RAMPF TFP machine designs lightweight, cost-competitive complex composite parts

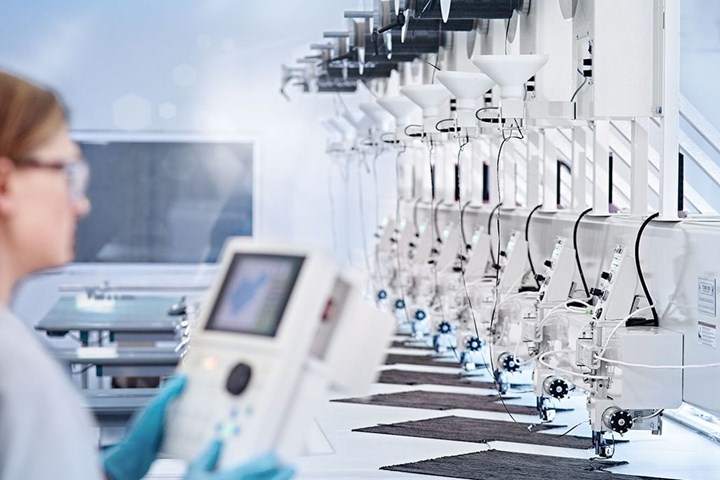

Eight-head Tailored Fiber Placement machine selectively places and orients composite filaments where strength or weight optimization is required.

Photo Credit: RAMPF Composite Solutions

RAMPF Composite Solutions (Burlington, Ontario, Canada) recently reported that it has reduced production cost and lowered component in complex composite parts with its new, eight-head Tailored Fiber Placement (TFP) machine.

RAMPF says this is achieved through TFP’s unparalleled freedom to selectively place and orient carbon fiber and glass fiber filaments where strength or weight optimization is required, thus maximizing the composite’s structural performance while providing for greater potential for weight savings, reduced carbon fiber usage and lower cost.

In a recent TFP success story, RAMPF Composite Solutions says it transformed a stainless steel part used in commercial aircraft to a part made almost entirely of carbon fiber. The resulting part is said to have weighed four-and-a-half times less without an increase in cost. In fact, the customer was able to realize additional operational cost savings because of the significant weight reduction. Furthermore, RAMPF says only five layup preforms were produced compared to the 75 that would have been required using traditional carbon fiber composite design approaches.

“Reducing production cost while lowering component weight in complex composite parts has often proved to be a mutually exclusive challenge,” says Larry Fitzgerald, CEO of RAMPF Composite Solutions. “Now, thanks to this technology and the composites design skills of our team, the advantages of TFP can be used to design complex parts to be lightweight and cost-competitive at the same time.”

Related Content

-

ZEBRA project demonstrates closed-loop wind recycling system

Consortium partners have proven the complete recycling of thermoplastic wind turbines via two manufactured wind blades, featuring reduced operating cost, CO2 emissions.

-

Aviation-specific battery system uses advanced composites to address electric, hybrid flight

BOLDair’s composite enclosure, compression structures and thermal runaway management enables high-performance electric energy storage.

-

High-tension, vertical filament winding enables affordable flywheel energy storage system

French startup Energiestro’s prototype solar energy flywheel-based storage system aims to reduce costs with glass fiber composites and prestressed concrete.