Markforged, MSC Software partner on 3D printer simulation tools

Customers will have increased access to MSC’s process simulation, performance modeling and material analysis tools for Markforged 3D printers.

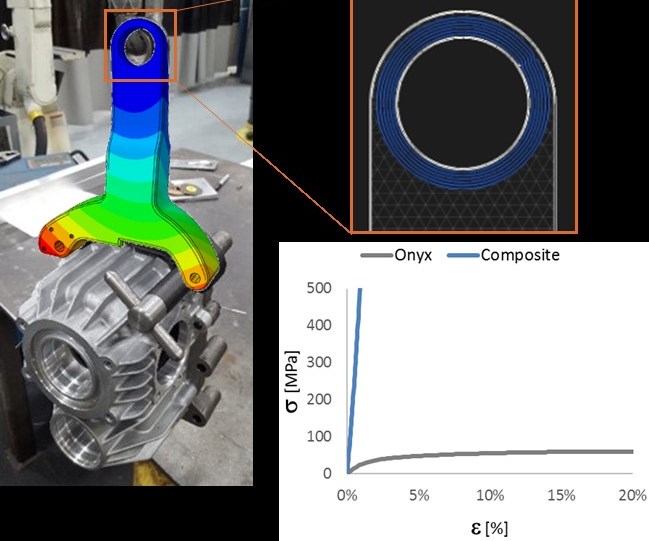

A test part is overlaid with part performance modeled virtually with Digimat, using material definitions for the exact print materials. Source | MSC Software Corp.

Markforged (Cambridge, Mass., U.S.), a leading provider of metal and carbon fiber 3D printers, and MSC Software Corp. (MSC, Newport Beach, Calif., U.S.), a global leader in computer-aided engineering (CAE) simulation software and services, have announced a technology partnership to deliver process simulation, performance modeling and material analysis tools for Markforged 3D printers.

Customers have already been able to implement material analysis for Markforged continuous carbon fiber and Onyx materials within MSC’s Digimat materials modelling software. The new collaboration will provide full-process simulation and part performance with finite element analysis (FEA) within a common CAE environment. MSC and Markforged clients can access digital material cards that capture the mechanical and material properties of Markforged’s continuous fibers and chopped fiber-filled plastics.

With new process simulation features, clients will be able to model 3D printing within the MSC software, Markforged says. They will also be able to establish print calibration standards, ensure each machine is optimized for the part, and make sure each part is printed accurately the first time. To improve part performance, customers will be able to connect the Markforged material and print information with FEA simulation from MSC. They can run simulations on proposed designs containing continuous fibers and printed thermoform plastics to predict the parts’ mechanical and structural performance.

“3D printing is transforming the factory floor, and with MSC as our partner, we can ensure all parts made with Markforged will perform at their peak potential,” says Jon Reilly, VP of product at Markforged.

“Markforged is a pioneer in the 3D printing space, and its continuous carbon fiber material is so strong, it’s replacing aluminum in factories across the globe,” says Olivier Lietaer, business development engineer for additive manufacturing at e-Xstream Engineering, part of MSC. “This shift in design and manufacturing requires new analysis capabilities that can validate customer designs with the same confidence as traditionally manufactured parts. Because it applies data specific to printing conditions, Digimat gives customers 100% confidence that their part designs can be 3D-printed, making additive manufacturing accessible to applications that require rigorous testing. Together, Markforged and MSC enable customers to guarantee the performance of a part from its material properties through to final part strength and weight.”

Danfoss Power Solutions (Ames, Iowa, U.S.), a global provider of mobile hydraulics and hydraulic, electronic and electrical solutions for various markets, printed a lifting bracket with Markforged to lift cast housings in an assembly process. Given the suspended loads and the proximity of workers, validation is needed to ensure safe working conditions. With MSC and Markforged’s partnership, the simulation workflow has been validated on the bracket and the failure area has been identified, Markforged says. The company reports that the results show a significant safety margin that validates that the lifting bracket can be safely deployed in operations and further offers an opportunity to reduce mass and cost.

“The company’s partnership with MSC will not only demonstrate that their composite parts can replace metal, but also help identify a part's top potential. Simulating the ideal weight, ideal cost savings, and ideal lead times with MSC will help us reduce our time and material usage so we can just print and deploy,” says Jeff Herrin, VP of research and development at Danfoss Power Solutions.

Related Content

Active core molding: A new way to make composite parts

Koridion expandable material is combined with induction-heated molds to make high-quality, complex-shaped parts in minutes with 40% less material and 90% less energy, unlocking new possibilities in design and production.

Read MoreCombining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

Read MoreCarbon fiber composite pallet revolutionizes freight industry

LOG Point Pallet fuses advanced materials with innovative design and manufacturing to improve supply chains worldwide.

Read MoreComposites end markets: New space (2025)

Composite materials — with their unmatched strength-to-weight ratio, durability in extreme environments and design versatility — are at the heart of innovations in satellites, propulsion systems and lunar exploration vehicles, propelling the space economy toward a $1.8 trillion future.

Read MoreRead Next

New Digimat 2019.1 release enables smarter fiber-reinforced composite design values, allowables and crash modeling

Upgrades include high fiber content virtual test with 10-100 times faster analyses and progressive damage analysis using the Camanho method.

Read MoreCutting 100 pounds, certification time for the X-59 nose cone

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.

Read MoreNext-gen fan blades: Hybrid twin RTM, printed sensors, laser shock disassembly

MORPHO project demonstrates blade with 20% faster RTM cure cycle, uses AI-based monitoring for improved maintenance/life cycle management and proves laser shock disassembly for recycling.

Read More.jpg;width=70;height=70;mode=crop)