Search Results

Showing 21 – 30 of 453 results

The wind energy market has long been considered the world’s largest market, by volume, for glass fiber-reinforced polymer (GFRP) composites — and increasingly, carbon fiber composites — as larger turbines and longer wind blades are developed, requiring higher performance, lighter weight materials. The outer skins of wind and tidal turbine blades generally comprise infused, GFRP laminates sandwiching foam core. Inside the blade, rib-like shear webs bonded to spar caps reinforce the structure. Spar caps are often made from GFRP or, as blade lengths lengthen, pultruded carbon fiber for additional strength.

Completed prototype for Georgian Aerospace uses a low-dielectric epoxy prepreg on quartz fabric, which has passed radio frequency testing with results equivalent to traditionally higher-cost, low-dielectric matrix options.

The Marservis PROeco is a mass transportation marine vessel using Bcomp natural fiber for interior parts in place of standard materials.

The composites-intensive fourth-generation model by the Aachen-based Sonnenwagen team, backed by Covestro, prepares for the October 2023 Bridgestone World Solar Challenge.

The world title-holding, Belgium racing team is producing its tenth composites-intensive solar car using Jetcam Expert nesting software.

As Aptera moves into building validation vehicles, the live June 27 reveal will closely represent the sEVs the company expects to assemble for customers.

CAMX 2023: Together, EconCore and ThermHex are providing a first look at new product variations for additional lightweight opportunities, including high-performance thermoplastic cores and solar panels with a honeycomb structure.

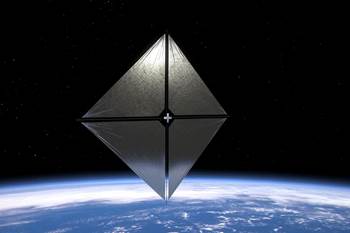

Sunlight-based propulsion system, supported by carbon fiber-reinforced booms, will undergo weeks-long testing to demonstrate and verify its capabilities.

Skydweller Aero has successfully completed its first uncrewed autonomous flight test for its composite unmanned aerial system (UAS), aiming to deliver solar-powered, extreme flight endurance.

Netherlands-based EconCore and Solarge have collaborated to develop a composite solar panel that offers weight savings of up to 65%.

RWC built and delivered solar array substrate panels from trace/lead-integrated skins that enable direct integration with solar cells, saving weight and time.