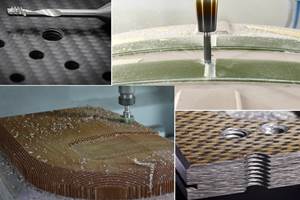

VIDEO: Precision fabrication of honeycomb materials

MachineTek showcases its precision fabrication of honeycomb materials at CAMX 2024.

Share

ÂÌñÏ×ÆÞ editors visited the MachineTek LLC (Carlsbad, Calif., U.S.) booth at CAMX 2024, where Kevin Darroch, president at MachineTek, discussed the company’s expertise in machining honeycomb material.

Transcript excerpt

Scott Francis, CW

MachineTek is a specialist in honeycomb and foam core components for the aerospace and defense industries.

For more than 30 years, it has provided services such as custom machining, deep forming, potting, bonding, fixtures, design and fabrication, as well as engineering support.

Kevin Darroch, MachineTek

Formed in 1992, we’ve been focusing on exactly the same nuanced and specialized services ever since we were incorporated back in those days.

And as you look here, this is an example of the types of honeycomb we would frequently machine. We start off with blocks or sheets of honeycomb. We order to our customer’s specifications. At that point, we bring in their CAD models. We have our engineering team create our own tooling and our own tool paths and then we use, in most cases, our five-axis CNC equipment to create the shapes that you see here.

So this would have started off as a block of honeycomb, Nomex in this case. But as you can tell, we’ve created a fairly complex shape, and this is for an acoustic application. Most of our applications are actually for core components in the aerospace industry — and that means aircraft, but now more spacecraft as well.

Related Content

-

From the CW Archives: Drilling is not for the faint of heart

This edition of From the CW Archives revisits CW’s first plant tour — a visit to the F-35 FAL in Fort Worth, Texas — and a story by Ginger Gardiner a few years later. Both offer lessons on how to perform stacked drilling through composite and metallic materials.

-

Ruckus Composites, Aerospace grows in-house composites machining, measurement and inspection

Recent in-house technology investments set Ruckus up to meet advanced composite inspection and precision machining demand.

-

Fraunhofer IFAM MTC closes gap between industrial robots, machine tools

Machine tool robot (MTC) features improved milling kinematics that enable versatile, efficient and high-precision machining of composites and hard metals with a manufacturing tolerance of up to 0.1 millimeter.

Related Content

From the CW Archives: Drilling is not for the faint of heart

This edition of From the CW Archives revisits CW’s first plant tour — a visit to the F-35 FAL in Fort Worth, Texas — and a story by Ginger Gardiner a few years later. Both offer lessons on how to perform stacked drilling through composite and metallic materials.

Read MoreRuckus Composites, Aerospace grows in-house composites machining, measurement and inspection

Recent in-house technology investments set Ruckus up to meet advanced composite inspection and precision machining demand.

Read MoreFraunhofer IFAM MTC closes gap between industrial robots, machine tools

Machine tool robot (MTC) features improved milling kinematics that enable versatile, efficient and high-precision machining of composites and hard metals with a manufacturing tolerance of up to 0.1 millimeter.

Read MoreOptimizing machining for composites: Tool designs, processes and Industry 4.0 systems

Hufschmied moves beyond optimized milling and drilling tools to develop SonicShark inline quality control system and Cutting Edge World cloud platform for optimized tool use and processes.

Read MoreRead Next

VIDEO: Recycling and machining carbon fiber scraps

Elevated Materials has partnered with ‪Toray Composite Materials America, Inc. to collect and upcycle reclaimed carbon fiber scraps into large billet laminates, which can then be cut into various parts using CNC mills.

Read MoreVIDEO: AI, cameras and lasers for FOD detection

Virtek Vision demonstrates its Iris AI technology at CAMX 2024. It combines laser projection with machine learning software to detect foreign object debris during a composite layup.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More

.jpeg;maxWidth=300;quality=70)