Cost-effective aerocomposites: Dry fiber AFP and resin infusion

Aurora Flight Sciences and NONA Composites aim to improve toughness, repeatable aerospace quality and affordability for large-scale NASA structures.

Working on Phase II of a Small Business Innovation Research (SBIR) program for NASA Marshall Space Flight Center (Huntsville, AL, US), NONA Composites (Dayton, OH, US) and parent company Cornerstone Research Group (Dayton, OH, US), have subcontracted (Manassas, VA, US) to demonstrate automated fiber placement (AFP) of dry tape and dry tape/prepreg hybrids for vacuum infusion processing.

“The combination of NONA’s room temperature infusion and flexible curing epoxy resins with dry tape reinforcements allows for lower cost raw materials and curing compared to prepreg,” says NONA Composites president Ben Dietsch. He adds that automated fiber placement imparts significant control on the fiber preform prior to infusion. “The infusion preform has traditionally been a key source of part variability,” notes Dietsch. AFP also automates fabrication of large-scale structures. “Our goal is to demonstrate the combination of these technologies, and their ability to cut costs and improve repeatability in large out of autoclave composites.”

|

Aurora Flight Sciences will use this 7-axis Electroimpact AFP) machine in its Columbus, Mississippi facility to build preforms from dry fiber tape and dry tape/prepreg hybrids which will be infused with NONA Composites room-temp cure epoxy resin.

SOURCE: Aurora Flight Sciences.

The overall goal of the program is to tackle some of the technical and operational hurdles with acceptance of infusion processing for aerospace parts, namely, improving part toughness of a room-temperature infused structure and demonstrating affordable, repeatable manufacturing at the large geometric scale required by NASA. “Toughness is a limiting factor in the design of aerospace structures,” explains Dietsch. “Traditionally, it has been more difficult to achieve the same toughness with resin-infused dry preforms as is possible with toughened prepregs cured in an autoclave.” NONA Composites and CRG, however, are pursuing two paths to rectify this. The first is through resin chemistry, the results of which NONA Composites will present at the (Sep. 26-29, Anaheim, CA, US). The second route is using thermoplastic veil materials in the dry fiber AFP, which not only adds toughness but also prevents material slippage during laydown. I wrote about this in my 2014 article on the MS-21’s resin-infused wings:

|

AeroComposit’s R&D lab tested many detail and element samples to help define this balance. It also evaluated many materials. “We tested materials with an open structure to help resin flow, as well as more closed materials, which relied on other means for permeability, such as ensured clearance between tapes,” says Gaidansky. Tapes, rather than hand-layed pieces of noncrimp fabric, were used because they could produce precision details with consistent speed through the use of an automated dry stack layup process." “Dry material, by definition, is not impregnated with any sticky resin, and thus easily moves from the position in which it is layed down,” explains MTorres sales director Juan Solano. “Our challenge was to somehow make the material stay in place to enable accurate machine-automated fiber location and ensure that this does not change after the fiber has been layed.” The solution? A very thin, lightweight thermoplastic veil functions as a binder during automated dry fiber placement. During layup the veil provides enough tack to affix the fiber. … The veil also provides a grid structure that increases resin flow and contributes to the desired compression-after-impact and interlaminar-shear-strength properties. |

For more details, read the full article, and also “Dry fiber placement: Surpassing limits” and “FACC: Aerospace infusion pioneer”

In order to make headway in demonstrating affordable and repeatable large structures, NONA Composites needed to partner with a parts manufacturer, and preferably one that was interested in working to develop new technology. “We’re excited to work with Aurora Flight Sciences,” says Dietsch. “Not only are they well-versed in the demands of aerospace composite structures production and out-of-autoclave processing, but they also have a lot of experience with SBIR development work and are very forward-thinking.” He adds that Aurora’s AFP equipment is also very similar to that at NASA Marshall Space Flight Center, and the two facilities are within easy driving distance of each other. “So we know anything we learn from the work at Aurora, NASA could implement easily,” says Dietsch.

NASA will reportedly build the biggest composite rocket parts ever made using this robotic system, part of the Composites Technology Center at NASA’s Marshall Space Flight Center in Huntsville, Alabama. SOURCE: NASA.

Aurora Flight Sciences will be performing this SBIR work in their Columbus, Mississippi facility, which houses a state-of-the-art 7-axis high rail gantry Electroimpact AFP machine with heads capable of laying half-inch and quarter-inch wide slit tape. Dr. Konstantine Fetfatsidis, director of advanced composites programs at Aurora, says his company is looking forward to this development work with NONA and CRG, “and to demonstrate a relatively new approach to cost-competitiveness in composites fabrication which leverages our investments in this area.”

Part of the collaboration will involve benchmarking the new technology against existing Aurora AFP production efforts. As projected performance and cost benefits are realized, the team will also be reaching out to potential OEM partners for further collaboration. These Phase II Enhancement efforts can be cost-shared by the NASA SBIR program. Ben Dietsch and Konstantine Fetfatsidis will both be participating in a panel session on out-of–autoclave technology at the upcoming SAMPE Conference and Exhibition (May 23-27, Long Beach, CA, US) and will discuss the technology in this development program during that event.

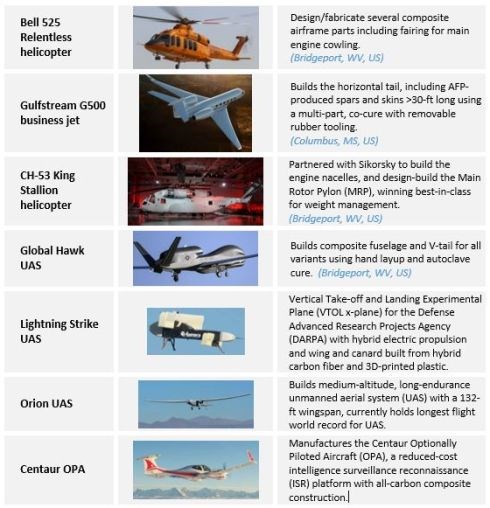

Below is a brief background on Aurora Flight Sciences. To me it shows not only that Aurora is a very interesting player in composite aerostructures but also a good choice for NONA Composites’ partner in this OOA AFP development work.

Aurora Flight Sciences

A Tier 1 supplier of composite structures for both the commercial and military aerospace markets, Aurora Flight Sciences is also an OEM. It provides a full range of services as a fabricator, including conceptual design development, testing and first part qualification/certification and also delivers complete assemblies with integrated subsystems such as pneumatics, fuel and air lines, and avionics. Aurora’s Aerostructures group specializes in complex design, build-to-print and rapid prototyping of airframes from both advanced composites and metals.

Headquartered in Manassas, VA, Aurora operates production plants in Bridgeport, West Virginia and Columbus, Mississippi. The company also has a Research and Development Center in Cambridge, Massachusetts, and a recently opened office in Mountain View, California.

Current programs include:

Aurora was also awarded a variety of Small Business Innovation Research (SBIR) grants in 2015, including several directly related to composites:

- Automated Manufacture of Damage Detecting, Self-Healing Composite Cryogenic Pressure Vessels

- Benefit Analysis of Hybrid CNT/CFRP Composites in Future Aircraft Structures

- In-situ Sensing for Multi-Functional Structures.

Related Content

Infinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

Read MoreRevisiting the OceanGate Titan disaster

A year has passed since the tragic loss of the Titan submersible that claimed the lives of five people. What lessons have been learned from the disaster?

Read MoreCarbon fiber composite pallet revolutionizes freight industry

LOG Point Pallet fuses advanced materials with innovative design and manufacturing to improve supply chains worldwide.

Read MoreThe potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

Read MoreRead Next

Scaling up, optimizing the flax fiber composite camper

Greenlander’s Sherpa RV cab, which is largely constructed from flax fiber/bio-epoxy sandwich panels, nears commercial production readiness and next-generation scale-up.

Read MoreNext-gen fan blades: Hybrid twin RTM, printed sensors, laser shock disassembly

MORPHO project demonstrates blade with 20% faster RTM cure cycle, uses AI-based monitoring for improved maintenance/life cycle management and proves laser shock disassembly for recycling.

Read MoreUltrasonic welding for in-space manufacturing of CFRTP

Agile Ultrasonics and NASA trial robotic-compatible carbon fiber-reinforced thermoplastic ultrasonic welding technology for space structures.

Read More