Concrete composite that heals itself

The concept of self-healing materials isn’t new, however, there’s been a renewed interest in the technology due to the maintenance needs of deteriorating infrastructures.

Mustafa Sahmaran, professor at Gazi University, tests the performance of healed ECC specimen under mechanical loading. Image courtesy of the American Concrete Institute.

It’s no secret the human body can do some amazing things. If you cut your hand, it will heal automatically. Right after you fall and skin your knees, your body is already working to repair the wound. Our bodies are designed to heal from small wounds on its own. And it turns out, we share that characteristic with concrete. The world’s most popular building material can self-heal its own small wounds (aka cracks) as an intrinsic characteristic.

However, unlike the human body, cracks do not heal easily in conventional concrete due to its brittle nature. And this is where Engineered Cementitious Composites (ECC) look to come in. ECCs are based on an advanced material technology first proposed by Victor C. Li from University of Michigan in Ann Arbor.

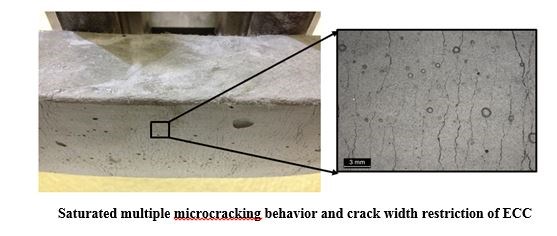

Unlike the conventional concrete materials preferred in most field practices, ECC, which has reinforcing microfibers smaller than human hair, is relatively ductile in tension. Ductility is a direct result of strain-hardening response due to the formation of multiple closely spaced microcracks with average widths of less than 100 micrometers. Even under excessive loading conditions, crack widths reportedly remain constant.

“Having cracks with widths at micrometer levels allows us to add special attributes such as self-healing to ECC material,” said Mustafa Sahmaran, professor of civil engineering and director of the Advanced Infrastructure Materials Research Laboratory at Gazi University, Ankara, Turkey.

The concept of self-healing materials isn’t new, however, there’s been a recent interest in the technology of these materials due to the deteriorating infrastructures found around the world.

Sahmaran says that the process of self-healing in ECC materials is quite straightforward. Cracks heal themselves with the help of two main mechanisms: ongoing hydration reactions of anhydrous cementitious materials resulting in further calcium-silicate-hydrate gels and calcium carbonate precipitation. What is needed for these two reactions to take place is abundantly available for structures located anywhere in the world: water and air.

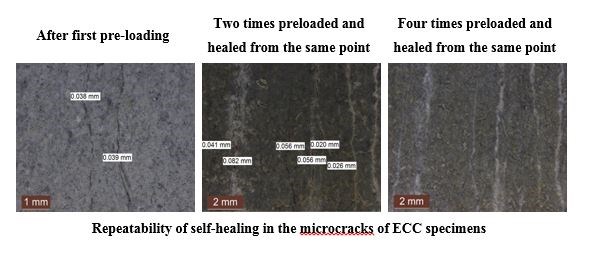

“Despite the effectiveness of self-healing in ECCs with micron-size cracks, some critics question the ‘robustness’ of the mechanism,” he said. “One such robustness criterion is the ‘repeatability,’ or multiple reoccurrence of crack closure. The other criterion is the ‘pervasiveness, meaning that the mechanism should take place all over the structural element rather than being restricted to certain areas.”

Sahmaran and his lab team, in cooperation with Mohamed Lachemi from Ryerson University in Canada sought an answer to the question of robustness of the self-healing mechanism in ECCs. The verdict? They believe they can prove the relatively high robustness of self-healing in ECC.

“Even after six repetitive pre-cracking occurrences from the exact same place, each one almost causing specimen failure, ECC material can recover by 85% depending on the test method utilized in the evaluation of self-healing rate,” said Gurkan Yildirim, research assistant and Ph.D. candidate in civil engineering at Gazi University. “Self-healing rates recorded from different sections of specimens also confirm that results are very close to each other, meaning that the mechanism is rather pervasive. On top of that, ECC material does not sacrifice the intrinsic tight microcracking behavior, so that after the application of pre-cracking from the same place up to nine repetitive times, maximum crack width is restricted to a 190 micrometer level, which also leads to superior durability characteristics, even under harsh environmental conditions.”

The researchers say that with its inherent tight microcracking and self-healing behavior, ECC could become the material solution to many mechanical and durability property challenges and can help prolong infrastructure functionalization.

The team's research appeared in a paper entitled “Repeatability and Pervasiveness of Self-Healing in Engineered Cementitious Composites,” which was published by the ACI Materials Journal.

Related Content

Plant tour: BeSpline/Addcomp, Sherbrooke, QC, Canada

Composites automation specialist increases access to next-gen technologies, including novel AFP systems and unique 3D parts using adaptive molds.

Read MoreSwedish parking garage to incorporate decommissioned wind blades

Architect Jonas Lloyd is working with Vattenfall to design the multistory building with a wind blade façade, targeting eco-friendly buildings and creative ways to remove blades from landfills.

Read MoreBio-based, fire-resistant composites become mainstream

Projects use Duplicor prepreg panels with highest Euroclass B fire performance without fire retardants for reduced weight, CO2 footprint in sustainable yet affordable roofs, high-rise façades and modular housing.

Read MoreU.S. grant is awarded for patented SIP composites formwork system

ConTech stay-in-place (SIP) technology, made from recycled composite materials, replaces the use of reinforcing steel in the construction of flat, elevated concrete surfaces.

Read MoreRead Next

Ceramic matrix composites: Faster, cheaper, higher temperature

New players proliferate, increasing CMC materials and manufacturing capacity, novel processes and automation to meet demand for higher part volumes and performance.

Read MoreScaling up, optimizing the flax fiber composite camper

Greenlander’s Sherpa RV cab, which is largely constructed from flax fiber/bio-epoxy sandwich panels, nears commercial production readiness and next-generation scale-up.

Read MoreNext-gen fan blades: Hybrid twin RTM, printed sensors, laser shock disassembly

MORPHO project demonstrates blade with 20% faster RTM cure cycle, uses AI-based monitoring for improved maintenance/life cycle management and proves laser shock disassembly for recycling.

Read More