Sheet Molding Compound

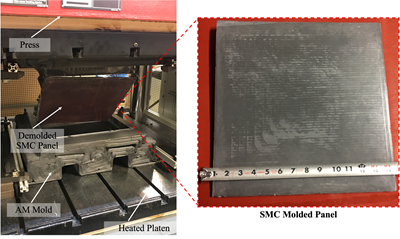

Can 3D printing debottleneck prototype tool production?

Preliminary IACMI/ORNL study evaluates viability of using polymer additive tooling to compression mold SMC.

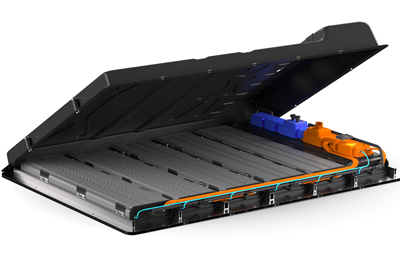

Read MoreEvonik, Vestaro consortium partners develop EV Pure Performance Battery

Novel approach to high-voltage GF-SMC battery module housing design increases battery cell capacity, enables flexible adjustment of the number of modules and can be catered to a variety of vehicle architectures.

Read MoreEnvisioning high-volume, 100% composite wheels

Vision Wheel debuted its first carbon fiber composite wheel at CAMX 2021, claiming its low-cost, high-volume process can be scaled up for performance vehicles, UTVs and — ultimately — passenger EVs.

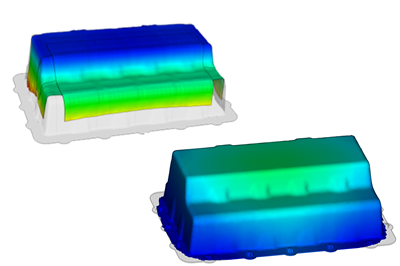

Read MoreHybrid battery cover: CAE approach

A Q&A with Benedikt Fengler, co-founder and composites simulation specialist for Simutence provides a more in-depth take on moldfilling, warpage and assembly simulations performed in HRC Group’s SMC battery cover feasibility study.

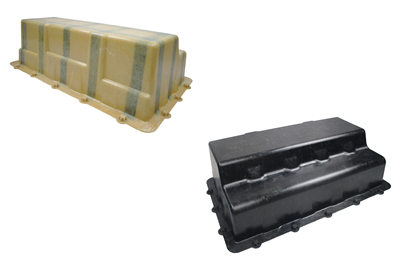

Read MoreSMC material configurations tailored to automotive battery enclosure design

SMC battery cover offers various module configurations, levels of performance, mass and cost for electric vehicles.

WatchAVK, European Alliance SMC BMC announce SMCCreate 2022 conference

New conference in Atwerp, Belgium, April 6-7, 2022 covers topics concerning designing in SMC and BMC composites, provides insights from concept to manufacture.

Read MoreAOC, Zoltek, Astar develop novel CF-SMC for high-performance automotive parts on an industrial scale

The combination of Zoltek’s low-cost split-tow fiber and Daron SMC resin from AOC and Astar produces CF-SMC with enhanced mechanical properties, low part emissions, cost efficiency and design freedom.

Read MoreCAMX 2021 exhibit preview: Schmidt & Heinzmann

Schmidt & Heinzmann showcases its product portfolio, which features the AutoCut 2D free-form cutting unit, Cube digitized SMC line and virtual reality.

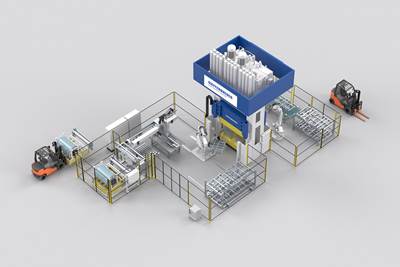

Read MoreDieffenbacher automates SMC lines for enhanced productivity and efficiency

Quick-change cutting system reduces changeover times to six to seven minutes, and ensures maximum reproducibility, even with the complex geometries.

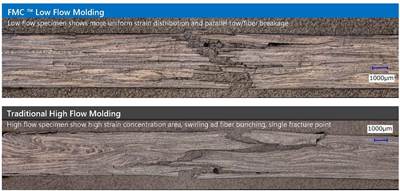

Read MoreForged molding compound: Extending SMC capabilities

New material, design, process combination approaches prepreg performance with chopped carbon fiber SMC.

Read More