NASA's Orion completes first spaceflight test

NASA's uncrewed Orion spacecraft completed its first voyage to space on Dec. 5, traveling farther than any spacecraft designed for astronauts has been in more than 40 years.

NASA marked a major milestone on Dec. 5 on its journey to Mars as the Orion spacecraft completed its first voyage to space, traveling farther than any spacecraft designed for astronauts has been in more than 40 years.

“Today’s flight test of Orion is a huge step for NASA and a really critical part of our work to pioneer deep space on our Journey to Mars,” said NASA administrator Charles Bolden. “The teams did a tremendous job putting Orion through its paces in the real environment it will endure as we push the boundary of human exploration in the coming years.”

Orion flew into the morning sky at 7:05 a.m. EST, lifting off from Space Launch Complex 37 at Cape Canaveral Air Force Station in Florida on a United Launch Alliance Delta IV Heavy rocket. The Orion crew module splashed down approximately 4.5 hours later in the Pacific Ocean, 600 miles southwest of San Diego, CA, US.

During the uncrewed test, Orion traveled twice through the Van Allen belt where it experienced high periods of radiation, and reached an altitude of 5,793 km above Earth. Orion also hit speeds of 20,000 mph and weathered temperatures approaching 2,204°C as it entered Earth’s atmosphere.

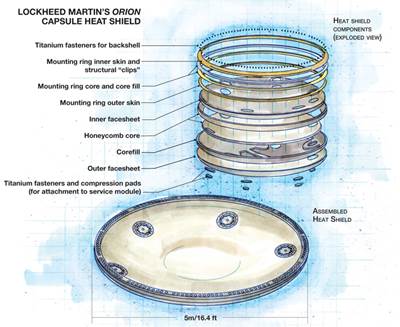

Orion will open the space between Earth and Mars for exploration by astronauts. This proving ground will be valuable for testing capabilities future human Mars missions will need. The spacecraft was tested in space to allow engineers to collect critical data to evaluate its performance and improve its design. The flight tested Orion’s composites heat shield (see link at right for details), avionics, parachutes, computers and key spacecraft separation events, exercising many of the systems critical to the safety of astronauts who will travel in Orion.

On future missions, Orion will launch on NASA’s Space Launch System (SLS) heavylift rocket currently being developed at the agency’s Marshall Space Flight Center in Huntsville, AL, US. A 70 metric-ton SLS will send Orion to a distant retrograde orbit around the moon on Exploration Mission1 in the first test of the fully integrated Orion and SLS system.

“We really pushed Orion as much as we could to give us real data that we can use to improve Orion’s design going forward,” says Mark Geyer, Orion program manager. “In the coming weeks and months we’ll be taking a look at that invaluable information and applying lessons learned to the next Orion spacecraft already in production for the first mission atop the Space Launch System rocket.”

A team of NASA, U.S. Navy and Lockheed Martin personnel aboard the USS Anchorage recovered Orion and will returned it to U.S. Naval Base San Diego. Orion will then be delivered to NASA’s Kennedy Space Center in Florida, where it will be processed. The crew module will be refurbished for use in Ascent Abort2 in 2018, a test of Orion’s launch abort system.

Lockheed Martin, NASA’s prime contractor for Orion, began manufacturing the Orion crew module in 2011 and delivered it in July 2012 to the Neil Armstrong Operations & Checkout Facility at Kennedy where final assembly, integration and testing were completed. More than 1,000 companies across the country manufactured or contributed elements to Orion.

Related Content

Low-cost, efficient CFRP anisogrid lattice structures

CIRA uses patented parallel winding, dry fiber, silicone tooling and resin infusion to cut labor for lightweight, heavily loaded space applications.

Read MoreOptimizing a CFRP landing leg demonstrator

MT Aerospace achieves design for manufacturing, integrating multiple elements into one-piece structure using AFP and 3D printed tooling to meet time and budget constraints.

Read MoreNASA launches composite solar sail into space

Sunlight-based propulsion system, supported by carbon fiber-reinforced booms, will undergo weeks-long testing to demonstrate and verify its capabilities.

Read MoreComposites end markets: New space (2025)

Composite materials — with their unmatched strength-to-weight ratio, durability in extreme environments and design versatility — are at the heart of innovations in satellites, propulsion systems and lunar exploration vehicles, propelling the space economy toward a $1.8 trillion future.

Read MoreRead Next

Orion re-entry system: Composites displace metal

World’s largest heat shield updates metal design with out-of-autoclave process.

Read MoreScaling up, optimizing the flax fiber composite camper

Greenlander’s Sherpa RV cab, which is largely constructed from flax fiber/bio-epoxy sandwich panels, nears commercial production readiness and next-generation scale-up.

Read MoreCutting 100 pounds, certification time for the X-59 nose cone

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.

Read More