Lilium selects Aciturri for eVTOL fabrication

Spain-based Tier 1 aerospace manufacturer Aciturri will fabricate all composite and metallic structures for the piloted, four-passenger eVTOL Lilium Jet.

Lilium Jet rendering. Photo Credit: Lilium

Lilium (Munich, Germany), the aviation company developing an all-electric, vertical take-off and landing (eVTOL) aircraft and service for regional air mobility, and aerospace fabricator (Miranda de Ebro, Spain), on Feb. 23 announced a long-term partnership to fabricate composite and metallic structures of the airframe for the Lilium Jet.

Lilium Jet is a piloted, fixed-wing eVTOL air taxi with seating for up to four passengers. It is powered by 36 tilting ducted fans mounted on the leading edge of each wing and the horizontal tail fin. It’s designed for intercity service and has a range of 300 kilometers/186 miles and a maximum speed of 300 kph/186 mph.

The partnership follows a competitive procurement process and is a significant step towards prototyping for serial production of the Lilium Jet. The agreement also marks a new growth segment for Aciturri, which is already established in the commercial aerospace supply chain, manufacturing major airframe components for Airbus, Boeing, and Embraer.

Rendering of Lilium Jet landing at a vertiport. Photo Credit: Lilium

Aciturri will handle the production of the Lilium Jet’s primary composite structures, which will use materials supplied by Toray Industries (Tokyo, Japan), with whom Lilium signed an agreement for the supply of high-performance carbon fiber composite materials in May 2020.

Yves Yemsi, chief program officer at Lilium, says, “During my 16 years at Airbus, I became well acquainted with Aciturri’s capabilities in producing complex composite structures for commercial aircraft to exacting quality standards. Few companies in the world have mastered designing and manufacturing aerospace composite structures like Aciturri. It is for this reason that the company is an ideal partner for Lilium as we continue our strategy of working with the best Tier 1 aerospace suppliers.”

Yemsi, who is a veteran of the composites-intensive Airbus A350 program, tells CW that design of Lilium Jet is still being finalized, but that Aciturri will soon begin fabrication of structures for the first pre-production prototype. That fabrication, he says, will rely on use of qualified, conventional, hand-laid, autoclave-cured carbon fiber prepregs to “de-risk the manufacturing process and allow dynamic changes” as the plane enters low-rate production.

Eventually, however, over the next five or so years, the Lilium Jet will enter full-rate production, and the use of hand layup will not be sufficient to meet volume requirements. Yemsi says this transition will necessitate evolution to automated fiber placement (AFP) and other automation, and eventually potential use of out-of-autoclave materials, including thermoplastics. It’s this evolution of materials and processes that, in part, drove the selection of Aciturri as a partner, Yemsi says: “We will have the best manufacturing technology and capabilities for our next steps.”

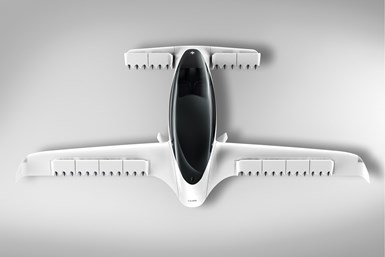

Lilium Jet front view. Photo Credit: Lilium

At the moment, however, Yemsi emphasizes that Lilium’s efforts are trained on finalizing a manufacturable design. “My focus right now is on a robust process to come to market with a very robust design. Lilium has a highly robust engineering environment doing robust trade-off assessments to meet weight and safety targets. Our focus is on the requirements of certification.”

Vincente Brisa, commercial director for Aciturri, says Lilium first engaged with Aciturri at the 2019 Paris Air Show, so this announcement is the culmination of two years of groundwork laid. He notes that, in light of the pandemic-caused downturn in commercial air travel, “this is great news in a very bad situation. Lilium represents an opportunity for new activity and we are very excited.”

Brisa echoed Yemsi’s comments regarding use of hand-laid prepregs early in the Lilium Jet program. “Well-proved and renowned materials and processes is the best way to do this, but other materials and processes are on the table, depending on qualification requirements.” Brisa says Aciturri expects to deliver Lilium Jet prototype structures to Lilium in 2022, followed by low-rate production. He estimates that Aciturri can produce shipsets for several hundred Lilium Jets per year using hand-laid prepregs. Beyond that, he says, other materials and processes must be considered.

Lilium Jet top view. Photo Credit: Lilium

Most of the composites fabrication for the Lilium Jet, says Brisa, will be performed at Aciturri’s facility in Boecillo, Spain, with other Aciturri facilities contributing manufacturing services, including metals fabrication, as needed. The Boecillo plant has three autoclaves, three cleanrooms, automated cutting capabilities, AFP/ATL capabilities and employs about 200 people.

Alvaro Fernandez Baragaño, CEO at Aciturri, says of the Lilium partnership, “We have long sought innovation in all that we do, and Lilium is no exception. We look forward to building this special relationship to support Lilium in achieving their vision of bringing this unique aircraft to life. This long-term partnership allows us to work collaboratively with Lilium through its early operational years, and beyond, throughout which we will continue to explore new methods and advanced technologies which our advanced techniques are capable of achieving, to ensure production of the highest quality and at growing scale.”

Related Content

Prepreg compression molding supports higher-rate propeller manufacturing

To meet increasing UAV market demands, Mejzlik Propellers has added a higher-rate compression molding line to its custom CFRP propeller capabilities.

Read MoreComposite Integration presents webinar on liquid resin infusion

On July 30, 2025, company experts will discuss the role of LRI in delivering scalable, OOA composite production for the aerospace sector.

Read MoreComposite resins price change report

CW’s running summary of resin price change announcements from major material suppliers that serve the composites manufacturing industry.

Read MoreCOMPINNOV TP2 project promotes use of thermoplastics in aerospace

Completed in 2023, COMPINNOV TP2 explored thermoplastic composites, enhancing the understanding between prepregs and production methods to foster the potential for French aerospace innovation.

Read MoreRead Next

Ceramic matrix composites: Faster, cheaper, higher temperature

New players proliferate, increasing CMC materials and manufacturing capacity, novel processes and automation to meet demand for higher part volumes and performance.

Read MoreUltrasonic welding for in-space manufacturing of CFRTP

Agile Ultrasonics and NASA trial robotic-compatible carbon fiber-reinforced thermoplastic ultrasonic welding technology for space structures.

Read MoreNext-gen fan blades: Hybrid twin RTM, printed sensors, laser shock disassembly

MORPHO project demonstrates blade with 20% faster RTM cure cycle, uses AI-based monitoring for improved maintenance/life cycle management and proves laser shock disassembly for recycling.

Read More