Mito Material Solutions cuts ribbon on new facility in Indianapolis

The graphene additive developer, which serves sporting goods and other composites markets, grows its capabilities with a new facility that includes in-house R&D and testing space.

The Mito Materials Solutions team cut the ribbon on their new Indianapolis-based headquarters on Aug. 24, 2022. Photo Credit: CW

On Wednesday, Aug. 24, Mito Material Solutions (Indianapolis, Ind., U.S.) held a ribbon-cutting ceremony and open house to celebrate the recent opening of its new headquarters in Indianapolis.

The company, originally started in Oklahoma, develops additives to enhance performance of composites and plastics, including its flagship graphene oxide-based additive E-GO.

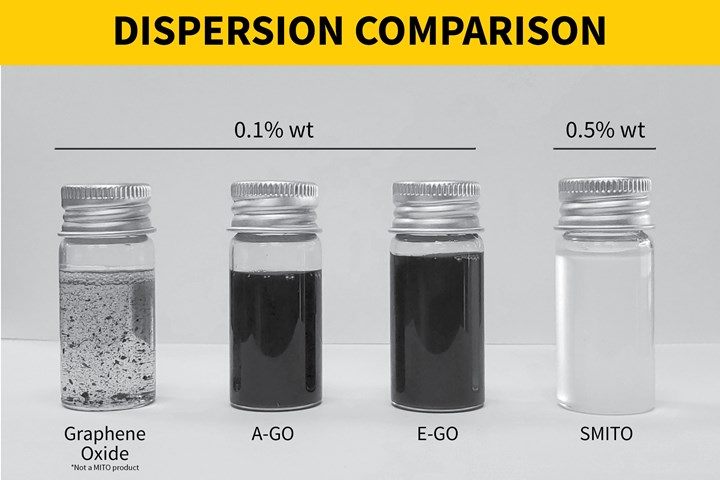

Within composites, Mito’s E-GO product is used to decrease weight and increase mechanical properties such as strength, electrical conductivity and thermal conductivity in composite sporting goods applications such as skis and fishing rods. E-GO and Mito’s other additives can be dispersed directly into a resin in amounts as small as 0.1% concentration for composites fabrication, or come in a spray format to be applied to a prepreg.

To answer your questions, the new building is 7,000 sq ft and we currently have a FT team of 7 and 4 PT remote team members bringing our total size to 11 with 6 open FT positions and internship opportunities available.

At the new, 7,000 square-foot facility, Mito houses its staff offices, commercial-scale graphene functionalization and dispersion equipment, an R&D laboratory with where the company can fabricate sample parts with its materials and an in-house analytical room for testing material properties. The R&D lab includes capabilities for hand layup, vacuum infusion and waterjet cutting with more equipment to come, and the testing room includes equipment to test a sample part’s flexure and tensile strength, interlaminar toughness, compression strength, as well as thermal, electrical and vibrational properties.

Mito’s team now includes 7 full-time and 4 part-time remote team members, with full-time and internship opportunities available.

Speakers at the Aug. 24 ribbon-cutting event included Haley Keith, CEO of Mito Material Solutions, as well as partners Kip Frey, executive VP of new ventures at The Heritage Group (Indianapolis); Julie Heath, VP of entrepreneurial ecosystems at the Indiana Economic Development Corp. (Indianapolis); Dale Brosius, interim CEO of IACMI (Knoxville, Tenn., U.S.); and Keith Blakely, chairman and CEO of OnCore Golf Technology Inc. (Buffalo, N.Y., U.S.).

“We want to celebrate our journey so far and also what’s to come,” Keith said at the event. “Our products don’t just exist in the lab; we have the ability to solve a wide variety of problems and provide solutions that redefine what’s possible.”

Mito Materials, led by husband and wife team Haley Keith and CTO Kevin Keith, began as a startup in 2015 based on nano-additive technology developed by Oklahoma State University and research funded by the National Science Foundation (NSF). The company went through Heritage Group’s Accelerator program, and earlier this year raised $4.5 million in a funding round that closed in January 2022.

The move to Indiana brings the company closer to several of its partners and potential composites industry leaders. “In Indiana, there are a lot of opportunities to connect with composites companies and real opportunity to serve in new areas like EV battery boxes, hydrogen storage tanks especially cryogenic liquid hydrogen storage, wind turbines and more,” Brosius said at the event.

Looking to the future, the company plans to move into new composites markets and is currently aiming to grow its team, with six open positions.

Related Content

Bladder-assisted compression molding derivative produces complex, autoclave-quality automotive parts

HP Composites’ AirPower technology enables high-rate CFRP roof production with 50% energy savings for the Maserati MC20.

Read MorePlant tour: Teijin Carbon America Inc., Greenwood, S.C., U.S.

In 2018, Teijin broke ground on a facility that is reportedly the largest capacity carbon fiber line currently in existence. The line has been fully functional for nearly two years and has plenty of room for expansion.

Read MoreRevisiting the OceanGate Titan disaster

A year has passed since the tragic loss of the Titan submersible that claimed the lives of five people. What lessons have been learned from the disaster?

Read MoreCombining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

Read MoreRead Next

Cutting 100 pounds, certification time for the X-59 nose cone

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.

Read MoreNext-gen fan blades: Hybrid twin RTM, printed sensors, laser shock disassembly

MORPHO project demonstrates blade with 20% faster RTM cure cycle, uses AI-based monitoring for improved maintenance/life cycle management and proves laser shock disassembly for recycling.

Read MoreCeramic matrix composites: Faster, cheaper, higher temperature

New players proliferate, increasing CMC materials and manufacturing capacity, novel processes and automation to meet demand for higher part volumes and performance.

Read More.jpg;width=70;height=70;mode=crop)