Big composite container protects vital satellite

Before they experience the vibrations of launch and the rigors of the space environment, satellites first have to make it to the launch pad. Pagnotta Engineering Inc. (PEI, Exton, PA, US) was called upon by Orbital ATK (Dulles, VA, US) to design a shipping box to protect Orbital ATK’s GEOStar-3 geosynchronous satellite bus structure, during shipment.

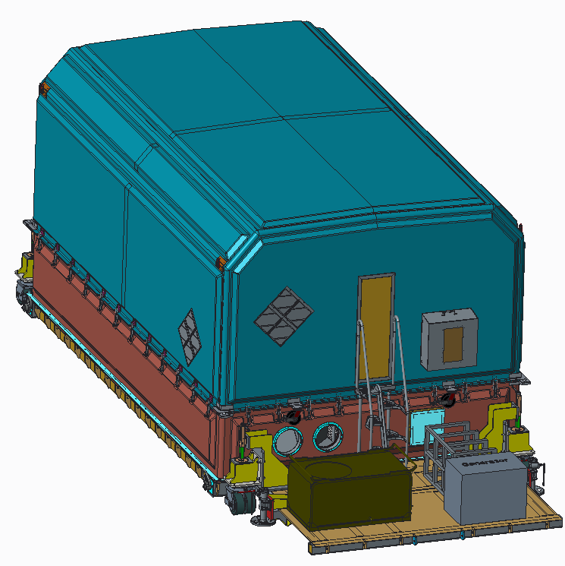

This composite shipping container designed by PEI and built by Ershigs protects fragile satellites during shipment to launch locations.

Satellites are built to painstaking specifications using specialized materials, and represent huge investments. Before they experience the vibrations of launch and the rigors of the space environment, they first have to make it to the launch pad, intact. A company called Pagnotta Engineering Inc. (PEI, Exton, PA, US) was called upon by Orbital ATK (Dulles, VA, US) to design a massive shipping box to protect Orbital ATK’s GEOStar-3 geosynchronous satellite bus structure, during shipment from Dulles to launch locations such as French Guiana, for example.

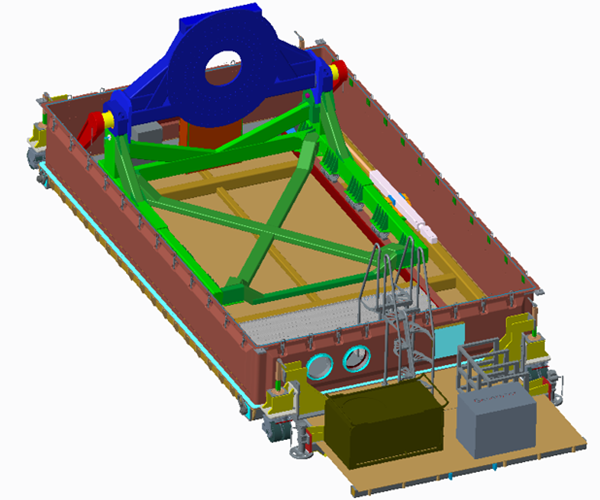

This inside view of the container, with upper lid removed, shows the lower, immovable lid and the inner steel frame, with the support frame for the satellite.

The task was not trivial: the spacecraft can weigh up to 3,136 kg and has dimensions of 3.9m (max) by 2.1m x 2.3m. The container had to be able to fit through all Orbital ATK facility access doors, be strong and reliable with stable lifting provisions, be compatible with truck and rail logistics and most important, fit inside an Antonov 124-100 cargo aircraft. PEI developed a multi-material solution, including a welded steel base frame and a two-part composite lid, upper and lower, says PEI’s vice president John Callahan: “We decided on a two-section composite lid to reduce the overhead lifting requirements to clear the spacecraft, minimize the connections to auxiliary equipment and to simplify the interface to the base frame.” PEI developed the design in Pro/E CREO (Needham, MA, US) CAD software, and used NX/NASTRAN and FEMAP software from Siemens PLM Software Inc. (Plano, TX, US) for finite element analysis (FEA) to provide structural verification and that transport loading scenarios wouldn’t allow stresses above allowable limits.

The container was fabricated by Ershigs. The lower lid is shown here, with the upper lid panels being assembled with the help of a metal jig.

Composites were the right choice for the lid, beyond low weight, explains Callahan. They offered an airtight solution, with high thermal R-value and minimal joints, one that was weatherproof, strong and durable. Plus, the lids could be made on simple tooling to help keep costs low. The composite solution was a sandwich panel construction with skins of E-glass chopped strand mat, woven roving and knitted biaxial fabric, supplied by Owens Corning (Toledo, OH, US), Vectorply Composites (Phenix City, AL, US) and ValuTex Reinforcements (Washington Court House, OH, US), over a BALTEK (Sins, Switzerland) SB 50 balsa core. Resin was a Derakane Class 1 fire retardant vinyl ester from Ashland (Columbus, OH, US). The composite lids, upper and lower, were fabricated by Ershigs (Bellingham, WA, US).

The lower, immovable lid, at 7.7m long by 4.7m wide by 1.08m high, was connected directly to the base frame. The matching upper, 2.8m high lid attaches to the lower with multiple quick-release latches, and has casters mounted along its lower edge so it can be moved around when detached. A door in the upper lid allows access to the interior, and a lot of ancillary equipment, including an air conditioning unit, generator, electrical and nitrogen gas connections, gets attached to the metal base frame; multiple access panels and duct holes in the lower lid allow access for those systems to the interior. Inside, a large spacecraft turn-over and handling fixture and frame hold the satellite in place.

The shipping container can fit inside an Antonov transport aircraft.

So far, the shipping container has been used three times to successfully transport spacecraft. CW plans on a more detailed look at the design in an upcoming issue of CW magazine.

Related Content

Carbon fiber/flax landing gear achieves 54% weight reduction via tailored layup optimization

Fuko’s Biogear showcases how strategic composite material distribution and natural fiber damping properties can lightweight and enhance critical aerospace structure performance.

Read MoreCarbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.

Read MoreProving thermoplastic composites match carbon fiber/epoxy performance in road bikes

CDCQ, LxSim, Addcomp and Argon 18 collaborate to optimize a carbon fiber/PA6 bike seat post, democratizing AFP and demonstrating materials and process for future designs and production.

Read MoreCutting 100 pounds, certification time for the X-59 nose cone

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.

Read MoreRead Next

Ultrasonic welding for in-space manufacturing of CFRTP

Agile Ultrasonics and NASA trial robotic-compatible carbon fiber-reinforced thermoplastic ultrasonic welding technology for space structures.

Read MoreNext-gen fan blades: Hybrid twin RTM, printed sensors, laser shock disassembly

MORPHO project demonstrates blade with 20% faster RTM cure cycle, uses AI-based monitoring for improved maintenance/life cycle management and proves laser shock disassembly for recycling.

Read MoreScaling up, optimizing the flax fiber composite camper

Greenlander’s Sherpa RV cab, which is largely constructed from flax fiber/bio-epoxy sandwich panels, nears commercial production readiness and next-generation scale-up.

Read More