National Composites Centre joins new digital series to explore advances in sustainable materials

“Material Change: Resourcing Net Zero” campaign highlights critical role of composites in a net-zero future.

Share

ARC Marine’s low-carbon composite rope, developed in collaboration with the NCC. Photo Credit: ARC Marine.

The National Composites Centre (NCC, Bristol, U.K.) announces that it is taking part in a new digital series, , which is exploring expertise and advances throughout the materials cycle to address the climate crisis, achieve net-zero targets and accelerate the circular economy.

Launched at an event with senior policymakers in London in October 2022, the Institute of Materials, Minerals and Mining (IOM3) led series features commentary from a range of industry experts and stories from organizations who are driving innovation across exploration and extraction, processing and application, recycling, and repurposing and reuse. The NCC is one of a number of content partners involved in the campaign and is highlighting the vital role that composite materials play in the U.K.’s economic and sustainability ambitions.

“As the world-leading authority in advanced composites, we have a proven track record in helping companies of all sizes across the U.K. to innovate in composites development,” Kevin Mee, head of chief engineering at the NCC, says. “Composite materials are a disruptive technology that are crucial in our transition to net zero. The National Composites Centre’s focus on high-performance composites, with the underpinning development around sustainable, bio-derived materials, digital technologies and hydrogen provides a great vehicle to create new jobs and expertise, maintaining the U.K.’s leadership position for a sustainable future.”

The NCC, part of the UK’s , works with more than 200 SMEs every year who are looking to innovate and scale up their products, giving them access to world-class technologies and expert composites engineers.

This year, the company worked with , a small business based in Torquay, U.K., that develops nature-based solutions for the marine environment. ARC Marine needed a sustainable alternative to the plastic ropes it uses to secure its carbon-neutral marine matts that hold subsea pipes and cables on the seabed.

The NCC’s team of specialist engineers helped created a that can not only withstand the harsh sea environment but is kinder to marine wildlife — and could lead to a CO2 reduction of up to 88% when compared to a standard polypropylene (PP) rope, the company notes. The project is featured in the Material Change campaign as an example of the work undertaken with the U.K. industry that is driving the journey to a sustainable future.

“With each traditional mattress deployed, there’s an average of 140 meters of plastic rope that enters the ocean with it,” Tom Birbeck, co-founder and CEO of ARC Marine, says. “Marine plastics damage our seas by harming numerous sea creatures, including fish, cetaceans, turtles, seabirds, coral and even humans. Our plastic-free rope will undoubtedly change the face of the industry by preventing tonnes of plastic from entering the sea whilst enhancing marine ecosystems. That’s why we’re proud to have worked with the NCC to create it — they’ve been instrumental in developing and refining the design.”

More about the ARC Marine can be .

Related Content

Machina Labs unveils Machina Deployable System for agile manufacturing

Portable system combines AI and robotics for the forming and cutting of custom composite and metal parts.

Read MoreOn the radar: Composite materials producer ramps up sustainability vision

Toray is one of many companies in the composites industry fostering improvements in recyclability and biocomposites, as exemplified by its latest announcements.

Read MoreSchrödinger advances materials informatics for faster development of next-gen composites

Cutting time to market by multiple orders of magnitude, machine learning and physics-based approaches are combined to open new possibilities for innovations in biomaterials, fire-resistant composites, space applications, hydrogen tanks and more.

Read MoreAerotech Academy Puglia is inaugurated at Leonardo Aerospace site in Grottaglie, Italy

Joining the Leonardo MaTeRIA Lab and Joint Lab with Syensqo, this aerostructures training course will be 75% materials science and structural design/analysis, 25% digital transformation and AI.

Read MoreRead Next

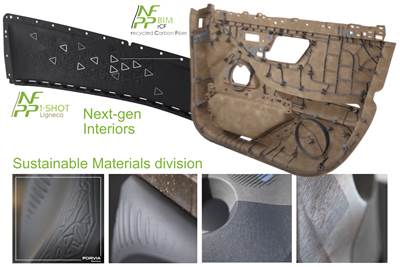

Faurecia advances biocomposites, recyclability, reduced CO2 and sustainability in automotive

Efforts include advancing NAFILean materials family in weight reduction and sustainability, as well as new Sustainable Materials division and R&D Center.

Read MoreNCC launches U.K. initiative to industrialize continuous carbon fiber reclamation

The NCC begins a three-year program to rapidly refine and scale industry continuous carbon fiber recycling, a key solution to net-zero ambitions. Partner collaborations are welcomed to the effort.

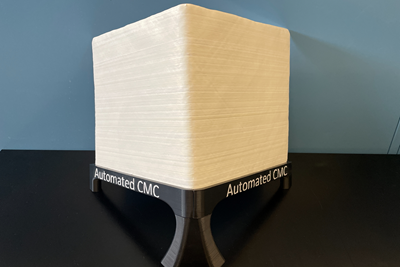

Read MoreNCC successfully demonstrates AFP manufacture of CMC parts

Core Research program adapts existing AFP technology and identifies optimal deposition parameters using a novel 3M towpreg material for wider CMC use.

Read More