Another win on a carbon composite SUP - Update

CW’s June 2017 Focus on Design story was about the design and creation of a custom carbon composite racing SUP or stand-up paddleboard (that led to a similar production SUP for consumers) for paddle athlete Travis Grant. Grant just won this year’s Molokai to Oahu race, on a new carbon fiber SUP, and set a world record.

Travis Grant crosses the finish line of the 2017 M2O race in Hawaii on an all-carbon composite SUP board from NSP and Cobra International. Photo from the Honolulu Star Advertiser, photographer Bruce Asato.

I hope you all had a chance to read my June 2017 Focus on Design story about the design and creation of a custom carbon composite racing SUP or stand-up paddleboard (that led to a similar production SUP for consumers) for paddle athlete Travis Grant, winner of the 2015 (and earlier 2013) Molokai 2 Oahu Ocean Race across the Ka’iwi Channel, a distance of 52 km. Because the focus of that story was on the composite board and how it came to be, I never got the chance to interview Grant, although I scoured media reports and his Facebook page, where he talked about that win.

Grant recently contacted me, and told me that he is the winner of the 2017 edition of M2O race, held on July 30, again on a Cobra International Co. Ltd. (Chonburi, Thailand) – manufactured, NSP (Singapore)-designed Molokai custom SUP. And, he set a new record time for the event. I reached out to Trent Pedersen, who is a technical consultant to NSP and the Aroona Group, the distributor of NSP boards in Australia and New Zealand, and involved in the realization of Grant’s 2017 board, for some details.

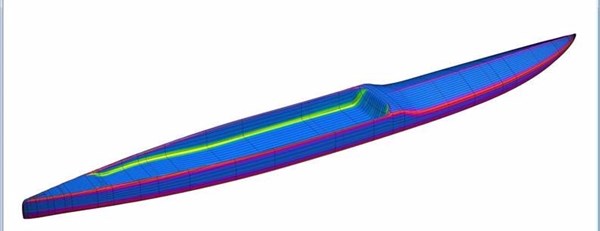

“The latest design Travis used is quite different to the one you featured [in the FOD],” says Pedersen. “As you can see from the CAD screen shot, the main difference is overall the board is thicker, rails are higher, and we recessed the deck a lot, to make a ‘dugout’ style board. The reason was to increase stability, and reduce drag in the rough conditions by not having the water ‘suck’ over onto the deck of the board. The nose area is thicker with a really defined V-shape so the water releases, and at the same time we designed a high cowling to stop water entering the cockpit.” He adds that the board has four drain holes that allow water to drain, designed so that the holes themselves don’t cause drag.

CAD screen shot of the 2017 dugout-style SUP, from NSP

Pedersen adds that because the dugout design has a much more pronounced and recessed standing area, this increased the overall surface area of the board. That meant the old (2015) layup would be too heavy, and not give sufficient strength.

“The thickness of the standing area was reduced by approximately 40% so we had to maintain the structural integrity in this area. The EPS core density stayed at 15.5 kg/m2, but we changed the material layup. For the bottom, the previous board used a combination of ±45° biaxial carbon and fiberglass, which meant 250gsm of fiber. For the new design we opted for 100% carbon and combined a +30/-30 degree biax and a UD carbon. The resulting total reinforcement weight ended up 180 gsm, so it was lighter, 100% carbon, and the orientation of fibers gave more stiffness,” explains Pedersen.

For the deck, the 2015 board was made with a combination of plain weave carbon and glass, with about 260 gsm areal weight. “For the new design we opted for 100% carbon using the same materials as the bottom. The 100% carbon layup allowed us to reduce the density and thickness of the PVC material in the standing area, further reducing weight. We still used some light fiberglass in the PVC sandwich.” Further, the team opted to replace the 20cm wide PVC/fiberglass stringer at the nose area with small-tow carbon fiber T-stringers, one near each rail and one down the center line: “Essentially we cut 2.5 cm deep into the board and laminated a 10cm wide piece of carbon creating a T shape using the carbon fiber, for more stiffness,” explains Pedersen. Board rails had an extra layer of carbon added, for the same double wrap like the earlier board, and glass strips were added in high impact areas on top of the rail.

Travis Grant at the finish (photo from the Honolulu Star Advertiser, photographer Bruce Asato).

Grant finished in 3 hours, 59 minutes and 52 seconds, setting a new world record in the men’s unlimited stand-up paddleboard division, and breaking the 4-hour time barrier, in a close contest with 2nd-place finisher Connor Baxter. Grant was quoted on the official race press release as saying “I never thought SUP could not break 4 hours…It was hard. I hope this record stands for longer than a year.”

There are a lot of videos and photos if you’re interested, including this one from NSP: . Try this link for a 6-minute short movie celebrating the 20-year history of the race here: . Grant appears at the very end of the video, as he crosses the finish line. The official Web site of the event is here: . Start paddling!

Related Content

Bladder-assisted compression molding derivative produces complex, autoclave-quality automotive parts

HP Composites’ AirPower technology enables high-rate CFRP roof production with 50% energy savings for the Maserati MC20.

Read MoreComposites end markets: New space (2025)

Composite materials — with their unmatched strength-to-weight ratio, durability in extreme environments and design versatility — are at the heart of innovations in satellites, propulsion systems and lunar exploration vehicles, propelling the space economy toward a $1.8 trillion future.

Read MoreCutting 100 pounds, certification time for the X-59 nose cone

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.

Read MoreCo-molding SMC with braided glass fiber demonstrates truck bed potential

Prepreg co-molding compound by IDI Composites International and A&P Technology enables new geometries and levels of strength and resiliency for automotive, mobility.

Read MoreRead Next

Next-gen fan blades: Hybrid twin RTM, printed sensors, laser shock disassembly

MORPHO project demonstrates blade with 20% faster RTM cure cycle, uses AI-based monitoring for improved maintenance/life cycle management and proves laser shock disassembly for recycling.

Read MoreCeramic matrix composites: Faster, cheaper, higher temperature

New players proliferate, increasing CMC materials and manufacturing capacity, novel processes and automation to meet demand for higher part volumes and performance.

Read MoreScaling up, optimizing the flax fiber composite camper

Greenlander’s Sherpa RV cab, which is largely constructed from flax fiber/bio-epoxy sandwich panels, nears commercial production readiness and next-generation scale-up.

Read More