Musings about heat shields

NASA’s Orion capsule employs an ablative material based on the same heat shield coating used for the Apollo missions.

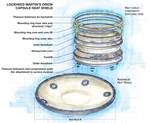

While driving to SPE’s Automotive Composites Conference & Exhibition (ACCE) in Novi, MI, US, I stopped in Wapakoneta, OH to visit the Armstrong Air & Space Museum, as one does. During the drive I had been contemplating heat shield composition of various crew modules because just last week Lockheed Martin (Denver, CO, US) announced it had completed construction on the capsule structure for NASA's Orion Exploration Mission-2 (EM-2) spacecraft and shipped it to Kennedy Space Center in Florida for final assembly.

I knew I’d be traveling by the Armstrong Museum and wanted to stop because some of the technology used for the Apollo capsule was revisited for Orion – specifically Avcoat, an epoxy novolac resin with silica fibers in a fiberglass-phenolic honeycomb matrix. I was hoping there might be a capsule on display, but had to settle for a mockup. There was a Gemini crew module. Similarly, Gemini’s heat shield was made from a paste-like silicone elastomer material which was poured into a fiberglass honeycomb form.

While the Avcoat that is being applied to Orion is pretty much the same material that was applied to Apollo, the method of adhering the material to the craft itself for this mission has changed a bit. Traditionally a fiberglass honeycomb is bonded to the primary structure and the paste-like material is gunned into each cell individually. For the latest Orion capsule, Avcoat blocks are fabricated separately and then bonded to the heat shield base, which is constructed of a titanium truss covered with a carbon fiber composite substrate.

Still, it’s pretty cool to think that Orion has more in common with Apollo than just a similar look; and it’s amazing that a material developed decades ago is still in use today.

Related Content

-

The next-generation single-aisle: Implications for the composites industry

While the world continues to wait for new single-aisle program announcements from Airbus and Boeing, it’s clear composites will play a role in their fabrication. But in what ways, and what capacity?

-

The potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

-

Plant tour: Airbus, Illescas, Spain

Airbus’ Illescas facility, featuring highly automated composites processes for the A350 lower wing cover and one-piece Section 19 fuselage barrels, works toward production ramp-ups and next-generation aircraft.