Solvay introduces high-temperature PEEK polymer

KetaSpire PEEK XT promises the chemical resistance of standard PEEK plus significantly higher strength and stiffness at elevated temperatures.

Source | Solvay

According to Solvay,​​​​ (Alpharetta, Ga., U.S.) the company’s KetaSpire PEEK XT, introduced at the K 2019 trade show in Düsseldorf, Germany, is the industry’s first true high-temperature polyetheretherketone (PEEK). This material reportedly offers the chemical resistance of standard PEEK plus significantly higher strength and stiffness at elevated temperatures.

Compared to standard PEEK, KetaSpire PEEK XT is said to have a 20°C (36°F) higher glass transition temperature, at 170°C (338°F), and a 45°C (81°F) higher melting temperature, at 20°C (36°F). The material is said to exhibit significantly higher strength and stiffness at elevated temperatures compared to standard PEEK, with a 400% higher tensile modulus and nearly 50% higher tensile strength at 160°C (320°F).

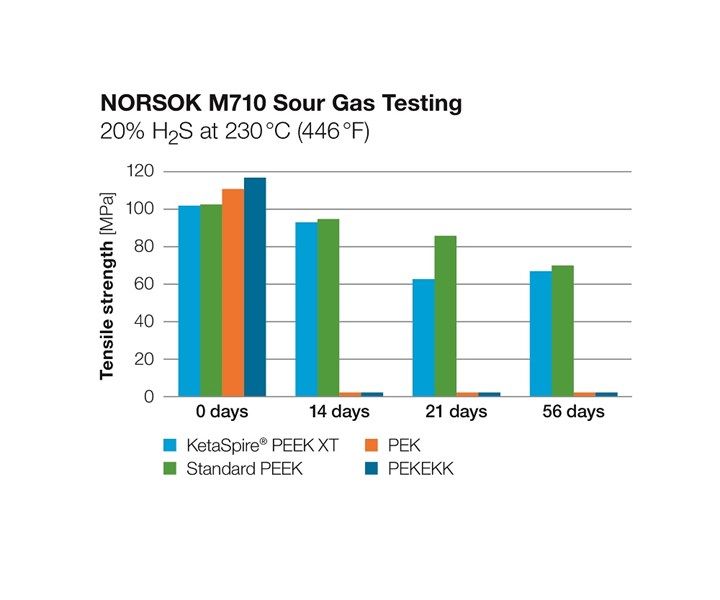

According to Solvay, other high-temperature polyketones, including polyetherketone (PEK), polyetherketoneketone (PEKK) and polyetherketone-etherketone-ketone (PEKEKK), alter the 2:1 ether-to-ketone ratio of a true PEEK polymer, losing some of PEEK’s chemical resistance. KetaSpire PEEK XT maintains this ratio, enabling it to superior chemical resistance to other high-termperature polyketones while exhibiting similar thermal properties.

In addition, KetaSpire PEEK XT is said to show superior electrical properties at 250°C (482°F) compared to standard PEEK, increasing dielectric strength by 50% and volume resistivity by an order of magnitude.

The material is available globally in neat, 30% glass fiber, and 30% carbon fiber-reinforced injection molding and extrusion grades, as well as in fine powder form for compression molding and as coarse powder for compounding. Applicable industries include oil & gas, electrical/electronics, wire coatings and automotive.

Related Content

-

Plant tour: Collins Aerospace, Riverside, Calif., U.S. and Almere, Netherlands

Composite Tier 1’s long history, acquisition of stamped parts pioneer Dutch Thermoplastic Components, advances roadmap for growth in thermoplastic composite parts.

-

Carbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.

-

Development of a composite liquid hydrogen tank for commercial aircraft

Netherlands consortium advances cryogenic composites testing, tank designs and manufacturing including AFP, hybrid winding, welding of tank components and integrated SHM and H2 sensors for demonstrators in 2025.

.jpg;width=70;height=70;mode=crop)