Soling, Magnum Venus Products partnership produces LRTM composite domes

Incorporating the LRTM process enabled Soling to produce the largest LRTM part by volume manufactured in Colombia.

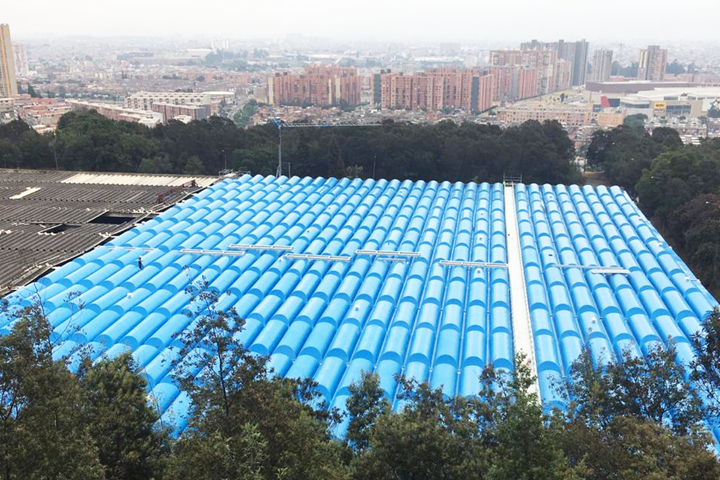

Aerial view of the completed phase one project to develop water storage tanks for Bogota Water Utility. Source | MVP

Magnum Venus Products (MVP, Knoxville, Tenn., U.S.) and its Colombian distributor, (Medellin, Colombia) reported its collaboration with (Soling, Colombia), a company dedicated to providing corrosion solutions, to develop drinking water storage tanks for Bogota’s water utility company.

Soling was initially presented with the project in 2018 to develop a 143-meter-by-109-meter (149-foot-by-358-foot) drinking water storage tank, as the water utility company’s current operation had frequent aqueduct cover breaks requiring costly repairs and thus, increased risk of potable water contamination. Although Soling proposed a series of 7.6-meter-by-2.4-meter (25-foot-by-8-foot) semicircular domes, with a surface area of approximately 207 square feet per piece, it was soon realized that Soling would be required to manufacture 840 domes in order to cover the total project area. Partnering with MVP enabled both teams to devise an effective process to reach a high production throughput with very low post-processing requirements. Furthermore, Soling was already familiar with MVP, having relied on its equipment to provide solutions for its customers.

According to MVP, the Bogota Water Utility project required the manufacturing of up to eight 320- kilogram pieces per day, a net increase in consumption of more than two tons of resin per day. To meet the need for a highly repeatable process producing good surface finish with isophthalic gelcoat on both sides, MVP recommended vacuum-assisted closed molding, or light resin transfer molding (LRTM) as the most suitable process.

MVP used its Patriot Innovator High Volume RTM System which, designed for injecting polyester, vinyl ester and methacrylate resins and catalyst at controlled pressures, is capable of injecting material at a high rate with a single unit. The injection was performed with the LRTM process, consisting of high-volume turbo autosprue valves (TAS), universal couplings, seals and mold accessories. A low viscosity resin formulated by Colombian chemical manufacturer, (Antioquia, Colombia), is said to have been incorporated.

Mold developed by Soling and MVP used in manufacture of new storage domes. Source | MVP

According to MVP, the full production cycle for one piece, from the preparation of the mold to the extraction of each dome, took four hours with an injection time of only 40 minutes. In an eight-hour work shift, two pieces were able to be manufactured from the application of gelcoat — using MVP’s multicolor gelcoat system — to the trimmed and finished piece, ready for shipment.

These new composite dome covers are expected to last much longer than those previously built with traditional materials, contends MVP, which were prone to breakage and carried huge maintenance costs for Bogota’s water utility company. The company notes that the success of this project has raised the bar on size, efficiency and production volume for the composites industry in Colombia.

To date, MVP says the Bogotá aqueduct domes are the largest parts by volume manufactured through a LRTM process in Colombia. The full implementation of the project is said to have taken only six months thanks to the collaborative effort between itself, Minepros SAS, Soling and Andercol; MVP’s team, including Latin America sales manager Andrés F. Collazos, and technical specialist Herik Navarro, provided critical equipment expertise and technical support. MVP’s distributor in Colombia, Minepro SAS, coordinated many of the engineering, sales and technical aspects during the process implementation, including equipment and fine-tuning of the LRTM process. On the materials side, Andrés Franco and the service and technical development team in R&D at Andercol, also played a key role in the formulation of the low-viscosity resin, as well as early support with key design elements of the process. Additionally, Soling’s engineering team, led by Rodrigo Vergara, was in charge of integrating all information and data, and setting up the process.

“Partners like MVP enable us to bring these projects to life and deliver effective solutions. Their customer service and technical expertise is second to none,” says Soling engineer, Javier Moreno.

“Through this collaboration, we were able to redefine what is possible for the local industry.” Soling says it is planning to continue producing covers for the second stage of the project and explore more MVP closed molding solutions for even higher manufacturing volumes of various large-scale composite parts.

Read the full case study .

Related Content

Injection molding expertise achieves composites mobility innovation

JEC World 2025: A partner in three JEC Award products, Engel demonstrates how its injection molding equipment can set new benchmarks in applications like bike handlebars and interior vehicle components.

Read MoreComposites end markets: Electronics (2025)

Electronic and smart device innovations achieved through the use of advanced materials ranging from thermoplastic composites to biomaterials emphasize high-volume production and sustainability.

Read MoreCarbon Mobile carbon fiber powers handheld gaming platform

HyRECM technology effectively stabilizes carbon fiber’s electrical and antenna properties, enabling development of next-gen electronics, such as the Snapdragon G3x Gen 2.

Read MoreBcomp, Siux bring natural fiber composites to padel tennis

Flax fibers enter the court through Siux’s GEA padel racquets, delivering high-performance, well-balance sports equipment to a rapidly growing sports market.

Read MoreRead Next

Scaling up, optimizing the flax fiber composite camper

Greenlander’s Sherpa RV cab, which is largely constructed from flax fiber/bio-epoxy sandwich panels, nears commercial production readiness and next-generation scale-up.

Read MoreUltrasonic welding for in-space manufacturing of CFRTP

Agile Ultrasonics and NASA trial robotic-compatible carbon fiber-reinforced thermoplastic ultrasonic welding technology for space structures.

Read MoreNext-gen fan blades: Hybrid twin RTM, printed sensors, laser shock disassembly

MORPHO project demonstrates blade with 20% faster RTM cure cycle, uses AI-based monitoring for improved maintenance/life cycle management and proves laser shock disassembly for recycling.

Read More