Graphene used to extend rechargeable battery life

Researchers from Western University finds that adding a carbon-based graphene layer extends lithium-ion rechargeable battery life up to 50%.

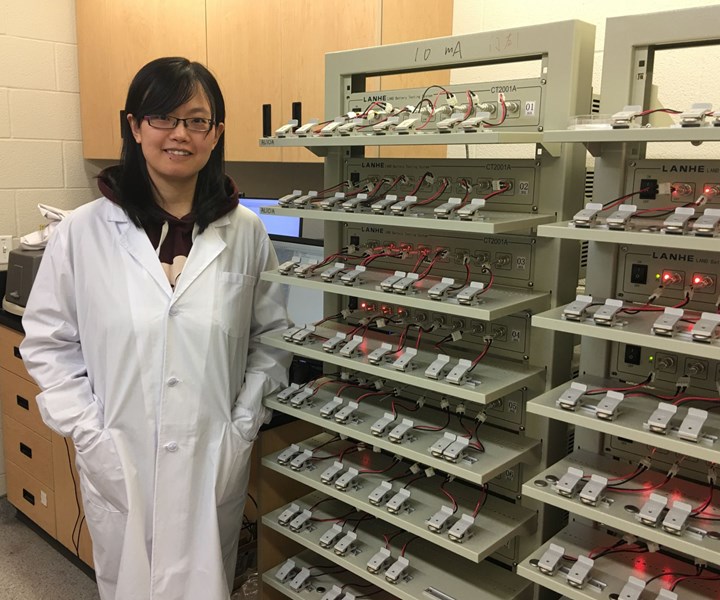

Xia Li, Mitacs Postdoc Fellow in Western’s Faculty of Engineering Source | Western Universityh

Researchers from Western University (London, Ontario, Canada), using the Canadian Light Source (CLS) — a synchotron powered light source — at the University of Saskatchewan (Saskatoon, Saskatchewan, Canada), has found that adding a carbon-based layer to lithium-ion rechargeable batteries extends their life up to 50%.

Aluminum foil is commonly used on the cathode as current collector where electricity leaves the battery of rechargeable lithium-ion batteries. This foil has high electronic conductivity and is lightweight and low cost, but the new generation of batteries brings new challenges to the current collectors, which will need even more chemical stability to protect against the corrosion of electrolyte in the cathode. Rather than find an entirely new material for cathodes, the Western team tested a super-thin carbon coating, also known as graphene, produced by (London, Ontario, Canada).

“We added a thin layer of carbon coating to the aluminum foil that conducts electric current in rechargeable batteries,” says Xia Li, a Mitacs postdoc fellow in Western’s Faculty of Engineering and lead researcher of the study. “It was a small change, but we found the carbon coating protected the aluminum foil from corrosion of electrolyte in both high voltage and high energy environments — boosting the battery capacities up to 50% more than batteries without the carbon coating.”

In addition to the graphene coating, 3M Canada supplied the CLS, which uses extremely bright X-rays to identify the chemical changes occuring on delicate battery surfaces as they are operating. Analysis showed that the carbon-based coating is effective in both high-voltage and high-energy environments, which would be important for applications like electric vehicles.

Related Content

-

Composites end markets: Automotive (2025)

Composites manufacturing intelligence drives circular economy solutions as automotive industry balances technical demands with sustainability mandates.

-

Moving toward sustainable automotive parts manufacturing

How can the automotive supply chain prepare for future sustainability requirements? Tier 1 Kautex Textron discusses emissions reduction, design for circularity and transition to recycled/bio-based plastics.

-

On the radar: Innovations in composite battery enclosures

A look at recently reported design, material and process innovations for composites-intensive battery enclosures, developed to support the ramp-up of EV and AAM vehicles.