Lanxess Tepex composite material lightweights luxury sedan load compartment well

PA6 Tepex dynalite thermoplastic blank reinforced with continuous glass fiber fabrics withstands high mechanical stresses and achieve 30% lighter weight than comparable sheet metal components.

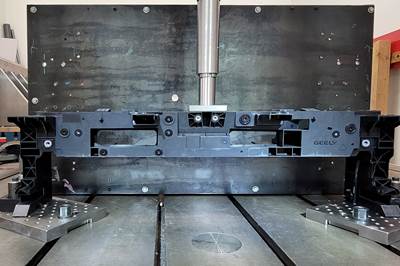

The load compartment well can withstand high mechanical stresses and is around 30% lighter than comparable sheet metal designs. Photo Credit: Lanxess

Lanxess (Cologne, Germany) has applied its Tepex dynalite continuous fiber-reinforced thermoplastic composite materials in the manufacture of the load compartment well installed in the Mercedes-Benz S-Class luxury sedan to accommodate the vehicle’s 48V on-board powder supply battery. Lanxess says the composite components can withstand high mechanical stresses and are around 30% lighter than comparable sheet metal components.

“In the event of a crash, the battery must not penetrate or in any way damage the recess wall. This is ensured by the high strength and stiffness of our fabric-based composite material,” says Dr. Klaus Vonberg, application expert for Tepex at Lanxess. “The composite design also ensures that the load compartment well is leaktight, preventing the ingress and egress of fluids like water and battery electrolyte.”

The safety component is manufactured in a hybrid molding process using a ~110 x 80-centimeter blank produced by a water cutting machine. The blank is made from polyamide 6 (PA6)-based Tepex dynalite 102-RG600(2), which is reinforced with two layers of continuous glass fiber-reinforced fabrics. Moreover, Lanxess’ PA6 Durethan BKV60H2.0EFDUS060 is used as a back-injection material to integrate fasteners and reinforce the ribs. Sixty percent of its mass comprises short glass fibers, says Lanxess, which also optimizes its strength and stiffness for its use with the Tepex material.

Forming (draping) of the blank is then performed by a stamp, a highly complex process, among other things, the company says, due to the high draw ratios. This is because the composite material does not expand plastically like sheet metal but undergoes deformation in response to the movement (draping) of the fibrous material, which means that the composite material has to be continuously supplied from the outside during the forming process. If the movement is too great, the fibers can inhibit the forming process, breaking as a result and impacting the rest of the process.

Lanxess also employed a range of virtual calculation models, enabling the company to precisely simulate the draping process — including determining the optimum 3D cutting geometries of the blank and its forming behavior — to better predict and analyze the forming effects and respond accordingly.

“For the load compartment well, we also determined when the critical shearing angle of the fabric is reached during forming, where wrinkles form and where fibers start to break,” says Vonberg. “Our calculations and simulations also helped to ensure that the rounded corners of the component can withstand the expected loads.” The local orientation of the continuous fibers themselves in component areas with a pronounced 3D contour (e.g., in the rounded corners) was also simulated. This is a prerequisite for precisely predicting mechanical behavior in terms of integrative simulation. “All of this is part of our service offering under the HiAnt brand with which we supported our customers’ development experts in designing the load compartment well,” says Vonberg.

Looking to the future, Vonberg notes that Lanxess also sees potential in electric vehicles (EVs). “For safety devices, complete battery system housing or components for the stowage space are now available under the ‘hood’ — because our lightweight structural material is much lighter than metal and so helps to extend the range of EVs,” he concludes.

Related Content

Carbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.

Read MoreThermoplastic composites: Cracking the horizontal body panel nut

Versatile sandwich panel technology solves decades-long exterior automotive challenge.

Read MoreCo-molding SMC with braided glass fiber demonstrates truck bed potential

Prepreg co-molding compound by IDI Composites International and A&P Technology enables new geometries and levels of strength and resiliency for automotive, mobility.

Read MoreImproving carbon fiber SMC simulation for aerospace parts

Simutence and Engenuity demonstrate a virtual process chain enabling evaluation of process-induced fiber orientations for improved structural simulation and failure load prediction of a composite wing rib.

Read MoreRead Next

Lanxess thermoplastics lightweight Geely front end carrier component

Evaluated and tested by Lanxess, the high-modulus, high-flow PA6 material reinforced with 50% glass fiber achieves high stiffness and strength for the multi-component assembly.

Read MoreNext-gen fan blades: Hybrid twin RTM, printed sensors, laser shock disassembly

MORPHO project demonstrates blade with 20% faster RTM cure cycle, uses AI-based monitoring for improved maintenance/life cycle management and proves laser shock disassembly for recycling.

Read MoreScaling up, optimizing the flax fiber composite camper

Greenlander’s Sherpa RV cab, which is largely constructed from flax fiber/bio-epoxy sandwich panels, nears commercial production readiness and next-generation scale-up.

Read More