University of Kentucky, ORNL partner to turn coal into high-value carbon fiber

The $10 million research partnership will focus on creating energy-efficient and cost-effective processes for the manufacturing of carbon fiber.

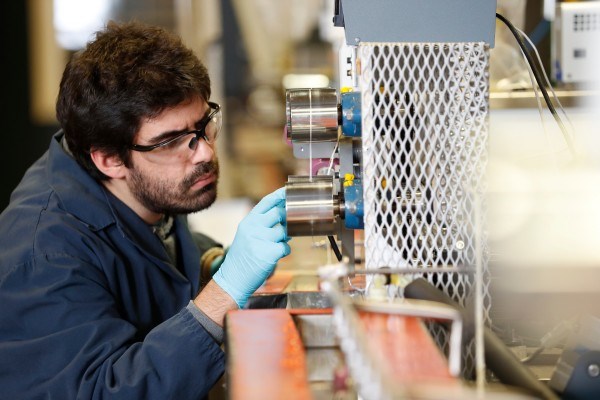

Ruben Sarabia-Riquelme, research engineer at the University of Kentucky Center for Applied Energy Research, works with a carbon fiber spinline. Source | Mark Mahan

It was reported on August 20 that the (UK CAER; Lexington, Ky., U.S.) and the U.S. Department of Energy’s (DOE) Oak Ridge National Laboratory (ORNL; Oak Ridge, Tenn., U.S.) are teaming up on a $10 million project to transform coal into high-value carbon fibers and composites. The project was funded by the DOE’s Office of Fossil Energy, and the collaboration will allow both organizations to maximize their respective expertise in the field.

According to UK CAER, the project, titled “C4WARD: Coal Conversion for Carbon Fibers and Composites,” seeks to develop the fundamental and translational science and engineering necessary to create energy-efficient and cost-effective processes for manufacturing carbon fibers with tunable properties. It will address challenges associated with coal processing, variability in coal feedstocks and carbon fiber manufacturing scale up from laboratory to semi-production scale.

The university notes that coal-to-carbon fiber research shows great promise to positively impact the nation’s sluggish coal industry. In 2019, it is said that U.S. coal production, consumption and employment reached their lowest levels in 40 years. UK CAER says these trends are likely to persist as coal continues to lose market share to natural gas and renewable generation in the electric power sector. Recent studies suggest that U.S. coal utilization for coal-to-products applications has the potential to reach utilization levels on the same order of magnitude as that of steam coal.

Further, says the university, the market for carbon fibers, continues to grow, driven by increased use in aerospace and defense applications as well as lightweighting of automobiles. New market growth in other high-volume applications — such as thermal insulation for buildings and materials for construction and infrastructure — also show great promise. The market for carbon fibers is expected to grow at a compound annual growth rate of 12% through 2024.

, guided by director Rodney Andrews and associate director Matt Weisenberger, will lead the effort to convert a variety of coal feedstocks into carbon fibers and composites. Home to the largest carbon fiber spinline facility at any academic institution in North America, UK CAER says it will be working with ORNL to optimize coal-derived pitch processing for carbon fiber and composites development. CAER will produce laboratory-scale quantities of carbon fiber to develop structure-property relationships between the feed coal material and the resultant carbon fiber to develop processing-structure-properties relationships.

The university says ORNL will be leading efforts in materials characterization, technoeconomic analysis and technology-to-market portions of the project. More specifically, ORNL will be using its expertise in chemistry and high-performance computing to correlate the molecular structure of coal with its processability, identifying optimum pitch compositions to fabricate carbon fibers with tunable properties.

Additionally, CAER and ORNL will also collaborate to develop process conditions for scaling up fiber production at the Carbon Fiber Technology Facility (CFTF) at ORNL, DOE’s only designated user facility for carbon fiber innovation. The CFTF, a 42,000-square-foot facility, reportedly provides a platform for identifying high-potential, low-cost raw materials including textile, lignin, polymer and hydrocarbon-based precursors. Using the CFTF, ORNL is developing optimal mechanical properties for carbon fiber material, focusing on structure property and process optimization.

The facility is also said to be capable of custom unit operation configuration and has a capacity of up to 25 tons per year, allowing industry to validate conversion of its carbon fiber precursors at semi-production scale.

“Adding value to Kentucky and the nation’s economy has long been a hallmark of our research and outreach at the UK Center for Applied Energy Research,” Andrews says. “This coal-to-carbon fiber project allows us to continue that tradition in new and exciting ways and alongside a partner in Oak Ridge National Laboratory that is known across the globe for their innovation, discovery and technology transfer programs.”

Related Content

Hands-on composites training, M&P engineering consulting services

CAMX 2025: Set up in its new facility in Spark, Nevada, Abaris is highlighting its training capabilities, course offerings, and customer consultation and technical assistance.

Read MoreAltair, NIAR sign MOU to build aerospace innovation space

Collaboration will expand digital twin adoption, empower aerospace startups and speed up product development and certification processes.

Read MoreReducing accidental separator inclusion in prepreg layup

ST Engineering MRAS discusses the importance of addressing human factors to reduce separator inclusion in bonded structures.

Read MoreAMRC Training Centre introduces composites apprenticeship opportunity

With partners McLaren and Teledyne CML Composites, the Training Center will train new composites technicians in South Yorkshire to build up the future industry workforce.

Read MoreRead Next

Next-gen fan blades: Hybrid twin RTM, printed sensors, laser shock disassembly

MORPHO project demonstrates blade with 20% faster RTM cure cycle, uses AI-based monitoring for improved maintenance/life cycle management and proves laser shock disassembly for recycling.

Read MoreUltrasonic welding for in-space manufacturing of CFRTP

Agile Ultrasonics and NASA trial robotic-compatible carbon fiber-reinforced thermoplastic ultrasonic welding technology for space structures.

Read MoreCutting 100 pounds, certification time for the X-59 nose cone

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.

Read More