials with hierarchical structures include bone and spider silk, which achieve very high strength and/or stiffness with very lightweight. MIT’s recent 3-D printing of core materials — "Ultralight, Ultrastiff Mechanical Metamaterials” — is another example, noting that they have developed microarchitectures into the materials which are then fed into the additive manufacturing machines to create unique macroscale architectures.

The different arrangement of material structures at the various scales within hierarchical materials like bone and spider silk work in concert to perform the diverse mechanical, biological and chemical functions, which enable unique performance advantages.

SOURCE: Surface Engineering, Mawson Institute, University of South Australia (left) and .

This ultralight core initiative is part of a greater Mars mission focus:

Composite sandwich structures are used extensively within the aerospace industry and in other applications where reducing weight while maintaining structural strength is important. A common use for these sorts of composites is the shrouds for launch vehicles and other key technology components that will enable our journey to Mars.

Over the next year, NASA’s Space Technology Mission Directorate (STMD) will continue to seek industry and university partnerships to assure the agency has the capabilities it needs, while helping America maintain its leadership in the technology-driven global economy. These investments will focus on in-space propulsion and advanced high-power solar arrays; robotics and avionics for outer planetary exploration, especially high-reliability and low-mass, deep ice penetration systems; advanced materials, including large composite structures; and space observatory systems, with a focus on advanced optical coating materials.

says NASA expects to make two awards of up to $550,000 each for this first development phase. The Game Changing Development program for STMD is managed by NASA's Langley Research Center in Hampton, Virginia. For the full original posting, .

Related Content

Otto Aviation launches Phantom 3500 business jet with all-composite airframe from Leonardo

Promising 60% less fuel burn and 90% less emissions using SAF, the super-laminar flow design with windowless fuselage will be built using RTM in Florida facility with certification slated for 2030.

Read MoreJEC World 2024 highlights: Thermoplastic composites, CMC and novel processes

CW senior technical editor Ginger Gardiner discusses some of the developments and demonstrators shown at the industry’s largest composites exhibition and conference.

Read MorePlant tour: Teijin Carbon America Inc., Greenwood, S.C., U.S.

In 2018, Teijin broke ground on a facility that is reportedly the largest capacity carbon fiber line currently in existence. The line has been fully functional for nearly two years and has plenty of room for expansion.

Read MoreRevisiting the OceanGate Titan disaster

A year has passed since the tragic loss of the Titan submersible that claimed the lives of five people. What lessons have been learned from the disaster?

Read MoreRead Next

Scaling up, optimizing the flax fiber composite camper

Greenlander’s Sherpa RV cab, which is largely constructed from flax fiber/bio-epoxy sandwich panels, nears commercial production readiness and next-generation scale-up.

Read MoreCutting 100 pounds, certification time for the X-59 nose cone

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.

Read MoreNext-gen fan blades: Hybrid twin RTM, printed sensors, laser shock disassembly

MORPHO project demonstrates blade with 20% faster RTM cure cycle, uses AI-based monitoring for improved maintenance/life cycle management and proves laser shock disassembly for recycling.

Read More