Kordsa targets phenolic-based sandwich panel toward aircraft interiors

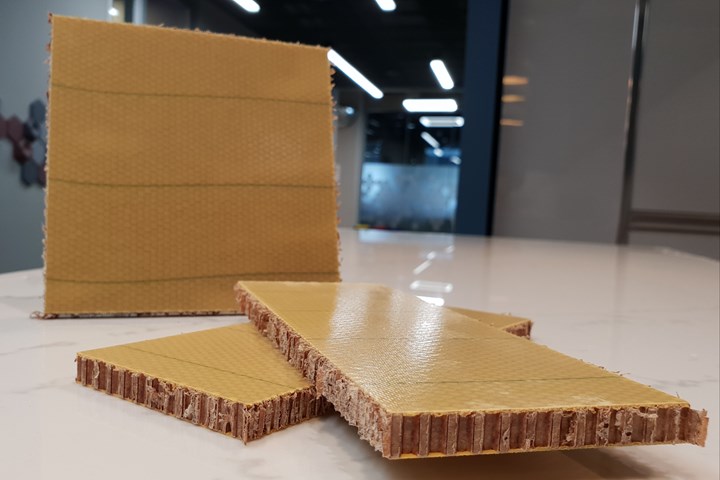

The sandwich panels comprise glass fiber/phenolic skins surrounding a Nomex honeycomb core.

Source | Kordsa

Tire, construction reinforcement and composites technologies company Kordsa (Izmut, Turkey) has introduced a new line of honeycomb composite sandwich panels for the cabin interior of commercial airplanes. The company’s Composites Center of Excellence (CTCE), founded in 2016, played a significant role in the development of the technology. The material, comprised of glass fiber in a phenolic matrix surrounding a honeycomb core, is targeted toward aircraft galley applications. Kordsa selected phenolic for its flame-retardancy. The honeycomb core, provided by (San Marco, Calif., U.S.), a subsidary of Kordsa, is also phenolic-based. Each honeycomb cell is hexagonal-shaped and measures 3.2 millimeters wide. Kordsa says its composite sandwich panels can withstand greater bending loads than the leading brand and is able to withstand peel loads in either direction.

Related Content

-

Infinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

-

Combining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

-

Industrializing additive manufacturing in the defense/aerospace sector

GA-ASI demonstrates a path forward for the use of additive technologies for composite tooling, flight-qualified parts.