DARPA seeks stealth-enabled tank technologies: Half the weight, double the speed

Ground X-Vehicle Technology (GXV-T) program deadline for Proposer’s Day is Aug. 22, 2014 5:00 pm.

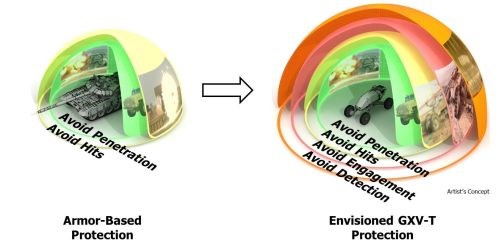

For the past 100 years, protection for ground-based armored fighting vehicles and their occupants has basically mean more armor. Weapons’ ability to penetrate armor, however, has advanced faster than armor’s ability to withstand that assault. As a result, achieving even incremental improvements in crew survivability has required significant increases in vehicle mass and cost.

Increasingly heavy, less mobile and more expensive armored vehicles hinder rapid deployment and maneuverability in often challenging environments. Moreover, larger vehicles are limited to roads and require more logistical support. They are also more expensive to design, develop, field and replace. The U.S. military is now seeking innovative and disruptive solutions to ensure the operational viability of the next generation of armored fighting vehicles.

DARPA has created the Ground X-Vehicle Technology (GXV-T) program to disrupt the current trends in mechanized warfare. GXV-T seeks to investigate revolutionary ground-vehicle technologies that would simultaneously improve vehicle mobility and survivability through new approaches including detection avoidance and evasion of engagement and targeted hits.

GXV-T’s technical goals include the following improvements relative to today’s armored fighting vehicles:

- Reduce vehicle size and weight by 50 percent

- Reduce onboard crew needed to operate vehicle by 50 percent

- Increase vehicle speed by 100 percent

- Access 95 percent of terrain

- Reduce signatures that enable adversaries to detect and engage vehicles

“GXV-T’s goal is not just to improve or replace one particular vehicle—it’s about breaking the ‘more armor’ paradigm and revolutionizing protection for all armored fighting vehicles,” said Kevin Massey, DARPA program manager. “Inspired by how X-plane programs have improved aircraft capabilities over the past 60 years, we plan to pursue groundbreaking fundamental research and development to help make future armored fighting vehicles significantly more mobile, effective, safe and affordable.”

To familiarize potential participants with the technical objectives of GXV-T, DARPA has scheduled a Proposers' Day on Friday, September 5, 2014, at DARPA’s offices in Arlington, Va. Advance registration is required through the registration website: http://www.sa-meetings.com/GXV-T. Space is limited and registration closes Friday, August 22, 2014 at 5:00 PM Eastern Time or when capacity is reached, whichever comes first. DARPA reserves the right to limit the number of attendees from any individual organization.

The DARPA Special Notice document announcing the Proposers’ Day and describing the specific capabilities sought is available at http://go.usa.gov/Edsh. For more information, please email DARPA-SN-14-53@darpa.mil.

DARPA aims to develop GXV-T technologies over 24 months after initial contract awards, which are currently planned on or before April 2015. The GXV-T program plans to pursue research, development, design and testing and evaluation of major subsystem capabilities in multiple technology areas with the goal of integrating these capabilities into future ground X-vehicle demonstrators.

GXV-T seeks a layered technology approach to enable

smaller, faster vehicles in the future to more efficiently and cost-effectively

tackle varied and unpredictable combat situations. Source: DARPA

The GXV-T program provides the following four technical areas as examples where advanced technologies could be developed that would meet the program’s objectives:

-

Radically Enhanced Mobility – Ability to traverse diverse off-road terrain, including slopes and various elevations; advanced suspensions and novel track/wheel configurations; extreme speed; rapid omnidirectional movement changes in three dimensions.

-

Survivability through Agility – Autonomously avoid incoming threats without harming occupants through technologies such as agile motion (dodging) and active repositioning of armor.

-

Crew Augmentation – Improved physical and electronically assisted situational awareness for crew and passengers; semi-autonomous driver assistance and automation of key crew functions similar to capabilities found in modern commercial airplane cockpits.

-

Signature Management – Reduction of detectable signatures, including visible, infrared (IR), acoustic and electromagnetic (EM).

Related Content

Industrializing additive manufacturing in the defense/aerospace sector

GA-ASI demonstrates a path forward for the use of additive technologies for composite tooling, flight-qualified parts.

Read MoreOrbital Composites wins AFWERX award for Starfighter drone fleet

Under the TACFI contract, Orbital is implementing the AMCM process to build 3D printed composite multi-mission UAS aircraft, surpassing $10 million in government awards.

Read MoreCeramic matrix composites: Faster, cheaper, higher temperature

New players proliferate, increasing CMC materials and manufacturing capacity, novel processes and automation to meet demand for higher part volumes and performance.

Read MoreFibreCoat develops radar-absorbing fiber-reinforced composite

Broadband, flexible material offers protection against radiation, heat and electromagnetic interference, and maintains performance across curved surfaces and slanted angles, outperforming existing materials by up to 100 times.

Read MoreRead Next

Next-gen fan blades: Hybrid twin RTM, printed sensors, laser shock disassembly

MORPHO project demonstrates blade with 20% faster RTM cure cycle, uses AI-based monitoring for improved maintenance/life cycle management and proves laser shock disassembly for recycling.

Read MoreCeramic matrix composites: Faster, cheaper, higher temperature

New players proliferate, increasing CMC materials and manufacturing capacity, novel processes and automation to meet demand for higher part volumes and performance.

Read MoreCutting 100 pounds, certification time for the X-59 nose cone

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.

Read More