Royal DSM presents glass-filled polypropylene granules for 3D printing

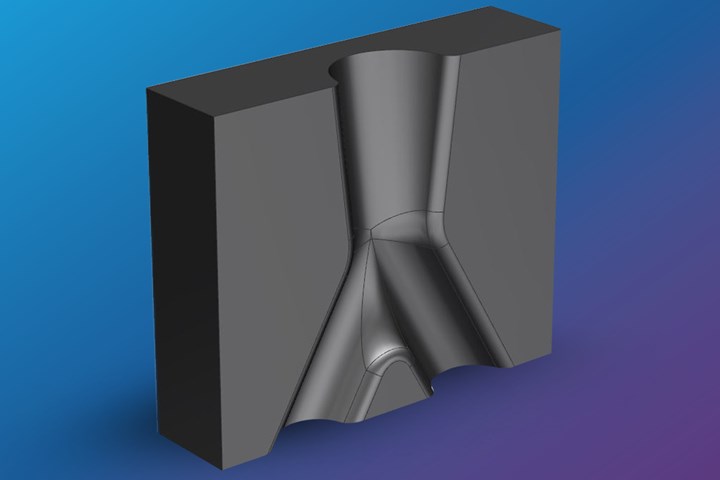

The glass-filled polypropylene (PP), optimized for fused granulated fabrication (FGF) is suitable for additive manufacturing of structural and demanding applications.

Source | Royal DSM

(Geleen, Netherlands) a global science-based company in nutrition, health and sustainable living, announced on August 13 new glass-filled polypropylene (PP) pellet material which has been developed specifically for 3D printing, enabling easy and consistent production of structural and demanding applications using fused granulate fabrication technology.

Widely used for its mechanical, thermal and chemical performance, DSM notes that PP is the second most frequently used polymer worldwide. Automotive, industrial or infrastructure manufacturers looking to adopt additive manufacturing technology for low volume or decentralized production — where the elimination of tools helps decrease cost — are said to desire to use the same material they are familiar with from traditional manufacturing.

To meet this growing need, DSM has unveiled its glass-filled PP for fused granulate fabrication (FGF), suitable for additive manufacturing. Arnilene AM6001 GF (G) — the (G) stands for granulates — is said to stem from the same base material used in high volume production and is optimized for FGF 3D printing. It is ideally suited for direct printing of structural, lightweight applications for automotive, infrastructure and water management, as well as tooling. DSM says the product secures all of the desirable mechanical, thermal and chemical performance of glass filled PP with the flexibility of a proven 3D process.

According to the company, the material’s low carbon footprint, due to reduced energy consumption, and its low LCA (Life Cycle Assessment), inherent to the PP’s chemistry, make it a sustainable solution.

Related Content

-

Creating a composite battery insert-stud solution for EV trucks

Bossard worked with an OEM and Tier supplier team to meet tight electrical insulation and packaging tolerances while reducing tooling, molding and assembly costs.

-

JEC World 2024 highlights: Glass fiber recycling, biocomposites and more

CW technical editor Hannah Mason discusses trends seen at this year’s JEC World trade show, including sustainability-focused technologies and commitments, the Paris Olympics amongst other topics.

-

SMC composites progress BinC solar electric vehicles

In an interview with one of Aptera’s co-founders, CW sheds light on the inspiration behind the crowd-funded solar electric vehicle, its body in carbon (BinC) and how composite materials are playing a role in its design.