JCB Aero aircraft interior flooring panels incorporate SHD composites

High-performance carbon fiber prepreg using SHD’s FRVC411 epoxy resin system resulted in a durable, compliant design for the MRO market.

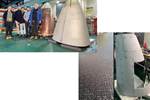

Panel kit equipped and ready to install. Source | SHD Composite Materials Ltd.

In collaboration with SHD Composites Materials (Sleaford, U.K.), (Auch, France) — a company specializing in VIP/aircraft cabin completion and refurbishment — have developed a floorboard panel system for the maintenance, repair and overhaul (MRO) that is reported to offer a substantial weight reduction. The system uses unidirectional (UD) carbon fiber prepreg reinforced with FRVC411, SHD’s toughened and flame-retardant epoxy resin system, which has ultimately improved the durability of the new floor panels while reducing weight and cost.

JCB Aero’s floorboard panel system is compliant with BMS4-17/20/23. Through their EASA-certified design (Part 21J), production (Part 21G) and EASA Part 145 capabilities, the panels can be installed on 95% of Boeing cabins variants including B737, B747 and B777.

Tested for full conformance with aircraft interiors standards, FRVC411 is a toughened, flame-retardant epoxy resin system designed to cure between 65-140°C, enabling flexibility in component manufacture for aircraft and rail interior applications. Use of UD carbon fiber prepreg increases the panel system’s durability.

JCB Aero, partnering with SHD, boasts significantly faster production times compared to traditional OEM floorboard manufacturing. Prepreg materials can be delivered in just 3 weeks, the company contends, allowing JCB Aero to create custom floorboards with multiple supplemental type certificates (STCs) in a short time frame.

“The team at SHD were easy to work with and provided a tailored solution at an attractive price,” Eric Cagnat, chief operating officer at JCB Aero, says. “As the FRVC411 is a versatile resin system, it helped to reduce processing times while maintaining our high-quality requirements. Overall, we were very impressed with the product and will return for future projects.”

Related Content

-

JEC World 2024 highlights: Thermoplastic composites, CMC and novel processes

CW senior technical editor Ginger Gardiner discusses some of the developments and demonstrators shown at the industry’s largest composites exhibition and conference.

-

Plant tour: Teijin Carbon America Inc., Greenwood, S.C., U.S.

In 2018, Teijin broke ground on a facility that is reportedly the largest capacity carbon fiber line currently in existence. The line has been fully functional for nearly two years and has plenty of room for expansion.

-

Otto Aviation launches Phantom 3500 business jet with all-composite airframe from Leonardo

Promising 60% less fuel burn and 90% less emissions using SAF, the super-laminar flow design with windowless fuselage will be built using RTM in Florida facility with certification slated for 2030.