Kisling epoxy adhesive improves carbon fiber bonding performance in automotive applications

The 2K-Epoxy ergo 7440 offers the removal of the bond-line read-through, attain high temperature resistance, avoids contact corrosion and enables quick turnaround during production.

Kisling’s 2K-Epoxy adhesive ergo 7440 applied to the new Ferrari F488 Pista Spider. Photo Credit: Kisling

Swiss-based adhesives manufacturer, (Wetzikon), has reportedly added 2K-Epoxy ergo 7440 to its ergo product structural portfolio. The new structural adhesive product is said to improve the bonding performance of carbon fiber parts for a variety of applications in the automotive industry. Due to several of its advantageous features, Kisling says, it has aided the Italian sports car manufacturer Ferrari in solving a current adhesive issue for a new automobile development.

For example, Kisling contends that ergo 7440 provides almost invisible composite bonding by removing the bond-line read-through (BLRT) — a visible distortion of the substrate over a cured adhesive bond-line — due to low shrinkage capabilities. An almost-invisible glue line was additionally accomplished by the black coloring of the epoxy adhesive.

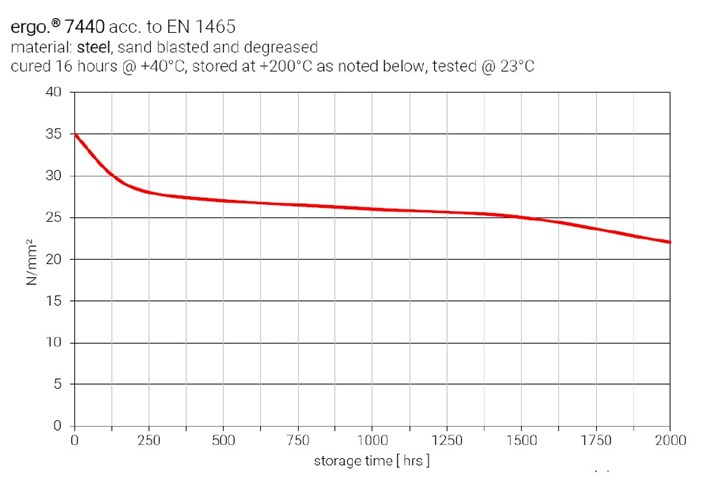

This product is also said to attain high temperature resistance of 180 °C. This performance criteria was proven by a 2,000-hour test. As can be seen from the graphic below, the Kisling ergo 7440 adhesive provides exceptionally high bonding strength after 2,000 hours of testing at 200 °C.

Photo Credit: Kisling

Further, a defined bonding gap is ensured via additives incorporated into the epoxy adhesive, avoiding contact corrosion in metal-carbon connections, and a 40-minute process time ensures that there is enough time for the bonding process, even with high ambient temperatures during the warmer months. Additionally, says Kisling, the ergo 7440 delivers a fast build-up of handling strength after 3.5 hours for quick turnaround during production.

Related Content

-

We4Ce infused 2.5-3-MW rotor blade design passes validation test

Composite rotor blade structure design by We4Ce, mold and prototype production by InDutch Composites and fatigue testing by Suzlon Group has resulted in the novel blade’s IEC61400-5:2020 certification.

-

Plant tour: Airbus, Illescas, Spain

Airbus’ Illescas facility, featuring highly automated composites processes for the A350 lower wing cover and one-piece Section 19 fuselage barrels, works toward production ramp-ups and next-generation aircraft.

-

JCB Aero aircraft interior flooring panels incorporate SHD composites

High-performance carbon fiber prepreg using SHD’s FRVC411 epoxy resin system resulted in a durable, compliant design for the MRO market.