NanoSperse celebrates 15 years of aerospace composites service

The Ohio-based business is dedicated to improving the durability, reliability and functionality of composites using nanotechnology for major U.S. aerospace and defense companies.

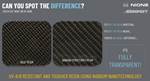

Tooling surfaces for additive tooling provide repairability and improved CTE stability. Source (All Images) | NanoSperse

NanoSperse (Kettering, Ohio, U.S.), a privately held, management-owned small business dedicated to the design, development and manufacturing of advanced composites, is celebrating 15 years of service to the aerospace community.

Supported by Air Force ManTech funding, NanoSperse opened its 20,000-square-foot facility in Kettering (Dayton), Ohio, in 2009. Since then, the company has transitioned innovative erosion coatings for Air Force and Navy aircraft, specialized conductive adhesives for spacecraft and qualified novel radius filler technology for use in production of stringers for next-generation aircraft composite wings and other primary and secondary structures. The company is developing novel consolidated discontinuous epoxy compounds for use as tooling surfaces for 3D printed tooling, composite compounds for molded parts with complex features and low-cost compression moldable structures for unmanned systems.

Recently, the company has demonstrated lightweight radiation shielding materials for spacecraft applications and has received Air Force funding to mature and transition the technology for spacecraft.

From inception, the company has registered design development and manufacturing operations to AS9100 quality standards, demonstrating its commitment to meeting the stringent standards demanded by its customer base. Customers include many of the major U.S. aerospace and defense companies. Its day-to-day activities center around design and development for specific customer requirements while providing a rapid transition pathway for material innovations that deliver competitive advantage to the customer, including setting up cost-effective production capabilities dedicated to specific needs.

Related Content

-

“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

-

Near-zero erosion ultra-high temperature CMC

K3RX commercializes UHTCMC for a wide range of markets, demonstrating performance in prototypes, assemblies and advancing manufacturing to reduce cost.

-

Orbital Composites wins AFWERX award for Starfighter drone fleet

Under the TACFI contract, Orbital is implementing the AMCM process to build 3D printed composite multi-mission UAS aircraft, surpassing $10 million in government awards.