Aerospace, construction CAMX Awards winners

Representing both ends of the composites industry spectrum, the inaugural CAMX Awards go to Epitome Foundation Walls and the NASA-Boeing all-composite cryotank.

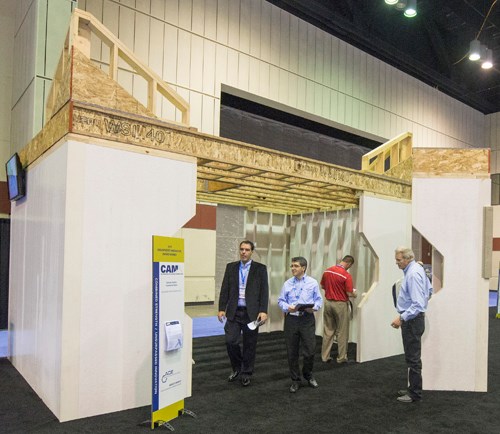

Composite Panel Systems LLC's Epitome Quality Foundation Walls was one of two CAMX Awards winners, in the category of Unsurpassed Innovation.

The inaugural CAMX 2014 (Oct. 13-16, Orlando, Fla.) introduced to the composites industry a new awards program, called CAMX Awards. Twelve finalists competed for two CAMX Awards, one to recognize collaboration and teamwork in a composite application, and the other to recognize innovation that promises to provide substantial market impact.

On Tuesday, Oct. 14, during the CAMX General Session, Ashland announced the winners of the 2014 CAMX Awards, which, like the show, represented the diversity of the composites industry itself. The Combined Strength Award was given to the NASA-Boeing Composite Cryotank Technologies & Demonstration Team, submitted by NASA Glenn Research. The Unsurpassed Innovation Award was given to the Epitome Quality Foundation Walls, submitted by Composite Panel Systems LLC.

NASA and Boeing worked together to develop an all-composite cryogenic fuel tank for space launch vehicles, which won the CAMX Combined Strength Award. This sub-scale version of the tank was on exhibit at CAMX. The full-size tank is 8.4m in diameter.

NASA worked with Boeing to design, fabricate and test an all-composite cryogenic fuel tank for space launch vehicles. The tank achieved a 30 percent weight savings and 25 percent cost savings, allowing insertion of higher mass payloads to low-Earth orbit and beyond. At the current space launch system configuration of 8.4m/27.6 ft diameter, the composite cryotank could warrant as much as 1,400 kg/3,806 lb of added payload.

John Vickers, NASA program manager for the Composite Cryotank Technologies and Demonstration Team, receiving the CAMX Award.

Receiving the Combined Strength Award was John Vickers, NASA program manager for the Composite Cryotank Technologies & Demonstration Team. “A lot of people worked very hard between government and industry and Boeing and NASA to make this project work,” he told the crowd of more than 1,000 who attended the CAMX General Session and Keynote Tuesday morning. He noted that the tank went a long way toward proving composite capabilities in space launch applications. “We threw a lot at these tanks during testing, and they stood up.”

Glenn Schiffmann, managing member of Composite Panel Systems LLC, receiving the CAMX Award.

Receiving the Unsurpassed Innovation Award was Glenn Schiffmann, managing member of Composite Panel Systems LLC (Eagle River, Wis.). He told the audience that it was two years ago, at the National Homebuilders Show in Orlando, that he first hatched the idea of a composite sandwich panel system designed to replace traditional concrete in residential home foundations. Working with the close support of resin manufacturer Ashland, Schiffmann says his panel system provides easy and fast installation which can be performed by typical work crew, without the time and effort required to pour a concrete foundation. Further, it provides R-16.5 insulation value, integrated stud cavities for mechanicals and inherent damp-proofing. Schiffmann says reception in the building and construction industry to the Epitome Quality Foundation Walls system has been positive so far. He’s working with Ashland and other suppliers to increase manufacturing efficiencies and drive down the cost further and make it more cost-competitive with concrete. That’s within reach, he believes.

Related Content

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreDevelopment of a composite liquid hydrogen tank for commercial aircraft

Netherlands consortium advances cryogenic composites testing, tank designs and manufacturing including AFP, hybrid winding, welding of tank components and integrated SHM and H2 sensors for demonstrators in 2025.

Read MorePlant tour: Aernnova Composites, Toledo and Illescas, Spain

RTM and ATL/AFP high-rate production sites feature this composites and engineering leader’s continued push for excellence and innovation for future airframes.

Read MorePlant tour: Airbus, Illescas, Spain

Airbus’ Illescas facility, featuring highly automated composites processes for the A350 lower wing cover and one-piece Section 19 fuselage barrels, works toward production ramp-ups and next-generation aircraft.

Read MoreRead Next

Cutting 100 pounds, certification time for the X-59 nose cone

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.

Read MoreScaling up, optimizing the flax fiber composite camper

Greenlander’s Sherpa RV cab, which is largely constructed from flax fiber/bio-epoxy sandwich panels, nears commercial production readiness and next-generation scale-up.

Read MoreCeramic matrix composites: Faster, cheaper, higher temperature

New players proliferate, increasing CMC materials and manufacturing capacity, novel processes and automation to meet demand for higher part volumes and performance.

Read More