Tepex thermoplastic composites demonstrate fire resistance for EVs

Bond-Laminates’ continuous-fiber-reinforced thermoplastic composite has passed flammability tests for car interiors.

Bond-Laminates’ Tepex continuous-fiber-reinforced thermoplastic composite materials have structures designed to resist fire without flame-retardant additives. This is a result of tests conducted by the Lanxess subsidiary partly in cooperation with external testing institutes.

“The tests also showed that our composites are highly suitable for structural components and housing components in high-voltage batteries for electric vehicles, which, for safety reasons, need to have excellent flame-retardant properties,” says Dr. Stefan Seidel, head of Research and Development at Bond-Laminates. “The materials here present a lightweight alternative to aluminum. They enable cost-effective component solutions thanks to the cost-reducing integration of functions and simple processing in the hybrid molding method without the need for rework.”

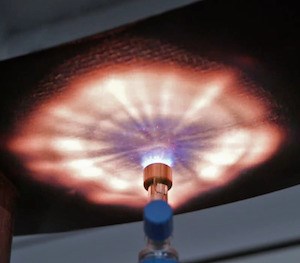

Non-flame-retardant Tepex variants were tested in a fire pan test in which the specimen lies flat over a tub of burning fuel and is exposed to the fire directly for 70 seconds and less directly for 60 seconds. This test is a realistic reflection of the fire situations Tepex might face in typical applications such as underbody paneling components, Bond-Laminates says.

With electric vehicle powertrains in mind, Bond-Laminates has tested the fire behavior of overmolded, polyamide 6-based Tepex. A “HiAnt carrier” was used. This is a U-shaped profile made of Tepex, the inside of which is reinforced with crosswise ribs made of various polyamide 6 types such as Durethan, with or without a flame-retardant package. The specimen is exposed to a 900 °C flame in six positions for between 30 seconds and five minutes, including on the polyamide ribs and areas that have not been overmolded.

“Using non-flame-retardant Tepex with a flame-retardant injection molding material offers a very substantial safety margin for the design of flame-retardant components. We see enormous potential for this material combination to be applied in high-voltage battery components such as housings and partitions, but also in floor plates for inductive battery charging systems,” says Seidel.

Tepex with inherent flame-retardant properties exhibit:

• Fabric structure and high fiber content prevent flames from spreading

• Flame-retardant product variants with UL 94 V-0 classification

• Suitable for use in flame-resistant high-voltage battery components and inductive charging

Related Content

-

Bladder-assisted compression molding derivative produces complex, autoclave-quality automotive parts

HP Composites’ AirPower technology enables high-rate CFRP roof production with 50% energy savings for the Maserati MC20.

-

JEC World 2024 highlights: Thermoplastic composites, CMC and novel processes

CW senior technical editor Ginger Gardiner discusses some of the developments and demonstrators shown at the industry’s largest composites exhibition and conference.

-

Plant tour: Collins Aerospace, Riverside, Calif., U.S. and Almere, Netherlands

Composite Tier 1’s long history, acquisition of stamped parts pioneer Dutch Thermoplastic Components, advances roadmap for growth in thermoplastic composite parts.