Scheurer Swiss supports ETH Zürich composite hybrid rocket motor development

Company supports the university focus project with its composite engineering know-how and networking capabilities for the production of a third-generation rocket motor that aims to reach an altitude of 30,000 feet.

Daedalus team. All photo credit: ARIS

Scheurer Swiss GmbH (Volketswil, Switzerland), a composite company, reported on July 5 that it has supported the , a concept pursued by six mechanical engineering students from public research university ETH Zürich (Switzerland) to produce a lightweight, third-generation hybrid rocket motor for this year’s ARIS Piccard sounding rocket, a launch vehicle designed to take measurements and perform scientific experiments during its suborbital flight. In addition to providing its high-performance composite engineering expertise, Scheurer Swiss helped network the project team with the appropriate companies.

ARIS is a multi-project organization founded in 2017 by students at ETH Zürich to promote spaceflight in Switzerland. Together, budding engineers, scientists and economists have since been developing systems for aerospace with the goal of advancing humanity. The Daedalus project, specifically, aims to use a hybrid rocket motor — which combines a solid fuel with a liquid oxidizer, preventing unintentional ignition — to reach an altitude of 30,000 feet (about 9,150 meters) and win the 2021 Spaceport America Cup in New Mexico, said to be the largest academic rocket engineering competition in the world. The team also expects to compete at EuRoc, said to be the first university rocket launch competition in Europe.

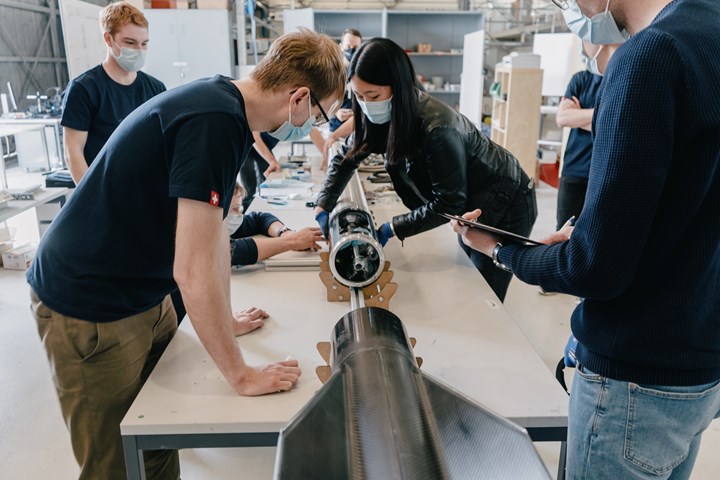

The project kicked off in September 2020, and after the concept and design phase, which is said was supported by valuable input from industry and research experts, the final design of the hybrid rocket motor was in place by December 2020. According to the team, the major challenge of the project has been the integration of the engine into the Piccard rocket, which placed stringent requirements for the engine design. For this reason, the six-member project team worked closely with experts in lightweight construction. To achieve their ambitious goals, Scheurer Swiss, with its many years of experience in composites, was felt to be ideally suited for collaboration.

After an extensive two-month test campaign, during which the performance of the engine in the rocket was tested, the ETH Zürich team reports that its hybrid rocket engine has successfully completed static field testing and is ready for the first hybrid flight.

Daedalus team: Julian Frei (top left); Leona Gui (top middle); Severin Meyer (top right); Alex Brandes (bottom left); Adrian Fuhrer (bottom middle); and Aaron Ehrat.

“The course of the entire test campaign was successful and the data collected shows that we are ready for the flight of our engine in the rocket,” says Adrian Fuhrer, hybrid rocket engineer. “The great support that Scheurer Swiss provided us, especially at the beginning of the project, in the field of composite engineering and the networking with other competent partners for lightweight construction and fiber composite technology, was very valuable for us and made the project possible in the first place.”

According to Scheurer Swiss CEO, Dominik Scheurer, the Daedalus project exemplifies how highly efficient technical systems with great potential for success can be developed with the use of fiber-reinforced composite materials and lightweight construction technologies. “We congratulate the Daedalus team on the successful test series and are pleased that we were able to support the team with our engineering expertise and network it with our partner companies in a target-oriented manner,” Scheurer says.

The hybrid rocket motor is expected to perform its first maiden flight in July.

Related Content

Automated robotic NDT enhances capabilities for composites

Kineco Kaman Composites India uses a bespoke Fill Accubot ultrasonic testing system to boost inspection efficiency and productivity.

Read MoreCIRA qualifies CMC structures for the reusable Space Rider

Italian team designs, builds and tests multiple large, complex thermal protection system structures made from patented ISiComp C/C-SiC ceramic matrix composites.

Read MoreComposite molding compound replaces Invar for lightweight small satellite structures

Patz Materials and Technologies and Lawrence Livermore National Laboratory developed a new monolithic optics housing with 80% less weight, near-zero CTE and the high-volume manufacturing required for commercial space.

Read MoreOptimizing a CFRP landing leg demonstrator

MT Aerospace achieves design for manufacturing, integrating multiple elements into one-piece structure using AFP and 3D printed tooling to meet time and budget constraints.

Read MoreRead Next

Autonomous agricultural robot supported by composite components

3D-printed carbon fiber-filled composite components enable a robotic weeding system prototype intended to replace use of chemical herbicides.

Read MoreUltrasonic welding for in-space manufacturing of CFRTP

Agile Ultrasonics and NASA trial robotic-compatible carbon fiber-reinforced thermoplastic ultrasonic welding technology for space structures.

Read MoreCutting 100 pounds, certification time for the X-59 nose cone

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.

Read More