Researchers develop scalable graphene production method for industrialization opportunities

Semi-automated, in-line process, which addresses high startup and labor costs, is considered essential in scaling for commercial applications, showing potential for fiber reinforcement and printed sensors.

Optical image inkjet-printed transistor contacts (left) and interconnect (right). The scale bar is 100 micrometers (left) and 1 centimeter (right). Photo Credit, all images: “”

Researchers at the (AMBER, Dublin, Ireland) and Trinity’s School of Physics (Dublin), alongside colleagues at the Cambridge Graphene Centre (U.K.), University of Cambridge, Newcastle University and the University of Stavanger (Norway) have announced the development of a next-generation, low-cost scalable production method for graphene in the . Research suggestions that the process could substantially reduce graphene production costs to ~£20 (~$27) per liter once scaled, and produce multi-tonne quantities if successfully commercialized, far exceeding the current global graphene supply (~one kilotonne). This could potentially aid in accererating the adoption of graphene to industry and encourage graphene manufacturers that have previously been hampered by high capital equipment and labor costs.

Graphene and other atomically thin “2D materials” are expected to find major commercial applications in the coming years as a result of distinctive electrical, optical, mechanical, chemical and thermal properties. Graphene can be used as a barrier material for anti-corrosion, an additive for mechanical reinforcement in polymers or as a conductive material in sensors. According to researchers, these applications will require high-quality, defect-free graphene supplied in quantities exceeding current supplies at lower costs.

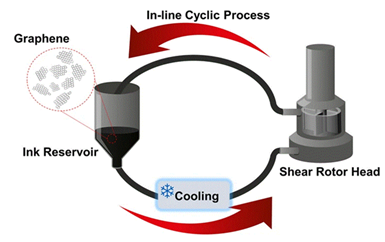

The research team’s approach is based on the graphite exfoliation process — a bulk method for producing graphene from graphite. They have found a novel, low-turbulence, semi-automated process through engineering the fluid dynamics to exfoliate graphene flakes from graphite with minimal defects. The method not only produces high-quality graphene ‘flakes’ suitable for industrial commercialization — and ideal for applications requiring high conductivity — but is a low-cost, in-line and enclosed process that also recycles unused graphite, ensuring high efficiency.

Schematic of the novel in-line process. Graphite, deionized water and SDC stabilization agent are added to the reservoir. The shear rotor head pushes the material around the system while generating shear force, enabling the exfoliation of graphite into graphene.

Building on this approach, the team created high-quality graphene inks and used household ink-jet printers to make conductive interconnects and lithium-ion battery anode composites that could potentially connect a battery to a textile sensor which could then be used to measure vital signs in the wearable health industry, amongst other applications. Given the applications in wearable electronics, textile electronics, composites and printed interconnects that could involve human contact with high concentrations of graphene, the team worked with colleagues at the University of Stavanger to determine the biocompatibility of the graphene inks. Repeated measurements showed no acute toxicity found when using the highest concentration of graphene in 48h cell culture treatments.

“We have demonstrated energy storage composites and printed electronic components in our work, however, there are many more applications that could be achieved with the graphene inks, such as [fiber]-reinforced composites or printed sensors,” says the research’s lead author, Dr. Tian Carey, who suggests this is just the start. “Also, graphene is just one example of a conductive 2D material; there are hundreds other lesser-known 2D materials which have different but complementary electronic behavior that we can apply this process to and create a suite of inks with different but complementary properties.”

“About ten years ago, I pioneered a simple method of making graphene from graphite through exfoliation in a household kitchen blender that has since been scaled and commercialized,” adds Prof. Jonathon Coleman, commenting on his team and collaborators’ success. “In this work, we have adapted the method further for industrial application and shown we can produce high-quality graphene at low cost in a highly efficient manner that is easily scalable.”

The study was funded by Science Foundation Ireland, a Marie SkÅ‚odowska-Curie Action Individual fellowship “MOVE,” and supported by the Engineering and Physical Sciences Research Council (EPSRC), in the U.K.

Read the .

Related Content

Mito to introduce graphene to EV energy storage innovations

Project initiatives for a multifunctional adhesive and addressing EV battery challenges are expected to change the dynamics of energy storage adoption.

Read MoreMito Materials graphene amplify composite fly fishing rod performance

Functionalized graphene addition to premium-performance Evos and Evos Salt fly rods by St. Croix Fly enables faster recovery, increased torsional rigidity and improved strength-to-weight ratios.

Read MoreComposites end markets: Batteries and fuel cells (2024)

As the number of battery and fuel cell electric vehicles (EVs) grows, so do the opportunities for composites in battery enclosures and components for fuel cells.

Read MoreCygnet, Viritech recover H2 tank continuous carbon fibers in Ford FCVGen2.0 project

Partner technologies have demonstrated the viability of recycled continuous fibers and the potential for automotive tanks to be recycled at meaningful rates.

Read MoreRead Next

Assembling the Multifunctional Fuselage Demonstrator: The final welds

Building the all-thermoplastic composite fuselage demonstrator comes to an end with continuous ultrasonic welding of the RH longitudinal fuselage joint and resistance welding for coupling of the fuselage frames across the upper and lower halves.

Read MoreComposites end markets: New space (2025)

Composite materials — with their unmatched strength-to-weight ratio, durability in extreme environments and design versatility — are at the heart of innovations in satellites, propulsion systems and lunar exploration vehicles, propelling the space economy toward a $1.8 trillion future.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More