Future Fibres’ LiMit Collar protects composite rigging against lightning

Multi-material system wins DAME Design Award 2023 for mitigating damage caused by direct or induced lightning currents to carbon fiber and metallic mast rigging for watercraft.

The LiMit Collar. Photo Credit, all images: Future Fibres

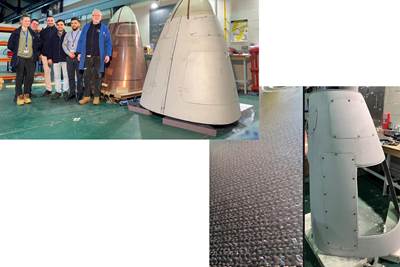

Composite rigging specialist (Valencia, Spain) has been named one of the winners of Mestrade’s DAME Design Awards 2023 under the “Security and Safety Aboard” category. Chosen as an example of a standout example of holistic design effort within the marine equipment sector, the company’s lightning mitigation system for carbon composite rigging (LiMit Collar) has proven a valid solution to protect composite rigging from the effects of lightning.

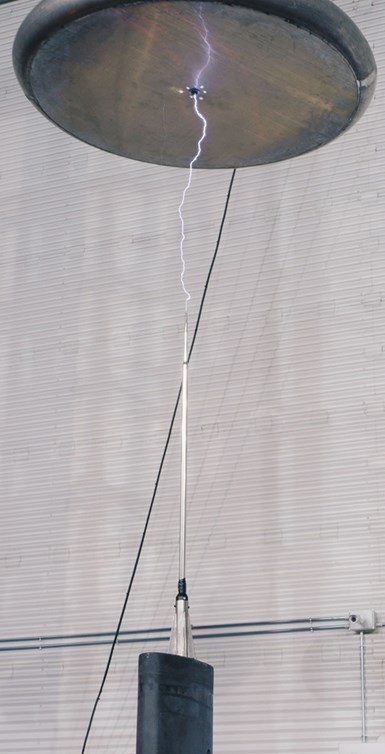

The LiMit Collar is a range of multistrand composite rigging products that are the result of a multiyear, €375K R&D program to better understand the issue of lightning strikes on masts. This included lightning strike testing under the most demanding aerospace standards with varying environmental conditions, as well as subsequent mechanical tests to understand the properties of the cables after a strike. Studies, which took place at the LCOE lab in Madrid, Spain, and Labelec lab in Barcelona, involved 350-plus strikes to develop rigging damage characterization and protection development, as well as spar interaction, current distribution and lightning protection systems.

Testing of the LiMit Collar (top) and a breakdown of its design (bottom).

“Even though carbon fiber is not a perfect conductive material (its conductivity is about 700 times lower than that of copper), it still can transmit electric current which means that in lightning events, the current can reach and spread across both metallic and composite structures,” Juanjo de la Cuesta, R&D manager at Future Fibres, explains. “Another reason why large composite rigs and stays are subject to lightning damage is because, apart from their relatively good conductivity, they have a reasonably large diameter, and as a result, significantly lower inductance compared to conventional metallic down conductors. Therefore, it is likely for the current to partially arc towards these structures and flow through the path with the overall lowest impedance. This, added to the fact that composites are normally sensitive to high temperatures like the ones that can take place during lightning arcing, for instance, highlights the necessity to include the lightning events in the design requirements of those structures that may be subjected to them.”

Composite rigging is typically composed of a carbon fiber core, epoxy resin cone ends and titanium end fittings. The LiMit Collars is designed as a multilayered and multi-material system — it has both conductive and insulating materials that prevents a lightning current from arcing from the carbon fiber core to the metallic terminals. Rather, the solution provides an alternative path for the current by absorbing the strike. Future Fibres says that when installed at each conical end fitting with a metallic interface connection of rigging, LiMit Collars have been capable of protecting sailing boats with carbon fiber spars up to 90 meters high, said to be the largest ever built. Moreover, use of LiMit Collars could translate to lower downtime (reduced need for inspections or repairs) and overall enhanced safety.

“In laboratory sessions, during the development of LiMit collars, it was observed how critical the transition point from the composite structure to the protective layer was, so composite materials were introduced to reinforce this area while still being a relatively good conductive element,” de la Cuesta explains. “Composite materials were used for this application due to their lightweight, relative conductivity and compatibility with the composite stays.”

As a result of the program, LiMit Collar is offered on all rigs for boats above 100 feet by default. Future Fibres is looking forward to bringing these findings to industry.

Related Content

Hybrid composite architecture enables rigid wind propulsion solution for maritime decarbonization

GT Wings’ AirWing leverages aerospace engineering principles combined with hybrid glass and carbon fiber composite construction to deliver up to 30% fuel savings through compact, deck-compatible wind propulsion.

Read MoreLarge-format AM speeds plug production for manufacture of composite boat molds

Hungarian manufacturer Rapid Prototyping transitioned its conventional foam milling process to 3D printing to produce faster, higher quality, recyclable foam plugs and composite boat molds.

Read MoreEuropean boatbuilders lead quest to build recyclable composite boats

Marine industry constituents are looking to take composite use one step further with the production of tough and recyclable recreational boats. Some are using new infusible thermoplastic resins.

Read MoreEvolving natural fiber technology to meet industry sustainability needs

From flax fiber composite boats to RV exterior panels to a circularity model with partnerships in various end markets, Greenboats strives toward its biomaterials and sustainable composites vision in an ever-changing market.

Read MoreRead Next

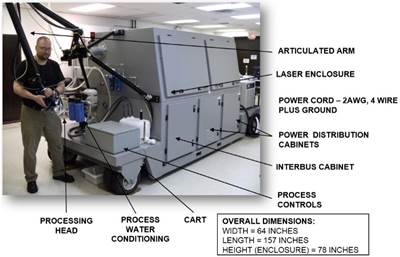

Laser bondline inspection becomes reality

One of the Holy Grails of composites manufacturing has been reliable verification of adhesive bondline strength integrity. A technology that does just that has arrived.

Read MoreD-JOINTS project helps engineers protect composite aircraft structures from lightning strikes

Design of innovative composite hybrid joints with electromagnetic compatibility project tested and validated two types of joint technologies plus software tool for faster design.

Read MoreAfter lightning strikes: Repair considerations

When lightning does strike, aircraft LSP system repairs must be done correctly to ensure restoration of protection.

Read More