Custom-engineered hydraulic presses are build for long-term reliability

CAMX 2025: Macrodyne Technologies’ turnkey equipment solutions, from presses to integrated automation systems, offer a range of operational benefits that address demanding production.

Share

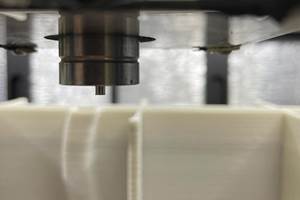

A 3,000-ton sheet molding compound (SMC) press. Source | Macrodyne

(Ontario, Canada) is a large press manufacturer and a trusted supplier of advanced composite molding systems for global manufacturers. With deep expertise in compression molding, RTM, prepreg applications and heated platen presses, Macrodyne provides fully integrated solutions engineered for demanding production environments.

The company’s hydraulic and servo presses are custom built to form thermoplastics, thermosets, elastomers and rubber materials with consistent precision and repeatability. From small-batch runs to large-scale production, Macrodyne says it helps its customers tackle complex part geometries, tight tolerance requirements and evolving material needs, all while optimizing cycle times and throughput.

What sets Macrodyne apart is its commitment to integration. Every Macrodyne system is designed with automation in mind, ensuring smooth communication between press and auxiliary equipment. Material handling, heating and cooling, trimming and unloading are all part of a unified system, rather than bolt-on additions.

The company emphasizes that all of its builds are tailored to the specific needs of customers and backed by full project support from concept through commissioning and beyond. Macrodyne’s engineering team works closely with its customers’ to ensure every aspect of a press line is designed for performance, longevity and minimal downtime.

Macrodyne has manufacturing locations in Canada, the U.S., Mexico and Germany, offering regional support with global reach.

Related Content

-

Mold 3D printing helps automate composite bathtub, shower production

As part of its efforts to automate as much of its production process as it can, Lyons Industries acquired a Massivit 10000 additive manufacturing system to quickly produce high-performance molds and support fixtures.

-

Laser cleaning in composites manufacturing

Laser cleaning technologies for cleaning production molds for composites offer alternatives to harsher, less-friendly methods with features like automation and higher power cleaning.

-

Plant tour: BeSpline/Addcomp, Sherbrooke, QC, Canada

Composites automation specialist increases access to next-gen technologies, including novel AFP systems and unique 3D parts using adaptive molds.

Related Content

Mold 3D printing helps automate composite bathtub, shower production

As part of its efforts to automate as much of its production process as it can, Lyons Industries acquired a Massivit 10000 additive manufacturing system to quickly produce high-performance molds and support fixtures.

Read MoreLaser cleaning in composites manufacturing

Laser cleaning technologies for cleaning production molds for composites offer alternatives to harsher, less-friendly methods with features like automation and higher power cleaning.

Read MorePlant tour: BeSpline/Addcomp, Sherbrooke, QC, Canada

Composites automation specialist increases access to next-gen technologies, including novel AFP systems and unique 3D parts using adaptive molds.

Read MoreSAM XL demonstrates closed-loop digital methodologies via full-size aerocomposite parts development

PeneloPe Project’s modular, zero-defect manufacturing deliverables are being highlighted in an upcoming video that demonstrates the resulting aerospace pilot line’s feasibility.

Read MoreRead Next

Cutting 100 pounds, certification time for the X-59 nose cone

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.

Read MoreScaling up, optimizing the flax fiber composite camper

Greenlander’s Sherpa RV cab, which is largely constructed from flax fiber/bio-epoxy sandwich panels, nears commercial production readiness and next-generation scale-up.

Read MoreUltrasonic welding for in-space manufacturing of CFRTP

Agile Ultrasonics and NASA trial robotic-compatible carbon fiber-reinforced thermoplastic ultrasonic welding technology for space structures.

Read More