Shin-Etsu Chemical Co. to manufacture, market new hydrocarbon resins for 5G electronics, aerospace

Developed per a licensing agreement with materials company Novoset LLC, the resins are said to possess ultra-low dielectric loss properties for electronics.

Materials company (Peapack, New Jersey, U.S.) announced on Dec. 26 that it has signed a licensing agreement with Shin-Etsu Chemical Co. Ltd. (Tokyo, Japan) for the manufacturing and marketing of modified hydrocarbon resins based on Novoset’s intellectual property, which will target applications in electronics, automotive and aerospace.

The new resins are said to exhibit ultra-low dielectric loss properties at high frequencies, low coefficient of thermal expansion (CTE), very low moisture absorption, high glass transition temperatures (Tg) and long-term thermo-oxidative stability at 250°C.

These products are targeted for a range of 5G applications such as chip encapsulation, underfill, molding compounds, millimeter wave base station infrastructure for smartphones, high layer count printed circuit board (PCB) servers, routers for cloud computing and semiconductor packaging. Novoset says that these resins are specifically designed for use in devices enabling next-generation 5G technologies like Advanced Driver Assistance Systems (ADAS).

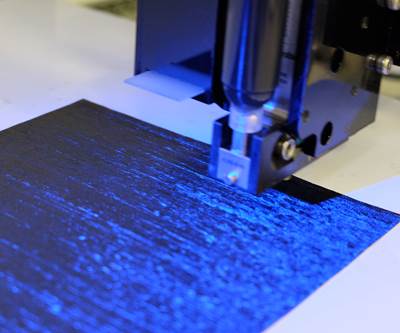

These products are also reportedly suitable for various aerospace applications where ultra-low dielectric, low moisture properties and high Tg are required. In addition, the materials can be used in aerospace processes such as resin infusion, hot melt prepreg, filament winding and other liquid processes.

Novoset officials said in a press release, “We are pleased to collaborate with Shin-Etsu Chemical, Japan to commercialize these unique products to address material gaps and difficult-to-process current 5G materials (targeted to millimeter wave substrates, antennas) such as liquid-crystal polymers (LCP), polyimides (PI) and polytetrafluorethylene (PTFE). Shin-Etsu Chemical is our ideal collaborator due to their in-house 5G applications and global footprint in semiconductors and other high-end industries.”

The resins were developed at Novoset Technology Center in Berkeley Heights, N.J., U.S. Under this agreement, Shin-Etsu Chemical Co. Ltd. will manufacture the resins globally in the relevant electronics industries and market the products under SLK name. Novoset will market the products in aerospace, oil and gas, and other industries, and will continue to improve and expand the range of products according to market needs.

Related Content

MFFD longitudinal seams welded, world's largest CFRTP fuselage successfully completed

Fraunhofer IFAM and partners have completed left and right welds connecting the upper and lower fuselage halves and sent the 8×4-meter full-scale section to ZAL for integration with a cabin crown module and testing.

Read MorePlant tour: Collins Aerospace, Riverside, Calif., U.S. and Almere, Netherlands

Composite Tier 1’s long history, acquisition of stamped parts pioneer Dutch Thermoplastic Components, advances roadmap for growth in thermoplastic composite parts.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MorePlant tour: Sekisui Aerospace, Orange City, Iowa, Renton and Sumner, Wash., U.S.

Veteran composites sites use kaizen and innovation culture to expand thermoplastic serial production, 4.0 digitization and new technology for diversified new markets.

Read MoreRead Next

Nanomaterials: Products, supply chain mature for next-gen composites

Development spans 3D and thermoplastic nanocomposites, nano-CMCs for hypersonics and nanomaterials safety and toxicity.

Read More5G-enabled smart cities bring opportunities for pultruded composites

A recent report explores the utility of radio frequency-transparent pultruded composite materials for integrating 5G mobile networks into urban infrastructure.

Read MoreCeramic matrix composites: Faster, cheaper, higher temperature

New players proliferate, increasing CMC materials and manufacturing capacity, novel processes and automation to meet demand for higher part volumes and performance.

Read More.jpg;width=70;height=70;mode=crop)