Fill ACCUBOT spurs GKN Aerospace composite aircraft parts inspection

Flexible and precise multimodal robot system conducts quicker inspection processes, reducing GKN’s geometrical inspections from 11 hours to half an hour.

With two articulated robots on linear axes running in parallel, the ACCUBOT system from Fill can conduct non-destructive testing of composite components in three separate zones. All photo credit: P. Kemptner

Fill Gesellschaft m.b.H. (Gurten, Austria) announced on June 15 that the incorporation of its flexible and dynamic ACCUBOT (Accurate RoBot) multimodal robot system into GKN Aerospace’s (Redditch, U.K.) plant in Munich, Germany, which specializes in producing composite aircraft parts, enabled GKN to significantly increase the productivity and reliability of its non-destructive component testing (NDT).

As a leading supplier of components for the aircraft industry, GKN Aerospace produces aircraft parts exclusively from carbon fiber composite materials at its Munich plant. As aircraft components are safety-relevant, they are subject to the strictest quality requirements. GKN subjects 100% of the parts to an ultrasonic inspection in order to detect irregularities, such as inclusions of foreign matter, delamination or porosity. FILL reports that initial inspection times for NDT were as long as 100 minutes on the existing system.

The key criteria in the new tender for the NDT inspection system were a substantial reduction in inspection times and the option for other measurement and testing methods to be implemented on the system, in addition to the intrinsic ultrasonic inspection. Machine and plant engineering company, Fill, says it offered a solution with two articulated robots on linear axes running in parallel.

In ultrasound inspection by through-transmission, signals coupled by water jet must arrive at the receiver from the transmitter with less than 0.3-mm deviation.

According to Fill, ACCUBOT can inspect workpieces in three separate zones, and jointly in one of them. Automatic tool changing with the Fill FlexChange tool changer is said to enable tests to be conducted with different methods, such as phased array pulse-echo testing or through-transmission inspections with squirter technology, in one clamping operation. X-Ray, tomography, thermography and noncontact methods for geometry measurement can also be integrated in the system. Active Tool, an inspection head from Fill with an additional rotatory axis, enables through-transmission inspection in small, highly contorted areas.

Further, Fill says the system obtains its necessary absolute positioning accuracy through high-precision linear axes and additional rotary encoders fitted on the output side on the rotary axes of the ACCUBOT robots. A robot calibration system based on laser tracker helps achieve and maintain this high-precision subsequently.

Overall, ACCUBOT system incorporation has reduced the time required for annual geometrical inspections at GKN Aerospace from 11 hours to half an hour. The application-independent system software with the Fill STUDIO programming and operating environment has also reportedly brought significant gains in efficiency. It contains a digital twin of the entire system, enables offline programming of the robots during machine operation and features an augmented reality interface.

Fill notes that the system’s large efficiency gain results from significantly quicker inspection processes and the possibility to combine them automatically. “Alone with pulse-echo testing by means of phased array, the inspection time is reduced by 93%,” reports Dr.-Ing. Jakov Šekelja, head of Quality Management at GKN Aerospace Deutschland GmbH. “In addition, the several hours of tactile wall thickness measurement performed subsequently in the past now occurs automatically as a byproduct of the ultrasonic inspection.”

Related Content

SAM XL demonstrates closed-loop digital methodologies via full-size aerocomposite parts development

PeneloPe Project’s modular, zero-defect manufacturing deliverables are being highlighted in an upcoming video that demonstrates the resulting aerospace pilot line’s feasibility.

Read MoreHow AI is improving composites operations and factory sustainability

Workforce pain points and various logistical challenges are putting operations resilience and flexibility to the test, but Industry 4.0 advancements could be the key to composites manufacturers’ transformation.

Read MoreEngel supports composites upcycling research at TH Rosenheim

Engel Group has provided the Rosenheim University of Applied Sciences with a vertical injection molding machine for further R&D into the processing of thermoplastic, recyclable composites and the application of natural fibers.

Read MoreASCEND program completion: Transforming the U.K.'s high-rate composites manufacturing capability

GKN Aerospace, McLaren Automotive and U.K. partners chart the final chapter of the 4-year, £39.6 million ASCEND program, which accomplished significant progress in high-rate production, Industry 4.0 and sustainable composites manufacturing.

Read MoreRead Next

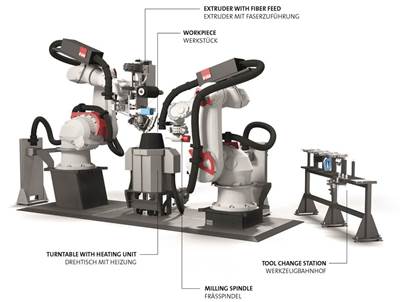

Fill ACCUBOT combines extrusion with continuous fiber additive capabilities

The system’s additive capability, augmented by subtraction via integrated robotic milling creates the potential for the production of cost-effective, high-performance and multifunctional composite components.

Read MoreUltrasonic welding for in-space manufacturing of CFRTP

Agile Ultrasonics and NASA trial robotic-compatible carbon fiber-reinforced thermoplastic ultrasonic welding technology for space structures.

Read MoreCutting 100 pounds, certification time for the X-59 nose cone

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.

Read More